Understanding the Cryogenic Cooling Challenge

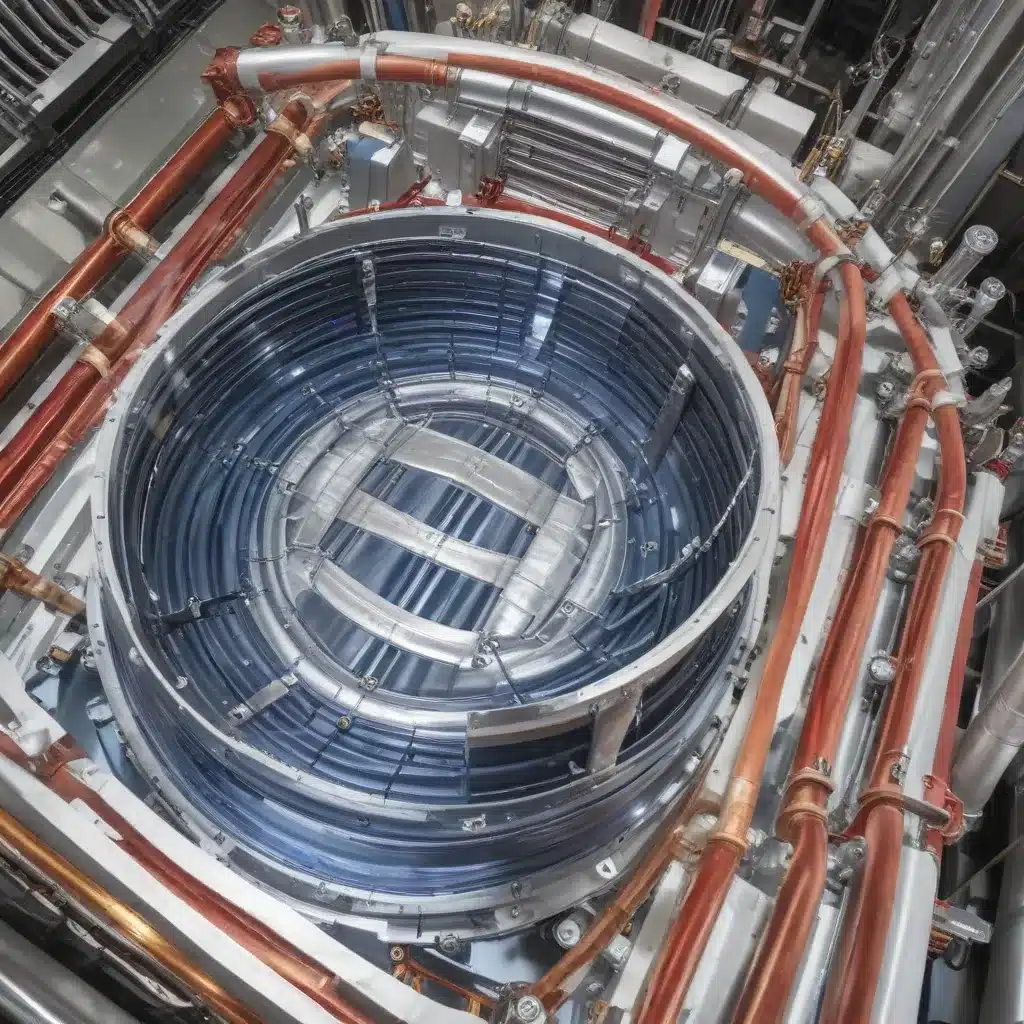

As industries strive to enhance performance while reducing energy consumption, the demand for efficient cooling solutions has become paramount. At the forefront of this pursuit are superconducting technologies, which rely on cryogenic cooling to maintain the precise temperature required for their optimal operation. Among the various cooling approaches, air-cooled heat exchangers have emerged as a viable option, offering several advantages over traditional methods.

Air-cooled heat exchangers leverage the ambient airflow to dissipate the heat generated by superconducting devices, eliminating the need for complex liquid cooling systems. This simplicity translates into improved reliability, reduced maintenance, and a more compact footprint – crucial factors for applications ranging from medical imaging and quantum computing to high-energy physics and space exploration.

However, the effective thermal management of superconducting devices using air-cooled heat exchangers requires a deep understanding of the underlying principles, design considerations, and practical implementation strategies. In this comprehensive article, we will delve into the intricacies of this thermal management approach, providing industry experts and engineering professionals with the insights and practical tips they need to optimize the performance and reliability of their superconducting systems.

