Understanding the Fundamentals of Air-Cooled Heat Exchangers

Air-cooled heat exchangers play a crucial role in a wide range of industrial and commercial applications, from power generation to HVAC systems. These versatile devices are designed to efficiently dissipate waste heat by using air as the cooling medium. Understanding the inner workings and key components of air-cooled heat exchangers is essential for ensuring their optimal performance and longevity.

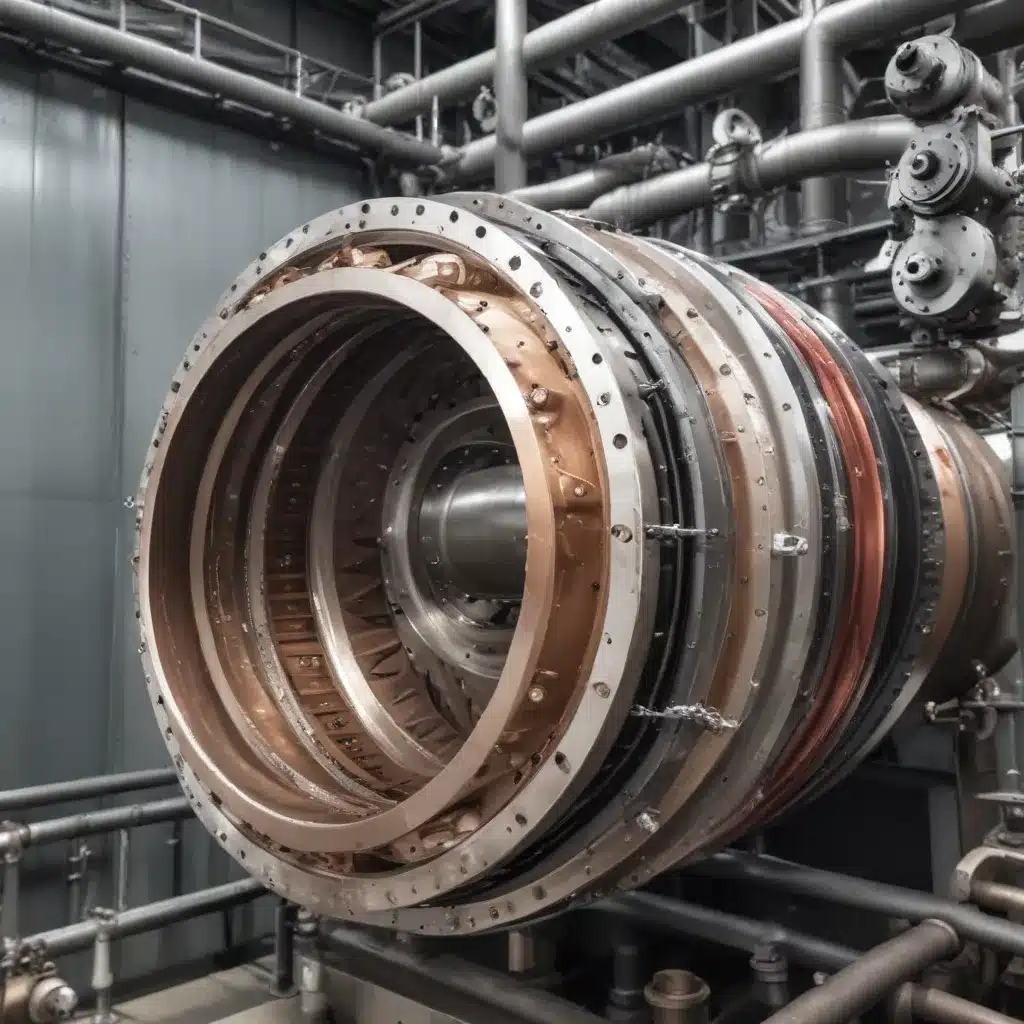

At the heart of an air-cooled heat exchanger lies the heat transfer process. As warm fluid, such as water or a refrigerant, flows through the exchanger, heat is transferred from the fluid to the surrounding air. This heat exchange is facilitated by a network of tubes or plates, often made of materials with high thermal conductivity, such as copper or aluminum. As the air flows over these components, it absorbs the heat, effectively lowering the temperature of the fluid.

