The Fundamentals of Air-Cooled Heat Exchangers

Air-cooled heat exchangers are a vital component in a wide range of industries, from manufacturing and power generation to HVAC and cryogenic applications. These versatile devices play a crucial role in efficiently transferring heat between two fluids, often using air as the cooling medium. Understanding the core principles behind air-cooled heat exchangers is essential for optimizing their design, performance, and maintenance.

At the heart of an air-cooled heat exchanger is the concept of thermal energy transfer. As one fluid (typically a liquid or gas) passes through the exchanger, it transfers its heat to the surrounding air. The air is then heated and expelled, carrying away the excess thermal energy. This process is driven by the temperature difference between the two fluids, with the hotter fluid transferring its heat to the cooler air.

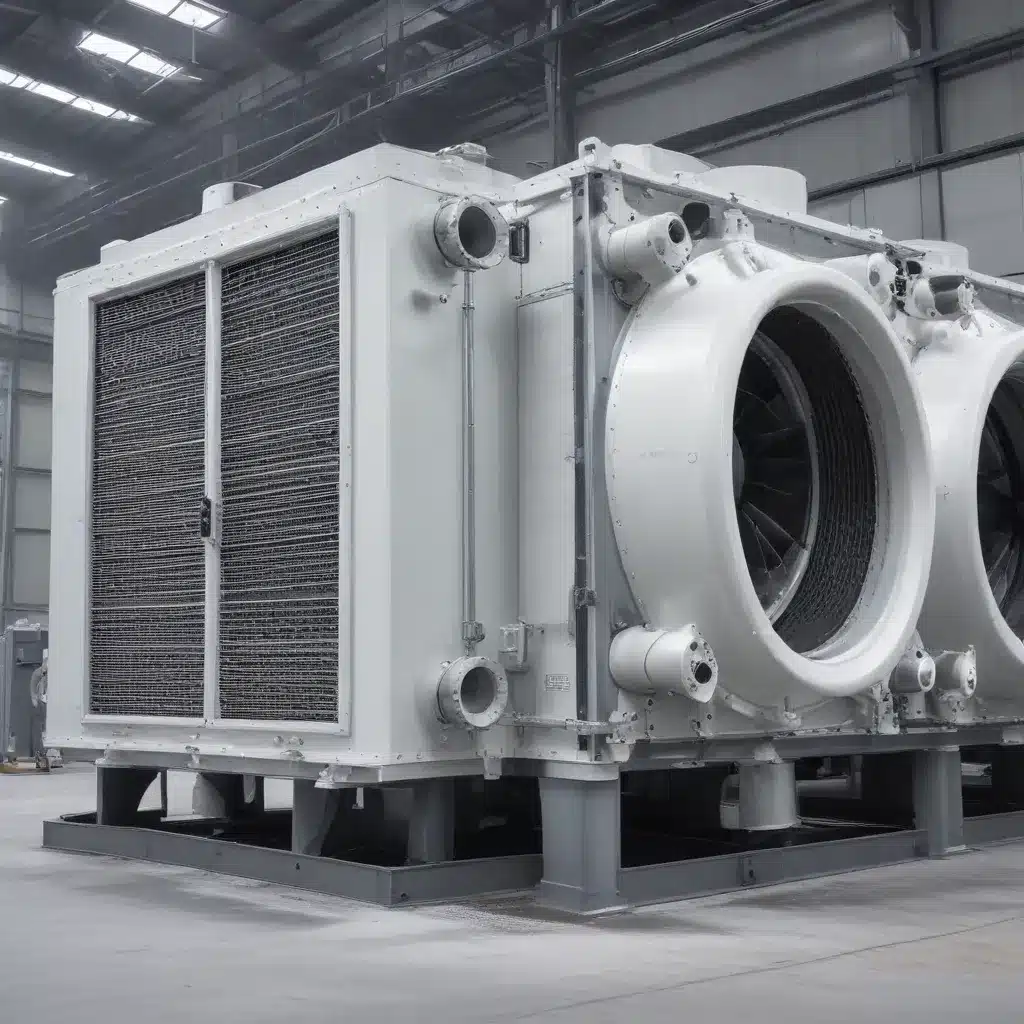

The design of air-cooled heat exchangers can vary significantly, depending on the specific application and operating conditions. Some common configurations include finned tube exchangers, plate-fin exchangers, and spiral-wound exchangers, each with their own advantages and considerations. The choice of materials, fin geometry, and air flow patterns can all impact the overall efficiency and performance of the system.