Fundamentals of Superconducting Devices and Cryogenic Cooling

Superconducting devices operate at cryogenic temperatures, typically below 20 Kelvin, to achieve their unique properties of zero electrical resistance and the expulsion of magnetic fields. This phenomenon, known as the Meissner effect, is the foundation for numerous applications, including:

- Magnetic Resonance Imaging (MRI): Superconducting magnets in MRI systems require precise temperature control to maintain the necessary field strength for high-resolution medical imaging.

- Quantum Computing: Superconducting qubits, the building blocks of quantum computers, must be cooled to cryogenic temperatures to preserve their delicate quantum states.

- High-Energy Physics: Superconducting magnets in particle accelerators, such as the Large Hadron Collider (LHC), play a crucial role in steering and focusing high-energy particle beams.

- Energy Storage and Power Transmission: Superconducting magnetic energy storage (SMES) systems and power transmission lines leverage the lossless transport of electricity at cryogenic temperatures.

Maintaining these cryogenic temperatures is a significant challenge, as even minor temperature fluctuations can disrupt the superconducting state and compromise the performance of these critical systems. Traditional cooling methods, such as liquid helium or nitrogen-based systems, often require complex and bulky infrastructure, high maintenance, and continuous replenishment of the cryogenic fluid.

The Role of Air-Cooled Heat Exchangers in Cryogenic Cooling

Air-cooled heat exchangers offer a compelling alternative to traditional cryogenic cooling approaches, providing several advantages that make them an attractive choice for a wide range of superconducting applications:

-

Simplicity and Reliability: Air-cooled heat exchangers have a relatively straightforward design, with no moving parts and minimal maintenance requirements. This simplicity translates into improved reliability and reduced operational costs compared to liquid-based cooling systems.

-

Compact Footprint: The absence of cryogenic fluids and the associated storage and delivery infrastructure allows air-cooled heat exchangers to have a much smaller physical footprint, making them well-suited for space-constrained environments like medical equipment or satellite systems.

-

Improved Efficiency: By leveraging the ambient airflow, air-cooled heat exchangers can effectively dissipate heat without the energy-intensive overhead required for pumping and circulating cryogenic liquids.

-

Environmental Sustainability: Air-cooled heat exchangers do not rely on the depletion of limited resources, such as helium, which is a concern with liquid-based cryogenic cooling systems.

-

Versatility: Air-cooled heat exchangers can be designed to accommodate a wide range of cooling capacities and temperature ranges, making them adaptable to diverse superconducting applications.

Despite these advantages, the effective thermal management of superconducting devices using air-cooled heat exchangers requires careful consideration of several key design parameters and operational factors. In the following sections, we will explore these essential elements in detail.

Design Considerations for Air-Cooled Heat Exchangers in Cryogenic Applications

Designing air-cooled heat exchangers for cryogenic cooling applications involves balancing various factors to optimize performance, reliability, and cost-effectiveness. Here are the key considerations:

Heat Transfer Efficiency

The efficiency of the heat transfer process is crucial, as it determines the overall cooling capacity and the ability to maintain the required cryogenic temperatures. Factors such as the heat exchanger’s surface area, fin geometry, and air flow rate must be carefully optimized to maximize the heat transfer rate.

Thermal Insulation

Minimizing heat leaks from the ambient environment is essential to maintain the cryogenic temperatures. Robust thermal insulation, often using materials like vacuum-insulated panels or multilayer insulation (MLI), plays a critical role in reducing conductive, convective, and radiative heat transfer into the cryogenic system.

Airflow Management

Ensuring efficient airflow through the heat exchanger is crucial for effective heat dissipation. The design of the air intake, flow path, and exhaust must account for factors like air velocity, pressure drop, and the potential for air recirculation or stagnation zones.

Cryogenic-Compatible Materials

The materials used in the construction of the air-cooled heat exchanger must be carefully selected to withstand the extreme temperature conditions and prevent thermal contraction issues or material embrittlement at cryogenic temperatures.

Vibration Mitigation

Superconducting devices are often sensitive to mechanical vibrations, which can disrupt their operation. The air-cooled heat exchanger design must include measures to dampen vibrations, such as the use of flexible connections or vibration-isolating mounts.

Integration with Cryogenic Systems

Seamless integration of the air-cooled heat exchanger with the overall cryogenic system is crucial. This includes considerations for the interface with the superconducting device, the control and monitoring systems, and the overall system architecture.

By addressing these design factors, engineers can develop air-cooled heat exchangers that effectively maintain the cryogenic temperatures required for superconducting device operation, while also ensuring reliable, efficient, and cost-effective thermal management.

Practical Considerations for Implementing Air-Cooled Heat Exchangers in Cryogenic Applications

Transitioning from the design phase to the successful implementation of air-cooled heat exchangers in cryogenic applications requires careful consideration of several practical aspects. Let’s explore some of the key considerations:

Site Selection and Airflow Optimization

The location and orientation of the air-cooled heat exchanger can significantly impact its performance. Factors such as ambient temperature, humidity, wind conditions, and potential obstructions must be evaluated to ensure optimal airflow and heat dissipation.

