Mastering the Fundamentals of Thermal Management

In the ever-evolving realm of modern electronics, efficient thermal management stands as a cornerstone for ensuring optimal performance and longevity. At the heart of this thermal management ecosystem lie air-cooled heat exchangers – passive cooling devices that play a crucial role in dissipating excess heat generated by electronic components. As seasoned experts in the field, we’re here to unravel the science behind these unsung heroes of thermal engineering, providing you with practical insights and in-depth understanding to optimize the cool composure of your electronic systems.

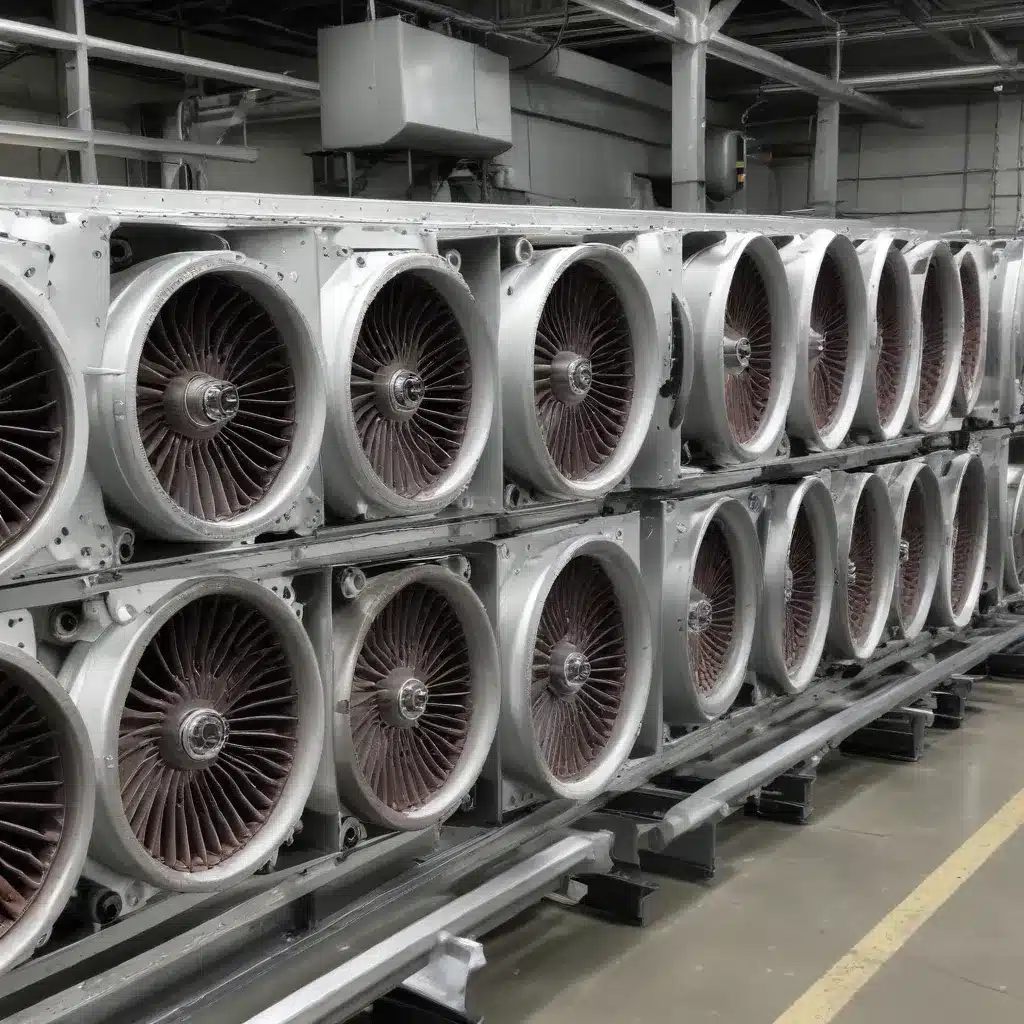

The Purpose of Air-Cooled Heat Exchangers

Electronic devices, from smartphones and laptops to high-performance servers, rely on the flow of electrical current to process information and perform various tasks. This very process, however, comes with an inherent consequence – the generation of heat. Heat is a natural byproduct of the electrical resistance encountered within the components and circuitry of these devices. While a certain level of heat generation is inevitable and considered normal, excessive heat poses a significant threat to the performance, reliability, and longevity of electronic components.

When electronic components operate under high temperatures, several adverse effects may occur:

- Reduced Efficiency: Elevated temperatures can lead to decreased energy efficiency, as the electronic components struggle to maintain their optimal performance levels.

- Accelerated Wear and Tear: Excessive heat can cause premature aging and degradation of electronic components, leading to a shorter lifespan and more frequent failures.