The design and configuration of an air-cooled heat exchanger can vary depending on the specific application and operational requirements. Common types include:

- Fin-and-Tube Heat Exchangers: These feature a series of tubes with attached fins, which increase the surface area for more efficient heat transfer.

- Plate-Fin Heat Exchangers: These utilize a stacked arrangement of thin metal plates and fins to maximize the heat exchange surface area.

- Microchannel Heat Exchangers: These compact designs feature small, parallel microchannels that enhance the heat transfer rate and reduce the overall size of the exchanger.

Each design offers unique advantages, and the choice depends on factors such as the required cooling capacity, available space, and the characteristics of the fluid being cooled.

Maintaining Optimal Heat Exchanger Performance

Ensuring the optimal performance of air-cooled heat exchangers requires a comprehensive maintenance strategy. Regular inspections, cleaning, and adjustments can significantly improve efficiency, extend the system’s lifespan, and prevent unexpected breakdowns.

Cleaning and Maintenance

One of the most critical maintenance tasks for air-cooled heat exchangers is regular cleaning. Over time, dirt, debris, and other contaminants can accumulate on the heat transfer surfaces, reducing the exchanger’s efficiency. Regularly cleaning the fins, tubes, and other components using appropriate cleaning agents and methods can restore the heat transfer capacity and maintain optimal performance.

In addition to cleaning, it’s essential to inspect the heat exchanger for any signs of wear or damage, such as corrosion, leaks, or mechanical issues. Addressing these issues promptly can prevent further deterioration and costly repairs down the line.

Airflow Optimization

Maintaining proper airflow through the heat exchanger is crucial for efficient heat dissipation. Factors such as fan operation, air inlet and outlet conditions, and the cleanliness of the heat transfer surfaces can all impact the airflow. Regular inspections and adjustments to the fan speed, air baffles, and other components can help ensure optimal airflow and heat transfer.

Monitoring and Diagnostics

Regularly monitoring the operating parameters of the air-cooled heat exchanger, such as fluid temperatures, pressures, and flow rates, can provide valuable insights into the system’s performance. By analyzing these data points, you can identify any deviations from the expected operating conditions and take corrective actions before minor issues escalate into more significant problems.

Seasonal Considerations

The performance of air-cooled heat exchangers can be significantly affected by seasonal changes in ambient temperature and humidity. During the warmer months, the exchanger may need to work harder to dissipate heat, while in colder climates, the risk of freezing and icing increases. Implementing seasonal maintenance routines, such as winterizing the system or adjusting fan speeds, can help ensure consistent, reliable, and efficient operation throughout the year.

Optimizing Air-Cooled Heat Exchanger Performance

Beyond regular maintenance, there are several strategies and techniques that can be employed to optimize the performance of air-cooled heat exchangers. These include:

Enhancing Heat Transfer Efficiency

Innovations in materials, coatings, and surface geometries can significantly improve the heat transfer efficiency of air-cooled heat exchangers. For example, using high-conductivity materials, such as copper or aluminum, or applying specialized coatings that reduce fouling can enhance the overall heat transfer rate.

Improving Airflow Management

Optimizing the airflow through the heat exchanger can have a significant impact on its performance. This can be achieved through the use of computational fluid dynamics (CFD) analysis to identify and address airflow bottlenecks, as well as the incorporation of advanced fan and duct designs.

Leveraging Hybrid Cooling Systems

In some applications, combining air-cooled heat exchangers with other cooling technologies, such as evaporative or water-cooled systems, can provide a more comprehensive and efficient cooling solution. These hybrid systems can offer improved performance, reduced energy consumption, and enhanced flexibility to accommodate varying cooling demands.

