The Evolving Landscape of Air-Cooled Heat Exchangers

In today’s rapidly advancing industrial and commercial landscape, air-cooled heat exchangers are playing an increasingly vital role in optimizing energy efficiency and ensuring compliance with evolving regulations. As the world shifts towards a more sustainable future, the need for innovative thermal management solutions has become paramount. This article will delve into the strategies and insights that seasoned experts in the field of air-cooled heat exchangers can leverage to unlock the full potential of these essential components.

Addressing the Challenges of Increasing Heat Loads

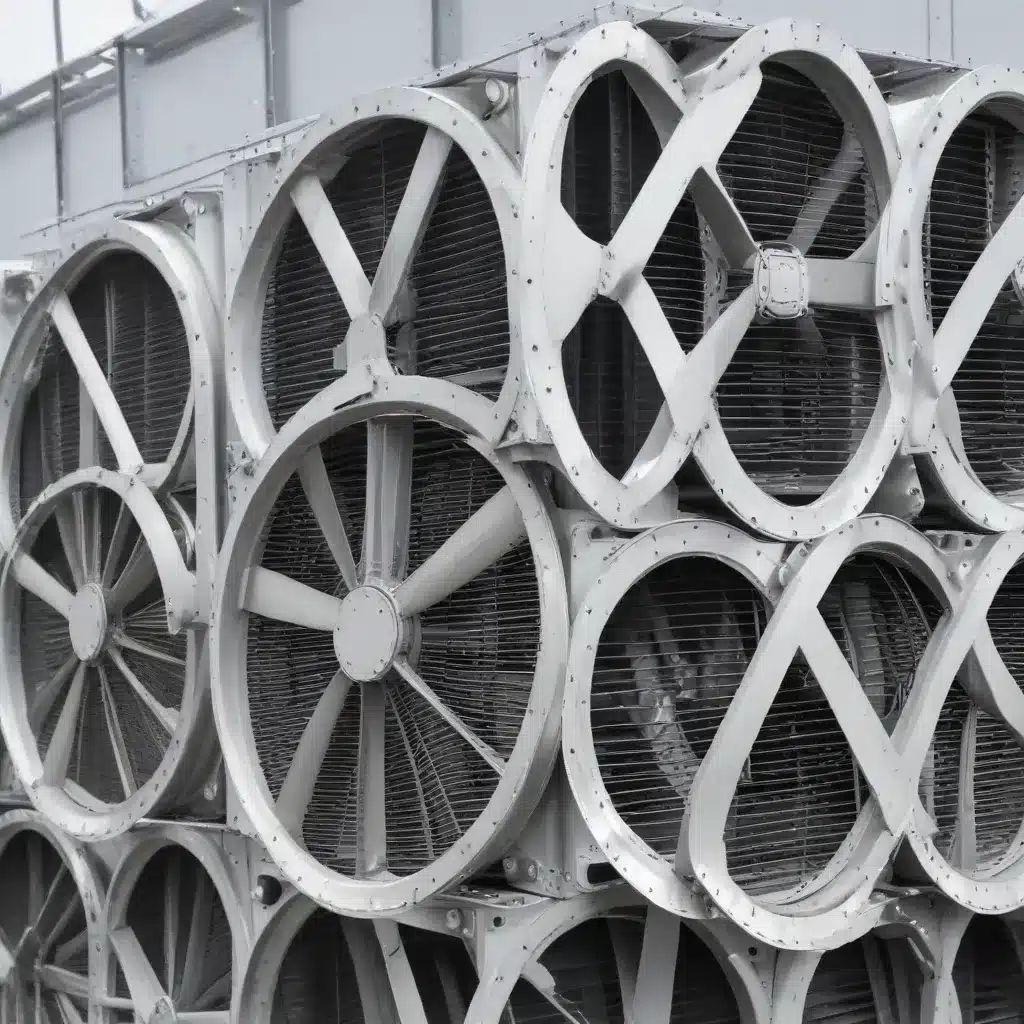

The modern industrial and data center landscape is witnessing a surge in power-dense equipment, generating unprecedented levels of heat. Traditional air-cooling methods are struggling to keep up, as rack power densities exceed the capabilities of conventional approaches. To address this challenge, industry leaders are turning to advanced air-cooled heat exchanger designs that can efficiently dissipate high heat loads.

Key Considerations for High-Density Heat Removal:

- Optimized Fin Geometry: Innovative fin designs, such as louvered or wavy fins, can enhance heat transfer and air-side thermal performance, enabling air-cooled heat exchangers to manage higher heat fluxes.

- Increased Air-Side Surface Area: Incorporating more heat transfer surface area, through the use of densely packed fins or larger heat exchanger sizes, can significantly improve the heat dissipation capacity.

- Enhanced Air-Flow Management: Careful design of air-flow paths and the incorporation of advanced fans or blowers can ensure efficient air movement and heat transfer in high-density environments.

