The Evolving Landscape of Heat Transfer Engineering

The world runs on heat transfer – from power generation to food processing, efficient and reliable thermal management is critical for countless industries. This is where heat transfer engineering services and solutions come into play, a specialized field dedicated to optimizing heat exchange processes for peak performance.

In the dynamic landscape of industrial operations, issues with heat transfer equipment can arise, leading to underperformance or failures. Seasoned heat transfer engineering experts offer in-depth troubleshooting services to diagnose the root causes, whether it’s fouling, flow inefficiencies, or incorrect sizing, and propose tailored solutions to restore efficiency.

But the role of heat transfer engineering extends far beyond fixing problems. It encompasses a wide spectrum of services, from designing new heat exchangers (HXs) or retrofitting existing ones for optimal thermal performance to analyzing and optimizing entire heat transfer processes. By leveraging cutting-edge design tools and staying at the forefront of technological advancements, these experts ensure that heat transfer systems deliver the highest levels of efficiency and energy savings.

Advancing Heat Exchanger Design and Performance

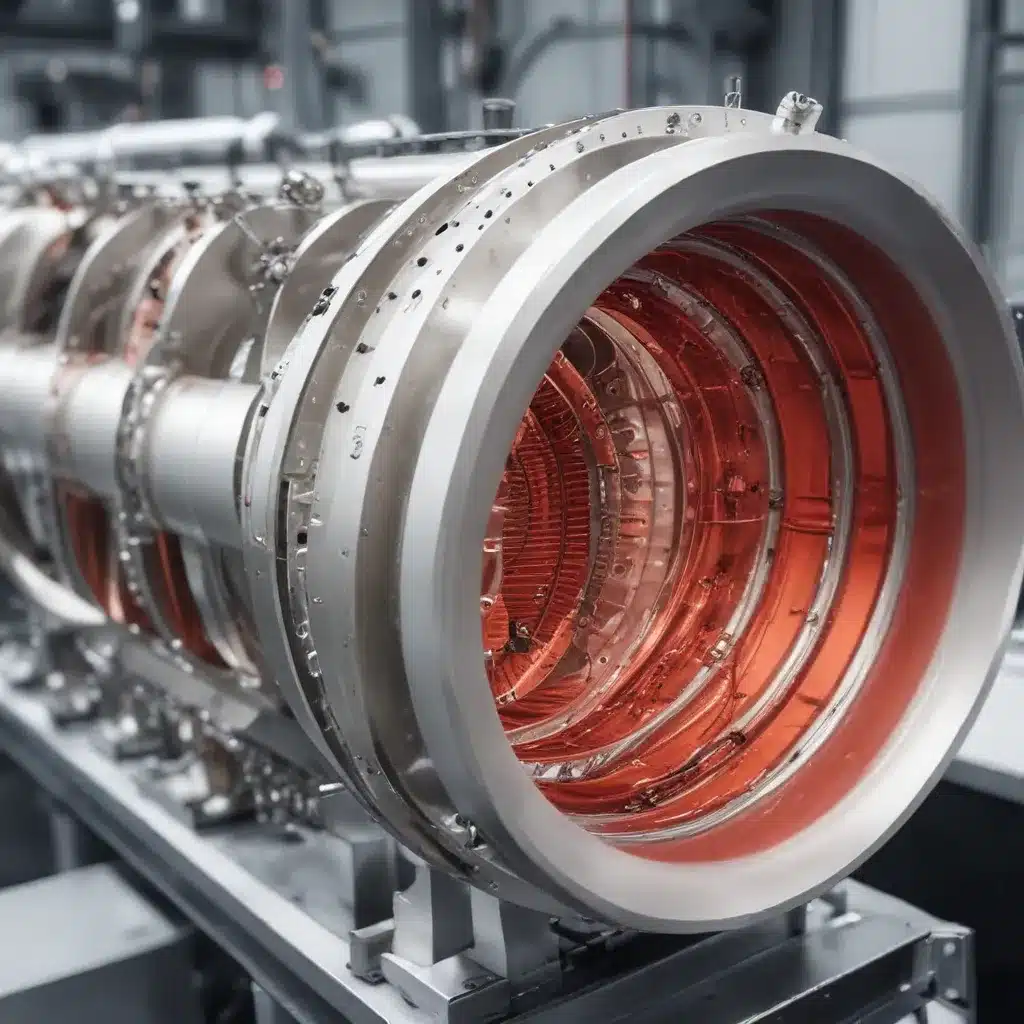

At the core of heat transfer engineering lies the art of designing heat exchangers that efficiently transfer heat between fluids while minimizing energy losses. Whether it’s conceptualizing innovative designs for new installations or revamping existing systems for enhanced performance, meticulous calculations and a deep understanding of thermal dynamics are crucial.

Innovative heat exchanger designs, enabled by the latest advancements in materials, manufacturing techniques, and computational fluid dynamics, are unlocking new levels of thermal efficiency. One such example is the development of counter-flowing fluid heat exchanger designs that boast up to 14 times more surface area compared to traditional designs. This enhanced surface area allows for more efficient heat transfer, leading to improved overall system performance and reduced carbon emissions.