Incorporating Predictive Maintenance

By integrating advanced monitoring and analytics capabilities, air-cooled heat exchangers can be transformed into “smart” systems capable of predicting maintenance needs and potential issues. This proactive approach, known as predictive maintenance, can help minimize downtime, optimize equipment lifespan, and improve overall system reliability.

Unlocking the Full Potential of Air-Cooled Heat Exchangers

Air-cooled heat exchangers are essential components in a wide range of industrial and commercial applications, playing a crucial role in maintaining optimal operating conditions and energy efficiency. By understanding the fundamental principles of these systems, implementing comprehensive maintenance strategies, and exploring innovative optimization techniques, you can unlock the full potential of your air-cooled heat exchangers.

At Air Cooled Heat Exchangers, we are dedicated to providing our clients with the knowledge and expertise needed to maximize the performance and longevity of their heat exchange systems. Whether you’re seeking guidance on maintenance best practices, insights into the latest industry innovations, or customized solutions to meet your unique cooling requirements, our team of experts is here to assist you every step of the way.

Explore our comprehensive resource library to delve deeper into the world of air-cooled heat exchangers and discover how these essential components can contribute to the success of your operations.

Maintenance Strategies for Air-Cooled Heat Exchangers

Ensuring the optimal performance and longevity of air-cooled heat exchangers requires a proactive approach to maintenance. By implementing a comprehensive maintenance strategy, you can maximize the efficiency, reliability, and service life of these critical components.

Cleaning and Inspection

Regularly cleaning the heat exchanger is a crucial maintenance task. Over time, air-borne contaminants, such as dust, dirt, and grease, can accumulate on the heat transfer surfaces, reducing the exchanger’s efficiency. Implementing a routine cleaning schedule, using appropriate cleaning agents and methods, can restore the heat transfer capacity and maintain optimal performance.

In addition to cleaning, regular inspections are essential to identify any signs of wear, damage, or degradation. This includes checking for corrosion, leaks, and structural integrity, as well as inspecting the fan, motor, and other mechanical components. Addressing these issues promptly can prevent further deterioration and costly repairs.

Airflow Management

Maintaining proper airflow through the heat exchanger is crucial for efficient heat dissipation. Factors such as fan operation, air inlet and outlet conditions, and the cleanliness of the heat transfer surfaces can all impact the airflow. Regularly inspecting and adjusting the fan speed, air baffles, and other components can help ensure optimal airflow and heat transfer.

Monitoring and Diagnostics

Continuously monitoring the operating parameters of the air-cooled heat exchanger, such as fluid temperatures, pressures, and flow rates, can provide valuable insights into the system’s performance. By analyzing these data points, you can identify any deviations from the expected operating conditions and take corrective actions before minor issues escalate into more significant problems.

Seasonal Considerations

The performance of air-cooled heat exchangers can be significantly affected by seasonal changes in ambient temperature and humidity. During the warmer months, the exchanger may need to work harder to dissipate heat, while in colder climates, the risk of freezing and icing increases. Implementing seasonal maintenance routines, such as winterizing the system or adjusting fan speeds, can help ensure consistent, reliable, and efficient operation throughout the year.

Preventive Maintenance

Adopting a preventive maintenance approach can help extend the lifespan of your air-cooled heat exchangers and minimize the risk of unexpected breakdowns. This includes regularly scheduled inspections, component replacements (e.g., air filters, gaskets), and proactive repairs to address potential issues before they escalate.

By implementing a comprehensive maintenance strategy that addresses cleaning, airflow management, monitoring, and seasonal considerations, you can unlock the full potential of your air-cooled heat exchangers, ensuring they operate at peak efficiency and reliability for years to come.

Optimization Strategies for Air-Cooled Heat Exchangers

In addition to maintaining optimal performance through regular maintenance, there are several strategies and techniques that can be employed to further enhance the efficiency and capabilities of air-cooled heat exchangers.