- Thermal Throttling: Many electronic devices, such as CPUs and GPUs, employ thermal throttling mechanisms to protect themselves from overheating, which can result in reduced processing power and performance.

- Instability and Malfunctions: Extreme heat can cause electronic circuits to become unstable, leading to system crashes, data corruption, and other malfunctions.

To mitigate these challenges and keep electronic devices operating within their safe temperature limits, air-cooled heat exchangers have emerged as a critical technology. These passive cooling devices play a pivotal role in transferring and dissipating the excess heat generated by electronic components, ensuring their reliable and optimal performance.

The Science of Air-Cooled Heat Exchangers

At the core of an air-cooled heat exchanger’s operation lies the fundamental principles of heat transfer: conduction, convection, and radiation. By leveraging these principles, heat exchangers efficiently transfer heat from the electronic component to the surrounding environment, maintaining a cool and stable operating temperature.

Conductive Heat Transfer

Conductive heat transfer is the first stage in the heat dissipation process. When an electronic component, such as a CPU or GPU, operates, it generates heat due to the flow of electrical current. This heat is conducted through the component’s metal or semiconductor substrate and transferred to the heat exchanger via direct contact.

The efficiency of conductive heat transfer depends on the thermal conductivity of the materials involved and the quality of the contact between the electronic component and the heat exchanger. Materials with higher thermal conductivity, such as metals like copper and aluminum, are preferred for heat exchanger construction, as they can more effectively transfer heat.

Convective Heat Transfer

Once the heat is conducted to the heat exchanger, the next step is to dissipate it into the surrounding air through convective heat transfer. This process relies on the movement of air across the heat exchanger’s surface, which can be either natural or forced.

Natural convection occurs when the heated air surrounding the heat exchanger rises due to its lower density, creating a flow of cooler air to take its place. This natural airflow aids in heat dissipation and is commonly found in passive heat exchanger designs.

Forced convection, on the other hand, utilizes external fans or blowers to actively move air across the heat exchanger’s surface. The forced airflow significantly enhances the cooling efficiency, making forced convection ideal for high-power electronic components and devices.

To optimize convective heat transfer, heat exchangers are often designed with fin structures that maximize the surface area exposed to the surrounding air. This increased surface area allows for better heat dissipation and helps maintain the heat exchanger’s temperature within an acceptable range.

Radiative Heat Transfer

In addition to conductive and convective heat transfer, radiative heat transfer also plays a role in the overall heat dissipation process, though its significance is generally less pronounced for typical electronic devices.

Radiative heat transfer occurs through the emission of electromagnetic waves, including infrared radiation, from objects with a temperature above absolute zero. In the context of heat exchangers, radiative heat transfer becomes more relevant when dealing with extremely high-temperature components and environments.

By understanding these three modes of heat transfer – conduction, convection, and radiation – engineers can design effective air-cooled heat exchanger solutions that efficiently dissipate heat and maintain the cool composure of electronic components.

Optimizing Heat Exchanger Design and Performance

The performance of an air-cooled heat exchanger is heavily influenced by its design and the choice of materials used in its construction. Careful consideration of these factors can lead to significant improvements in heat dissipation capabilities.

Heatsink Materials

The two most commonly used materials for heat exchangers are aluminum and copper. Both materials offer distinct advantages:

- Aluminum: Lightweight, affordable, and has moderate thermal conductivity. Aluminum heat exchangers are widely used in a variety of applications due to their cost-effectiveness and reasonable cooling performance.

- Copper: Offers superior thermal conductivity compared to aluminum, resulting in more efficient heat transfer. Copper heat exchangers are often used in high-performance applications where cooling efficiency is paramount, though they tend to be more expensive.

The choice between aluminum and copper, or even a combination of the two, depends on the specific cooling requirements, available space, and budgetary constraints of the electronic system.

Fin Design

The fin design of a heat exchanger plays a crucial role in its cooling performance. Fins serve to increase the surface area of the heat exchanger, allowing for better heat dissipation through convective cooling. Several fin designs are commonly employed, including:

- Straight Fins: The most basic and widely used fin design, featuring parallel, straight fins extending from the heat exchanger’s base.

- Spiral Fins: Fins arranged in a spiral pattern, which can enhance airflow and improve heat transfer.

- Pin Fins: Cylindrical pin-shaped fins that offer a high surface area-to-volume ratio, making them suitable for compact spaces.

- Offset Strip Fins: Fins arranged in a staggered pattern, creating turbulence in the airflow and increasing heat transfer.

The choice of fin design depends on factors such as the available space, airflow conditions, and the specific cooling requirements of the electronic device.

Advanced Cooling Technologies

To further enhance the heat dissipation capabilities of air-cooled heat exchangers, engineers have developed advanced cooling technologies, such as heat pipes and vapor chambers.

