Exploring the Fundamental Principles of Air-Cooled Heat Exchangers

Air-cooled heat exchangers are an integral part of numerous industrial processes, from power generation to chemical manufacturing. These versatile devices harness the power of airflow to facilitate the transfer of heat, making them essential components in a wide range of applications. As an expert in this field, I will guide you through the underlying science and engineering principles that govern the design, operation, and optimization of these remarkable thermal management tools.

The Science of Heat Transfer

At the heart of an air-cooled heat exchanger lies the fundamental principles of heat transfer. Heat can be transferred through three primary mechanisms: conduction, convection, and radiation. In an air-cooled heat exchanger, both convection and conduction play crucial roles in facilitating the exchange of thermal energy.

Conduction, the transfer of heat through direct contact between materials, is essential within the heat exchanger itself. The materials used in the construction, such as metals or composites, must be selected and engineered to efficiently conduct heat from the hot side to the cooler side of the device.

Convection, the transfer of heat through the movement of fluids, is the driving force behind air-cooled heat exchangers. As air flows over the surface of the heat exchanger, it absorbs thermal energy, causing the air temperature to rise. The rate of heat transfer is influenced by factors such as air velocity, surface area, and the temperature difference between the air and the heat exchanger.

Understanding the interplay between conduction and convection is crucial for optimizing the performance of air-cooled heat exchangers. Engineers must carefully design the geometry, materials, and airflow patterns to maximize the transfer of heat and ensure efficient thermal management.

Designing for Efficiency and Effectiveness

The design of air-cooled heat exchangers is a complex and multifaceted process, involving the careful consideration of several key factors. One of the primary objectives is to maximize the heat transfer rate while minimizing energy consumption and maintaining a compact footprint.

Geometric Considerations

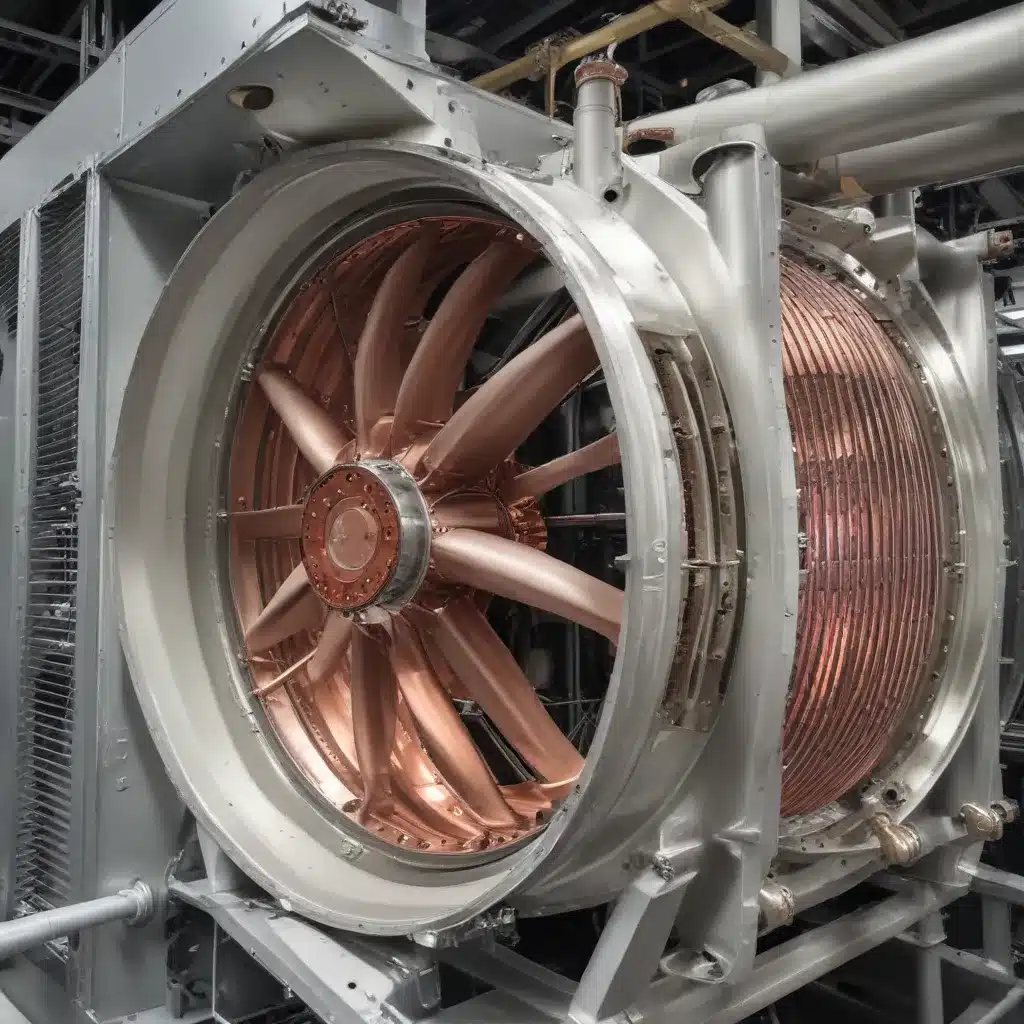

The shape and configuration of the heat exchanger play a significant role in its performance. Factors such as the fin design, tube arrangement, and overall heat transfer surface area can significantly impact the efficiency of the system. Researchers are continuously exploring innovative geometries, such as louvered fins and offset strip fins, to enhance the heat transfer capabilities of air-cooled heat exchangers.