By addressing these critical factors, air-cooled heat exchanger experts can deliver solutions that meet the growing demands of energy-intensive industries and data centers, paving the way for compliance with emerging efficiency regulations.

Navigating the Regulatory Landscape

The global shift towards sustainability has led to the introduction of increasingly stringent energy efficiency regulations for industrial equipment and facilities. Air-cooled heat exchangers, as essential components in a wide range of applications, are under the scrutiny of these evolving standards.

Compliance with Energy Efficiency Mandates

Regulatory bodies, such as the U.S. Department of Energy (DOE) and the European Union’s Ecodesign Directive, have implemented comprehensive energy efficiency requirements for air-cooled heat exchangers. These mandates focus on parameters like minimum efficiency levels, maximum allowable energy consumption, and guidelines for heat exchanger selection and optimization.

Key Regulatory Compliance Considerations:

- Efficiency Metrics: Understanding and adhering to the specific efficiency metrics, such as Coefficient of Performance (COP) or Seasonal Energy Efficiency Ratio (SEER), is crucial for ensuring regulatory compliance.

- Optimization of Component Design: Optimizing the design of individual heat exchanger components, including fins, tubes, and casings, can significantly improve overall system efficiency and meet regulatory thresholds.

- Integrated System Approach: Considering the heat exchanger as part of an integrated system, and optimizing the entire thermal management solution, can further enhance energy efficiency and compliance.

By proactively aligning air-cooled heat exchanger designs with these emerging regulations, industry experts can future-proof their solutions and mitigate the risk of non-compliance, which can lead to costly fines and reputational damage.

Innovative Approaches to Enhance Air-Cooled Heat Exchanger Performance

To stay ahead of the curve and meet the evolving demands of the market, seasoned air-cooled heat exchanger experts are leveraging a range of innovative strategies and technologies. These approaches not only improve energy efficiency but also unlock new levels of performance and reliability.

Integrating Advanced Materials and Coatings

The selection of materials and coatings for air-cooled heat exchangers can have a significant impact on their thermal performance, durability, and energy efficiency. Industry leaders are exploring advanced materials, such as novel alloys and composite structures, to enhance heat transfer, corrosion resistance, and overall system reliability.

Innovative Material and Coating Strategies:

- Enhanced Thermal Conductivity: The use of high-conductivity materials, like copper or aluminum alloys, can improve heat transfer rates and reduce energy consumption.

- Corrosion-Resistant Coatings: Protective coatings that guard against environmental factors, such as salt, chemicals, or UV exposure, can extend the service life of air-cooled heat exchangers.

- Fouling-Resistant Surfaces: Innovative surface treatments that minimize the adhesion of contaminants can improve heat transfer efficiency and reduce maintenance requirements.

By incorporating these advanced materials and coatings, air-cooled heat exchanger experts can deliver solutions that not only meet energy efficiency regulations but also provide long-term reliability and reduced operating costs.

Leveraging Data-Driven Optimization

The rise of Industry 4.0 and the increasing availability of data have empowered air-cooled heat exchanger experts to adopt data-driven approaches for optimizing performance and energy efficiency. By leveraging advanced analytics, machine learning, and digital twin technologies, these experts can gain deeper insights into the behavior and health of their heat exchangers.

Data-Driven Optimization Strategies:

- Performance Monitoring: Deploying sensor-based monitoring systems that track key performance indicators, such as heat transfer rates, pressure drops, and energy consumption, can provide valuable data for optimization.

- Predictive Maintenance: Analyzing historical data and operational patterns can enable predictive maintenance strategies, reducing unplanned downtime and extending the service life of air-cooled heat exchangers.

- Digital Twins: Creating virtual representations of air-cooled heat exchangers can facilitate the testing and optimization of design parameters, leading to enhanced energy efficiency and regulatory compliance.

By embracing these data-driven approaches, air-cooled heat exchanger experts can unlock unprecedented levels of efficiency, reliability, and compliance, positioning their solutions as the preferred choice in the evolving industrial and commercial landscape.

Optimizing Air-Cooled Heat Exchanger Maintenance and Servicing

Maintaining the optimal performance of air-cooled heat exchangers is crucial for ensuring energy efficiency and compliance with regulations. Seasoned experts in this field understand the critical role of proactive maintenance and servicing practices in maximizing the lifespan and efficiency of these essential components.

Preventive Maintenance Strategies

Implementing a comprehensive preventive maintenance program is key to maintaining the peak performance of air-cooled heat exchangers. This includes regular inspections, cleaning, and scheduled replacements of critical components.

Preventive Maintenance Best Practices:

- Periodic Cleaning: Regular cleaning of the heat exchanger surfaces, including fins and tubes, can prevent the buildup of contaminants that can impair heat transfer and efficiency.