Heat Pipes: Heat pipes are passive, two-phase heat transfer devices that efficiently transport heat from one location to another. They rely on the principles of evaporation and condensation to move heat with minimal temperature gradients, making them highly effective in transferring heat from a hot electronic component to a remote heat exchanger.

Vapor Chambers: Vapor chambers are advanced variants of heat pipes that offer superior thermal conductivity and are particularly effective in spreading heat across large surfaces. Vapor chambers consist of a sealed chamber filled with a working fluid, which evaporates and condenses to distribute heat uniformly across the entire surface.

By incorporating these advanced cooling technologies, air-cooled heat exchangers can provide more efficient and effective thermal management, especially in high-power electronic devices where heat dissipation is a critical challenge.

Cooling Critical Components: CPUs, GPUs, and Beyond

Air-cooled heat exchangers play a vital role in maintaining the cool composure of the most power-hungry components in electronic devices – central processing units (CPUs) and graphics processing units (GPUs).

CPUs and GPUs are responsible for the heavy lifting in computers and gaming systems, generating substantial amounts of heat during operation. Efficient cooling is essential to prevent thermal throttling, which can significantly impact the performance and reliability of these critical components.

In computer systems, CPU heat exchangers are typically attached directly to the CPU using thermal interface materials (TIMs) like thermal paste or thermal pads. These heat exchangers absorb the heat generated by the CPU and transfer it away to the surrounding air, often with the aid of integrated fans for enhanced cooling performance.

Similarly, in high-performance gaming systems and graphics cards, GPUs generate significant heat during intense graphics processing tasks. GPU heat exchangers, often combined with heat pipes and/or vapor chambers, are employed to effectively dissipate the heat generated by the GPU, ensuring optimal gaming performance without thermal throttling.

Beyond CPUs and GPUs, air-cooled heat exchangers are also extensively used in LED lighting fixtures and power electronics applications, where efficient thermal management is crucial for reliability and performance.

In LED lighting fixtures, the heat generated by LEDs can negatively impact their performance and lifespan if not properly managed. LED heat exchangers are designed to draw away the excess heat, ensuring efficient cooling and extending the lifetime of the lighting fixtures.

Power electronics, such as power supplies, motor drives, and inverters, handle high electrical power levels, leading to considerable heat generation. Effective thermal management is essential for ensuring the reliability and longevity of these power electronics components, and air-cooled heat exchangers play a vital role in dissipating the generated heat.

By employing properly designed and engineered air-cooled heat exchangers, electronic systems can operate reliably and efficiently, delivering high performance while maintaining the cool composure of critical components.

Bridging the Gap: Thermal Interface Materials

Thermal interface materials (TIMs) play a critical role in the efficient transfer of heat between electronic components and heat exchangers. As electronic devices continue to push performance boundaries, effective thermal management becomes paramount, and TIMs serve as the crucial link between the heat source and the cooling solution.

TIMs bridge the microscopic gaps and imperfections between the mating surfaces of the electronic component and the heat exchanger, ensuring a low-resistance thermal pathway for heat dissipation. To optimize heat transfer and minimize thermal resistance, adhering to best practices when applying TIMs is crucial:

- Proper Surface Preparation: Ensuring clean and smooth surfaces on both the component and the heat exchanger is essential for effective TIM application.

- Accurate Thickness Control: Applying the appropriate amount of TIM, often in the range of 0.1 to 0.2 millimeters, is crucial for optimal heat transfer.

- Uniform Coverage: Evenly distributing the TIM across the entire contact area between the component and the heat exchanger is key to avoiding hot spots and ensuring efficient cooling.

- Thermal Conductivity: Selecting a TIM with high thermal conductivity, such as thermal pastes or phase-change materials, can significantly enhance the overall heat transfer efficiency.

By following these best practices, engineers can create a reliable and effective thermal interface, enabling electronic devices to operate at peak performance while maintaining the cool composure of critical components.

Pushing the Boundaries: Advanced Cooling Techniques

As the demand for high-performance and compact electronic devices continues to escalate, the thermal management challenges faced by engineers have become increasingly complex. Traditional air-cooled heat exchangers, while effective in many applications, may fall short in addressing the cooling requirements of high-power electronics within limited form factors.

To overcome these limitations, engineers and researchers have developed advanced cooling techniques that push the boundaries of thermal management. These innovative solutions harness the principles of thermodynamics and utilize cutting-edge materials and technologies to provide unparalleled cooling capabilities.

Liquid Cooling Systems

Liquid cooling systems, including all-in-one (AIO) liquid coolers and custom loop solutions, offer enhanced cooling capabilities for high-performance applications. By utilizing a liquid coolant, such as water or specialized fluids, these systems can achieve superior heat transfer efficiency compared to air-cooled heat exchangers.