Material Selection

The choice of materials used in the construction of an air-cooled heat exchanger is critical. Common materials include aluminum, copper, and stainless steel, each with its own unique properties and trade-offs. Factors such as thermal conductivity, corrosion resistance, and durability must be carefully weighed to ensure the optimal performance and lifespan of the heat exchanger.

Airflow Management

Efficient airflow management is a key aspect of air-cooled heat exchanger design. The arrangement and orientation of the heat exchanger, as well as the design of the fan or blower system, can significantly impact the airflow patterns and, consequently, the heat transfer rate. Computational fluid dynamics (CFD) simulations and experimental testing are often employed to optimize the airflow characteristics and improve the overall system efficiency.

Thermal-Hydraulic Optimization

Achieving the right balance between thermal and hydraulic performance is crucial for air-cooled heat exchangers. Engineers must consider the tradeoffs between heat transfer, pressure drop, and energy consumption to design a system that delivers the desired thermal performance while minimizing operational costs.

Maintenance and Optimization Strategies

Maintaining the optimal performance of air-cooled heat exchangers is essential for ensuring reliable and efficient operations. Regular inspections, cleaning, and preventive maintenance are crucial to address common challenges and extend the lifespan of these critical components.

Fouling and Cleaning Strategies

Fouling, the accumulation of contaminants on the heat exchanger surfaces, can significantly reduce the system’s heat transfer efficiency. Implementing effective cleaning strategies, such as chemical or mechanical cleaning, is essential for maintaining the heat exchanger’s performance over time.

Corrosion and Material Degradation

Air-cooled heat exchangers can be susceptible to corrosion and material degradation, particularly in harsh environments or when exposed to aggressive media. Selecting appropriate materials and implementing corrosion mitigation strategies, such as coatings or cathodic protection, can help extend the lifespan of the equipment.

Performance Monitoring and Optimization

Continuous monitoring of key performance indicators, such as temperature differences, pressure drops, and airflow rates, can provide valuable insights into the health and efficiency of the air-cooled heat exchanger. By leveraging advanced monitoring technologies and data analytics, operators can identify optimization opportunities, plan maintenance activities, and maximize the overall system performance.

Industrial Applications and Emerging Trends

Air-cooled heat exchangers find widespread use across various industries, including power generation, petrochemical processing, HVAC systems, and transportation. As technology advances, new applications and innovative designs are constantly emerging, pushing the boundaries of thermal engineering.

Power Generation and Energy Efficiency

In the power generation sector, air-cooled heat exchangers play a crucial role in the cooling of steam turbines, condensers, and other critical components. Improving the efficiency of these systems can contribute significantly to the overall energy efficiency of power plants, reducing operational costs and environmental impact.

Process Industries and Chemical Manufacturing

Air-cooled heat exchangers are essential in the chemical, petrochemical, and pharmaceutical industries, where they facilitate the cooling and heating of process streams, reactors, and other equipment. Tailored designs and materials selection are crucial to address the unique challenges posed by corrosive or fouling media in these applications.

Heating, Ventilation, and Air Conditioning (HVAC)

In the HVAC industry, air-cooled heat exchangers are integral to the design of chillers, condensers, and other cooling systems. Optimizing the heat transfer performance and minimizing energy consumption are key priorities in this sector, driving the development of more efficient and environmentally friendly cooling technologies.

Emerging Trends and Innovations

As the world strives for greater energy efficiency and sustainability, the field of air-cooled heat exchangers is witnessing exciting advancements. These include the integration of advanced materials, such as nanomaterials and composites, to enhance heat transfer capabilities, the implementation of intelligent control systems for optimized operations, and the exploration of hybrid cooling solutions that combine air-cooling with other thermal management strategies.

Conclusion

Air-cooled heat exchangers are essential components in a wide range of industries, playing a crucial role in thermal management and energy efficiency. By understanding the fundamental principles of heat transfer, design optimization, and maintenance strategies, engineers and technicians can unlock the full potential of these versatile devices. As the world continues to demand more efficient and sustainable solutions, the field of air-cooled heat exchangers remains at the forefront of thermal engineering, offering a wealth of opportunities for innovation and progress.

At the Air Cooled Heat Exchangers blog, we are dedicated to providing our readers with the latest insights, practical tips, and in-depth knowledge to help them navigate the complexities of this dynamic field. Whether you are an industry professional, a researcher, or simply curious about the science behind air-cooled heat exchangers, we invite you to explore our comprehensive resources and embark on a journey of discovery in the realm of thermal engineering.