Enhancing Heat Transfer Efficiency

Innovations in materials, coatings, and surface geometries can significantly improve the heat transfer efficiency of air-cooled heat exchangers. For example, using high-conductivity materials, such as copper or aluminum, or applying specialized coatings that reduce fouling can enhance the overall heat transfer rate.

Improving Airflow Management

Optimizing the airflow through the heat exchanger can have a significant impact on its performance. This can be achieved through the use of computational fluid dynamics (CFD) analysis to identify and address airflow bottlenecks, as well as the incorporation of advanced fan and duct designs.

Leveraging Hybrid Cooling Systems

In some applications, combining air-cooled heat exchangers with other cooling technologies, such as evaporative or water-cooled systems, can provide a more comprehensive and efficient cooling solution. These hybrid systems can offer improved performance, reduced energy consumption, and enhanced flexibility to accommodate varying cooling demands.

Incorporating Predictive Maintenance

By integrating advanced monitoring and analytics capabilities, air-cooled heat exchangers can be transformed into “smart” systems capable of predicting maintenance needs and potential issues. This proactive approach, known as predictive maintenance, can help minimize downtime, optimize equipment lifespan, and improve overall system reliability.

Exploring Innovative Designs

Researchers and manufacturers are continuously exploring new design concepts and materials to push the boundaries of air-cooled heat exchanger performance. This includes the development of microchannel heat exchangers, which feature small, parallel microchannels to enhance heat transfer, as well as the use of advanced materials like carbon composites and additive manufacturing techniques.

By incorporating these optimization strategies, you can unlock the full potential of your air-cooled heat exchangers, enhancing their efficiency, reliability, and adaptability to meet your evolving cooling requirements.

The Future of Air-Cooled Heat Exchanger Technology

The world of air-cooled heat exchangers is rapidly evolving, with advancements in materials, design, and digital technologies poised to transform the way these critical components operate. As the demand for efficient, sustainable, and intelligent cooling solutions continues to grow, the future of air-cooled heat exchangers holds exciting possibilities.

Improved Efficiency and Sustainability

Driven by the need for more energy-efficient and environmentally-friendly cooling systems, manufacturers are developing air-cooled heat exchangers with enhanced thermal performance and reduced environmental impact. This includes the use of advanced materials, such as high-efficiency coatings and lightweight composites, as well as the integration of renewable energy sources, like solar power, to power the cooling systems.

Intelligent and Predictive Capabilities

The integration of Internet of Things (IoT) technologies and machine learning algorithms is revolutionizing the way air-cooled heat exchangers are monitored and maintained. Smart sensors, data analytics, and predictive maintenance algorithms can enable real-time monitoring, early detection of issues, and proactive maintenance planning, ensuring optimal performance and minimizing downtime.

Modular and Scalable Designs

Flexibility and adaptability will be key features of future air-cooled heat exchanger systems. Modular designs, with the ability to easily add or remove individual components, will allow for scalable solutions that can meet the evolving cooling demands of industrial and commercial applications. This modularity, combined with advancements in control systems, will enable more efficient and responsive cooling capabilities.

Integrated Cooling Solutions

As the demand for comprehensive cooling systems continues to grow, air-cooled heat exchangers will increasingly be integrated with other cooling technologies, such as evaporative cooling and water-based systems. These hybrid solutions will leverage the strengths of different cooling methods to provide highly efficient, reliable, and versatile cooling capabilities tailored to specific application requirements.

The future of air-cooled heat exchanger technology is filled with exciting possibilities. By embracing these advancements and staying at the forefront of innovation, businesses and industries can unlock new levels of efficiency, sustainability, and reliability in their cooling systems, ultimately contributing to a more energy-conscious and technologically-advanced future.

At Air Cooled Heat Exchangers, we are committed to staying at the forefront of these technological developments, providing our clients with the latest insights, solutions, and support to help them navigate the evolving landscape of air-cooled heat exchanger technology. Explore our comprehensive resource library to delve deeper into the future of this essential cooling technology.