Optimizing Air-Cooled Heat Exchanger Performance

One of the key factors in maximizing the performance of air-cooled heat exchangers is ensuring efficient heat transfer between the process fluid and the cooling air. This can be achieved through careful design of the heat transfer surface, including the selection of fin materials, fin density, and fin geometry. By optimizing these parameters, engineers can enhance the overall heat transfer coefficient, leading to improved cooling capacity and reduced energy consumption.

Another important aspect of air-cooled heat exchanger performance is the management of air flow. Proper air flow distribution and minimizing air-side pressure drops are critical for maintaining optimal heat transfer rates. This can be accomplished through the use of strategically placed fans, baffles, and airflow management systems, which ensure that the cooling air is evenly distributed across the heat exchanger surface.

Maintaining optimal operating conditions is also essential for sustaining the long-term performance of air-cooled heat exchangers. Regular maintenance, including cleaning the heat transfer surfaces, inspecting for fouling, and ensuring proper air flow, can help prevent degradation in efficiency and extend the service life of the equipment.

Applications of Air-Cooled Heat Exchangers

Air-cooled heat exchangers find a wide range of applications across various industries, each with its own unique challenges and requirements.

Industrial Cooling Applications

In the manufacturing and power generation sectors, air-cooled heat exchangers play a crucial role in cooling process fluids, such as lubricating oils, hydraulic fluids, and coolants. By effectively removing excess heat, these exchangers help maintain the optimal operating conditions for industrial machinery, ensuring efficient and reliable performance.

One example of an industrial application is the use of air-cooled heat exchangers in power plants, where they are employed to cool the steam condensate or generator cooling water. This helps improve the overall thermal efficiency of the power generation process, reducing energy consumption and operating costs.

HVAC Systems

Air-cooled heat exchangers are also extensively used in heating, ventilation, and air conditioning (HVAC) systems, where they are responsible for transferring heat between the refrigerant and the surrounding air. In air conditioning units, for instance, the air-cooled condenser unit utilizes an air-cooled heat exchanger to dissipate the heat absorbed from the indoor environment, allowing the system to maintain the desired cooling effect.

Cryogenic Applications

The versatility of air-cooled heat exchangers extends beyond industrial and HVAC applications, reaching into the realm of cryogenic systems. In cryogenic applications, air-cooled exchangers are used to cool various components and fluids, such as superconducting magnets, liquid nitrogen, and liquid helium, to extremely low temperatures.

One notable example is the use of air-cooled heat exchangers in the cooling systems of particle accelerators and fusion reactors, where they play a critical role in maintaining the optimal operating temperatures of superconducting magnets. These specialized exchangers must be designed to withstand the challenging cryogenic environment while ensuring efficient heat transfer.

Innovations in Air-Cooled Heat Exchanger Technology

As the demand for more efficient and versatile heat exchange solutions continues to grow, the field of air-cooled heat exchangers has seen significant advancements in recent years. Engineers and researchers are exploring innovative materials, designs, and integration strategies to push the boundaries of what is possible.

Advanced Materials and Coatings

The selection of materials used in air-cooled heat exchangers is crucial for their performance and durability. Ongoing research has led to the development of new materials, such as high-performance alloys and specialized coatings, that can enhance the heat transfer capabilities, corrosion resistance, and fouling resistance of these exchangers.

For example, the use of aluminum alloys has become increasingly common, as they offer a favorable balance of thermal conductivity, weight, and cost-effectiveness. Additionally, the application of hydrophilic or hydrophobic coatings can help manage condensation and improve air-side heat transfer, further enhancing the overall efficiency of the system.