- Fin and Tube Inspection: Regularly inspecting the condition of fins and tubes, and addressing any damage or deformation, can help maintain optimal air-flow and heat dissipation.

- Component Replacement: Replacing worn or damaged components, such as fans, motors, or control systems, can ensure continued reliable operation and energy-efficient performance.

By following these preventive maintenance strategies, air-cooled heat exchanger experts can help their clients maintain compliance with energy efficiency regulations while maximizing the long-term performance and lifespan of their equipment.

Embracing Emerging Servicing Technologies

As the industry evolves, air-cooled heat exchanger experts are also exploring innovative servicing technologies to enhance maintenance processes and improve overall efficiency.

Emerging Servicing Technologies:

- Remote Monitoring: Leveraging IoT-enabled sensors and cloud-based platforms to remotely monitor the health and performance of air-cooled heat exchangers can enable proactive maintenance and optimize energy efficiency.

- Augmented Reality (AR) and Robotics: Integrating AR-guided maintenance procedures and robotic servicing tools can improve the accuracy, safety, and speed of maintenance tasks, reducing downtime and energy losses.

- Predictive Analytics: Applying advanced analytics and machine learning to maintenance data can help predict failures, optimize service schedules, and ensure regulatory compliance.

By embracing these emerging servicing technologies, air-cooled heat exchanger experts can deliver more efficient, cost-effective, and compliant maintenance solutions to their clients, further enhancing the overall performance and reliability of these critical components.

Adapting to Evolving Applications and Industries

Air-cooled heat exchangers are essential components across a wide range of industries, from manufacturing and energy production to data centers and HVAC systems. As these industries adapt to new technologies, regulations, and sustainability goals, air-cooled heat exchanger experts must stay ahead of the curve to provide tailored solutions.

Addressing the Needs of the Data Center Industry

The data center industry is undergoing a significant transformation, driven by the exponential growth of cloud computing, artificial intelligence, and edge computing. Air-cooled heat exchangers play a crucial role in managing the heat loads generated by high-performance servers and IT equipment in these facilities.

Data Center Heat Management Considerations:

- High-Density Cooling: Designing air-cooled heat exchangers that can efficiently dissipate heat from high-density rack configurations, with power densities exceeding 50 kW per rack.

- Energy Efficiency: Ensuring air-cooled heat exchanger designs comply with stringent energy efficiency regulations, such as ASHRAE standards and the EU’s Ecodesign Directive.

- Integrated Cooling Solutions: Developing air-cooled heat exchangers that seamlessly integrate with other cooling technologies, such as liquid cooling or two-phase cooling, to optimize the overall data center thermal management system.

By addressing these specialized requirements, air-cooled heat exchanger experts can deliver solutions that enable data centers to meet their growing computational demands while maintaining compliance with energy efficiency regulations.

Adapting to Renewable Energy Integration

As the global economy transitions towards renewable energy sources, air-cooled heat exchangers are playing a vital role in supporting the integration of these technologies. From concentrated solar power plants to geothermal energy systems, air-cooled heat exchangers are essential for managing the thermal energy flows and ensuring efficient energy conversion.

Renewable Energy Integration Considerations:

- Thermal Efficiency: Designing air-cooled heat exchangers with high thermal efficiency to maximize the conversion of renewable thermal energy into electricity or other useful forms of energy.

- Environmental Compatibility: Selecting materials and coatings for air-cooled heat exchangers that can withstand the harsh operating conditions often encountered in renewable energy applications, such as high temperatures, corrosive environments, or extreme weather.

- Scalability: Developing modular and scalable air-cooled heat exchanger solutions that can be easily integrated into renewable energy systems of varying sizes and capacities.

By addressing these unique requirements, air-cooled heat exchanger experts can enable the seamless integration of renewable energy technologies, contributing to the global transition towards a more sustainable energy future.

Conclusion: Unlocking the Full Potential of Air-Cooled Heat Exchangers

As the world grapples with the urgent need for improved energy efficiency and sustainability, air-cooled heat exchangers have emerged as critical components in a wide range of industrial and commercial applications. Seasoned experts in this field possess the knowledge, expertise, and innovative mindset required to unlock the full potential of these essential thermal management solutions.

By addressing the challenges of increasing heat loads, navigating the evolving regulatory landscape, embracing advanced materials and data-driven optimization, and adapting to the needs of diverse industries, air-cooled heat exchanger experts can deliver cutting-edge solutions that not only meet but exceed energy efficiency standards. Through their commitment to continuous improvement and their deep understanding of the latest trends and technologies, these experts are poised to drive the next generation of air-cooled heat exchanger innovation, paving the way for a more sustainable and efficient future.

To learn more about how Air Cooled Heat Exchangers can help your organization unlock the potential of air-cooled heat exchangers and comply with emerging energy efficiency regulations, explore our comprehensive resources or reach out to our team of industry-leading experts.