Moreover, the integration of advanced heat transfer materials, such as high-performance ceramics, is enabling the creation of durable and thermally conductive heat exchangers capable of withstanding harsh operating environments. These materials not only enhance the longevity of the equipment but also contribute to improved energy efficiency by minimizing heat losses.

Harnessing the Power of Waste Heat Recovery

Every year, the world consumes vast amounts of energy, primarily by burning fossil fuels and generating heat. Unfortunately, much of this generated heat is unused and released into the environment as “waste heat.” Recovering and repurposing this waste heat presents a significant opportunity to reduce primary energy consumption and greenhouse gas emissions.

Advancements in waste heat recovery technologies have unlocked new possibilities for industrial facilities to capture and reuse this otherwise lost thermal energy. Steam-based waste heat recovery systems, for instance, leverage the exhaust heat from various industrial processes to generate steam, which can then be redirected for use in power generation, heating, or additional manufacturing applications.

By tapping into this vast reservoir of untapped potential, industrial entities can drastically reduce their energy costs and carbon footprint. The integration of cutting-edge heat recovery solutions, such as those employing advanced heat exchangers and steam cycles, has been a game-changer, allowing for the efficient utilization of waste heat across a broader range of temperature ranges, including challenging low-temperature applications.

Optimizing Heat Transfer Processes for Sustainability

As the world moves towards a more sustainable future, the role of heat transfer engineering in supporting environmental stewardship has become increasingly crucial. Leveraging the latest advancements in thermal management, heat transfer experts are now able to design systems that not only enhance energy efficiency but also minimize the impact on the environment.

One such area of focus is the elimination of once-through cooling water systems, which are often energy-intensive and have a significant environmental impact. By facilitating the transition towards closed-loop cooling solutions, heat transfer engineers are helping industrial facilities conserve water resources and reduce their overall environmental footprint.

Furthermore, the integration of green engineering principles into heat transfer system design is rapidly gaining traction. This includes the incorporation of energy-efficient technologies, the selection of environmentally friendly materials, and the optimization of thermal processes to minimize greenhouse gas emissions. As a result, industrial entities are able to achieve their sustainability goals while also reaping the benefits of improved operational efficiency and reduced energy costs.

Empowering Teams through Knowledge Dissemination

Effective heat transfer engineering goes beyond just designing and optimizing systems; it also involves empowering clients with the requisite knowledge and expertise to manage their thermal management challenges. Comprehensive training programs covering general heat transfer concepts, specialized heat exchanger design, and troubleshooting techniques play a crucial role in fostering a deeper understanding within organizations.

By equipping teams with the necessary skills and know-how, heat transfer engineering services ensure that clients can independently maintain and optimize their heat transfer systems, leading to long-term operational resilience and cost savings. This approach not only enhances the overall effectiveness of the solutions but also promotes a culture of continuous learning and innovation within the industry.

Navigating the Complexities of Heat Transfer Engineering

Navigating the ever-evolving landscape of heat transfer engineering requires a strategic and multifaceted approach. Staying at the forefront of technological advancements, maintaining a client-centric mindset, and upholding the highest standards of quality and risk management are just a few of the key strategies that underpin the success of leading heat transfer engineering providers.

By fostering a culture of innovation and adaptability, these experts are able to leverage emerging technologies and methodologies to deliver cutting-edge solutions that address the unique needs and challenges of their clients. Rigorous quality assurance protocols and proactive risk management strategies ensure the integrity and reliability of the heat transfer systems, safeguarding the interests of all stakeholders.

Moreover, the heat transfer engineering field is inherently collaborative, and strategic partnerships with industry stakeholders, academia, and technology providers enable the integration of collective expertise and resources to tackle complex challenges and drive innovation.

Unlocking the Full Potential of Heat Transfer Solutions

As the world increasingly recognizes the critical role of efficient thermal management in industrial operations, the demand for innovative heat transfer engineering solutions continues to grow. By embracing the latest advancements in materials, design tools, and waste heat recovery technologies, heat transfer experts are poised to unlock new levels of efficiency, sustainability, and cost savings for their clients.

Whether it’s designing cutting-edge heat exchangers, optimizing entire heat transfer processes, or facilitating the transition towards greener thermal management practices, these engineering professionals are at the forefront of the industry, driving progress and shaping a more sustainable future.

By partnering with a reputable and experienced heat transfer engineering services provider, industrial entities can gain access to a wealth of expertise and unlock the full potential of their thermal systems. From enhancing energy efficiency to reducing emissions and empowering in-house teams, the benefits of collaborating with heat transfer engineering experts are far-reaching and transformative.

Ready to explore the possibilities of innovative thermal engineering solutions? Reach out to the Air Cooled Heat Exchangers team today and unlock the path to a more efficient, sustainable, and cost-effective future.