Integrated Thermal Management Systems

The integration of air-cooled heat exchangers into broader thermal management systems is another area of innovation. By combining these exchangers with advanced control systems, heat recovery mechanisms, and integrated cooling loops, engineers can create highly efficient and optimized cooling solutions for complex industrial and cryogenic applications.

These integrated systems leverage the versatility of air-cooled heat exchangers to not only dissipate heat but also capture and redistribute thermal energy, reducing overall energy consumption and environmental impact.

Computational Fluid Dynamics (CFD) Modeling

The use of computational fluid dynamics (CFD) modeling has become an invaluable tool in the design and optimization of air-cooled heat exchangers. By simulating the complex airflow and heat transfer dynamics within these systems, engineers can identify areas for improvement, optimize fin geometries, and predict performance under a wide range of operating conditions.

CFD modeling enables designers to iterate on their concepts more efficiently, reducing the need for costly physical prototypes and experimental testing. This, in turn, accelerates the development of innovative air-cooled heat exchanger designs that push the boundaries of performance and efficiency.

Maintaining and Troubleshooting Air-Cooled Heat Exchangers

Proper maintenance and troubleshooting are crucial for ensuring the long-term reliability and performance of air-cooled heat exchangers. Regular inspections, cleaning, and preventive maintenance are essential to address common issues and optimize the exchanger’s operation.

Cleaning and Fouling Prevention

One of the primary maintenance concerns for air-cooled heat exchangers is the accumulation of dirt, debris, and other contaminants on the heat transfer surfaces. This fouling can significantly reduce the exchanger’s efficiency, leading to decreased cooling capacity and increased energy consumption.

To mitigate this issue, regular cleaning of the heat transfer surfaces, including the fins and tubes, is recommended. This can be done using various methods, such as high-pressure water washing, chemical cleaning, or mechanical brushing, depending on the specific type and application of the exchanger.

Additionally, the implementation of preventive measures, such as air filtration systems and regular inspections, can help minimize the accumulation of fouling materials and extend the time between cleaning cycles.

Airflow Management and Fan Maintenance

Proper airflow management is essential for maintaining the optimal performance of air-cooled heat exchangers. Regular inspection and maintenance of the fans, including cleaning the blades and ensuring proper air flow distribution, can help prevent issues such as air-side pressure drops and uneven heat transfer.

In some cases, the installation of airflow monitoring and control systems can further enhance the efficiency of the air-cooled heat exchanger by automatically adjusting the fan speed and air flow to match the changing cooling requirements.

Vibration and Corrosion Monitoring

Air-cooled heat exchangers can be susceptible to vibration-induced damage and corrosion, especially in industrial environments. Implementing a preventive maintenance program that includes regular vibration monitoring and corrosion inspections can help identify potential issues before they escalate, allowing for timely repairs and preventive actions.

The use of advanced monitoring techniques, such as online vibration monitoring and corrosion detection sensors, can provide valuable insights into the overall health of the heat exchanger, enabling proactive maintenance and extending the lifespan of the equipment.

Conclusion

Air-cooled heat exchangers have proven to be a versatile and essential technology across a wide range of industries, from industrial cooling and HVAC systems to cryogenic applications. Their ability to efficiently transfer heat using air as the cooling medium has made them indispensable in modern industrial and scientific processes.

As the demand for sustainable and energy-efficient solutions continues to grow, the innovations in air-cooled heat exchanger technology are driving advancements in materials, design, and integration strategies. By optimizing heat transfer, airflow management, and maintenance practices, engineers and researchers are unlocking new possibilities for these vital components, paving the way for a more efficient and environmentally conscious future.

Whether you’re working in industrial manufacturing, power generation, HVAC, or cryogenic research, understanding the fundamentals and best practices of air-cooled heat exchangers is crucial for ensuring reliable performance, reducing energy consumption, and contributing to the overall sustainability of your operations. By leveraging the versatility of these heat exchangers, you can unlock new levels of efficiency and innovation in your field.