Installation and Commissioning

Proper installation procedures, including the alignment of components, the integrity of thermal insulation, and the integration with the cryogenic system, are crucial to ensure the heat exchanger’s reliable operation from the start.

Maintenance and Servicing

Air-cooled heat exchangers require regular maintenance to maintain their efficiency and prevent issues like air-side fouling or degradation of the thermal insulation. Establishing a proactive maintenance schedule and having access to qualified technicians are essential for long-term system performance.

Monitoring and Control

Implementing robust monitoring and control systems is crucial for the safe and efficient operation of air-cooled heat exchangers in cryogenic applications. This includes monitoring critical parameters such as temperatures, airflow, and vibrations, as well as automated control mechanisms to maintain the desired operating conditions.

Operational Flexibility and Redundancy

Designing for operational flexibility and redundancy can enhance the overall system reliability. This may involve the use of modular or multi-stage heat exchanger configurations, backup cooling systems, or the ability to adjust the cooling capacity to accommodate changing operational requirements.

Troubleshooting and Diagnostics

Establishing effective troubleshooting and diagnostic procedures is essential for quickly identifying and resolving any issues that may arise during the operation of the air-cooled heat exchanger. This includes access to comprehensive documentation, spare parts, and technical support from the manufacturer or specialized service providers.

By addressing these practical considerations, organizations can ensure the successful implementation and long-term reliable performance of air-cooled heat exchangers in their cryogenic applications, maximizing the benefits of this versatile thermal management solution.

Emerging Trends and Future Developments

As the demand for efficient and sustainable cryogenic cooling solutions continues to grow, the field of air-cooled heat exchangers for superconducting applications is witnessing several exciting developments and trends:

-

Advancements in Materials and Manufacturing: Ongoing research into new materials, such as high-performance alloys and advanced ceramics, is enabling the development of air-cooled heat exchangers with enhanced thermal conductivity, reduced weight, and improved resistance to cryogenic temperatures.

-

Integrated Thermal Management Systems: The integration of air-cooled heat exchangers with advanced control systems, sensor networks, and predictive maintenance algorithms is driving the creation of intelligent, self-monitoring, and self-optimizing thermal management solutions.

-

Miniaturization and Modularization: The demand for compact and scalable cryogenic cooling systems, particularly in applications like quantum computing and satellite-based instrumentation, is spurring the development of miniaturized and modular air-cooled heat exchanger designs.

-

Hybrid Cooling Approaches: Researchers are exploring the combination of air-cooled heat exchangers with other cryogenic cooling technologies, such as pulse-tube or Stirling cryocoolers, to create hybrid systems that leverage the strengths of multiple cooling methods.

-

Sustainable and Eco-Friendly Designs: Driven by the need for environmentally conscious solutions, there is a growing emphasis on developing air-cooled heat exchangers that utilize renewable or recyclable materials, minimize energy consumption, and reduce the carbon footprint associated with cryogenic cooling operations.

-

Computational Modeling and Simulation: Advancements in computational fluid dynamics (CFD) and thermal modeling tools are enabling more accurate and efficient design optimization of air-cooled heat exchangers for cryogenic applications, reducing the time and cost of the development process.

-

Collaborative Ecosystems: Partnerships and collaborations between researchers, manufacturers, and end-users are fostering the cross-pollination of ideas and the accelerated development of innovative air-cooled heat exchanger solutions for the cryogenic cooling market.

As these trends continue to shape the landscape of air-cooled heat exchangers for superconducting applications, industry experts and engineering professionals can look forward to even more efficient, reliable, and versatile thermal management solutions that will drive progress in fields ranging from medical diagnostics to quantum computing and beyond.

Conclusion

The effective thermal management of superconducting devices is a critical challenge that requires innovative solutions. Air-cooled heat exchangers have emerged as a compelling alternative to traditional cryogenic cooling methods, offering a range of benefits that make them well-suited for a diverse array of superconducting applications.

By understanding the fundamental principles, design considerations, and practical implementation strategies, industry experts and engineering professionals can leverage the power of air-cooled heat exchangers to optimize the performance, reliability, and sustainability of their superconducting systems. As the field continues to evolve, with advancements in materials, integration, and computational modeling, the future of cryogenic cooling holds exciting possibilities for those who embrace this versatile thermal management technology.

To learn more about the latest developments and practical insights in air-cooled heat exchangers, be sure to visit the Air Cooled Heat Exchangers blog, where industry experts share their knowledge and expertise on a wide range of thermal management topics.