The liquid coolant circulates through a closed loop, absorbing heat from the electronic component and dissipating it through a heat exchanger or radiator. The use of liquid cooling can provide improved thermal performance, reduced noise levels, and better overall system stability in power-hungry applications like gaming PCs, high-end workstations, and data centers.

Phase Change Cooling

Phase change cooling is a cutting-edge cooling technique that offers unparalleled thermal management capabilities for specialized applications with stringent cooling requirements. This advanced method harnesses the principles of thermodynamics to achieve extreme cooling by utilizing the phase transitions of refrigerants or thermoelectric modules.

Refrigeration-based Phase Change Cooling: Refrigeration-based cooling systems leverage the phase transitions of refrigerants to absorb and dissipate heat, enabling ultra-low temperature maintenance. These systems are commonly used in industrial, medical, and scientific applications where precise and consistent cooling is critical.

Thermoelectric Cooling: Thermoelectric cooling, also known as the Peltier effect, is a solid-state cooling technique that relies on the behavior of certain semiconductor materials. When an electric current flows through a thermoelectric module, one side absorbs heat while the other side releases it, creating a cooling effect. Thermoelectric cooling is often employed in specialized applications where compact and precise cooling is essential.

By exploring these advanced cooling techniques, engineers can address the growing demands for efficient thermal management in high-power electronics, pushing the boundaries of what is possible in maintaining the cool composure of cutting-edge devices.

Overcoming Cooling Challenges in High-Power Electronics

As electronic devices continue to push the boundaries of performance and functionality, the demand for high-power electronics has grown exponentially. High-power electronic components, such as power transistors, inverters, and high-performance processors, are capable of handling substantial electrical currents to deliver efficient power conversion and data processing.

However, the increased power density comes with a significant challenge – managing the heat generated by these power-hungry devices. Power density refers to the amount of power dissipated per unit volume or area of the electronic component. High-power electronics can generate a substantial amount of heat within a confined space, leading to localized hotspots and temperature spikes.

In such power-dense applications, traditional cooling methods may prove inadequate, necessitating advanced cooling techniques to ensure the components operate within their safe temperature limits. Some of the conventional cooling methods employed in high-power electronics include:

- Air-Cooled Heat Exchangers: Passive cooling solutions that rely on conductive and convective heat transfer to dissipate heat.

- Forced Air Cooling: Active cooling systems that utilize fans or blowers to enhance air circulation and heat dissipation.

- Liquid Cooling: Closed-loop systems that circulate a liquid coolant to absorb and transfer heat more efficiently than air-based cooling.

To address the cooling challenges posed by high-power electronics, engineers and researchers have developed several advanced cooling techniques:

Microfin Heatsinks: Heatsinks with microscopic fins that drastically increase the surface area for enhanced heat dissipation in compact spaces.

Vapor Chambers: Advanced heat transfer devices that efficiently spread heat across large surfaces, improving thermal management in high-power applications.

Graphene-based Heatsinks: Innovative solutions that leverage the exceptional thermal properties of graphene to enhance heat transfer and dissipation.

Embedded Cooling Solutions: Integrated cooling systems that are designed and optimized within the electronic device, providing efficient and tailored thermal management.

The success of these advanced cooling techniques lies not only in their implementation but also in their integration and optimization within the electronic device. Designing efficient cooling solutions involves considering factors such as material selection, coolant flow rates, heat exchanger design, and thermal interface materials to ensure optimal heat dissipation.

By embracing these cutting-edge cooling technologies, engineers can overcome the challenges posed by high-power electronics, maintaining the cool composure of these power-hungry components and ensuring reliable, high-performance electronic systems.

Conclusion: Maintaining the Cool Composure of Electronics

In the world of electronics, air-cooled heat exchangers stand as a cornerstone of efficient thermal management. By understanding the principles and mechanics behind heat exchanger cooling, we empower ourselves to create robust cooling solutions that preserve the performance and longevity of our electronic devices.

From the fundamental principles of heat transfer to the advanced cooling techniques, we have unraveled the science behind air-cooled heat exchangers, equipping ourselves with the knowledge to maintain the cool composure of our electronics. By leveraging conductive, convective, and radiative heat transfer, engineers can design and optimize heat exchanger solutions tailored to the specific needs of various electronic systems.

As technology continues to push the boundaries of performance and functionality, the demand for efficient thermal management will only grow. The insights and practical tips shared in this article will serve as a valuable resource for engineers, technicians, and enthusiasts alike, empowering them to tackle the evolving challenges in the world of air-cooled heat exchangers.

Embracing the science of heat exchanger cooling is an endeavor to ensure a future of reliable and high-performance electronic systems, where the cool composure of our devices is the cornerstone of their success. Explore the world of air-cooled heat exchangers at https://www.aircooledheatexchangers.net/ to discover more about the cutting-edge solutions that keep our electronics running at their best.