The importance of effective battery cooling

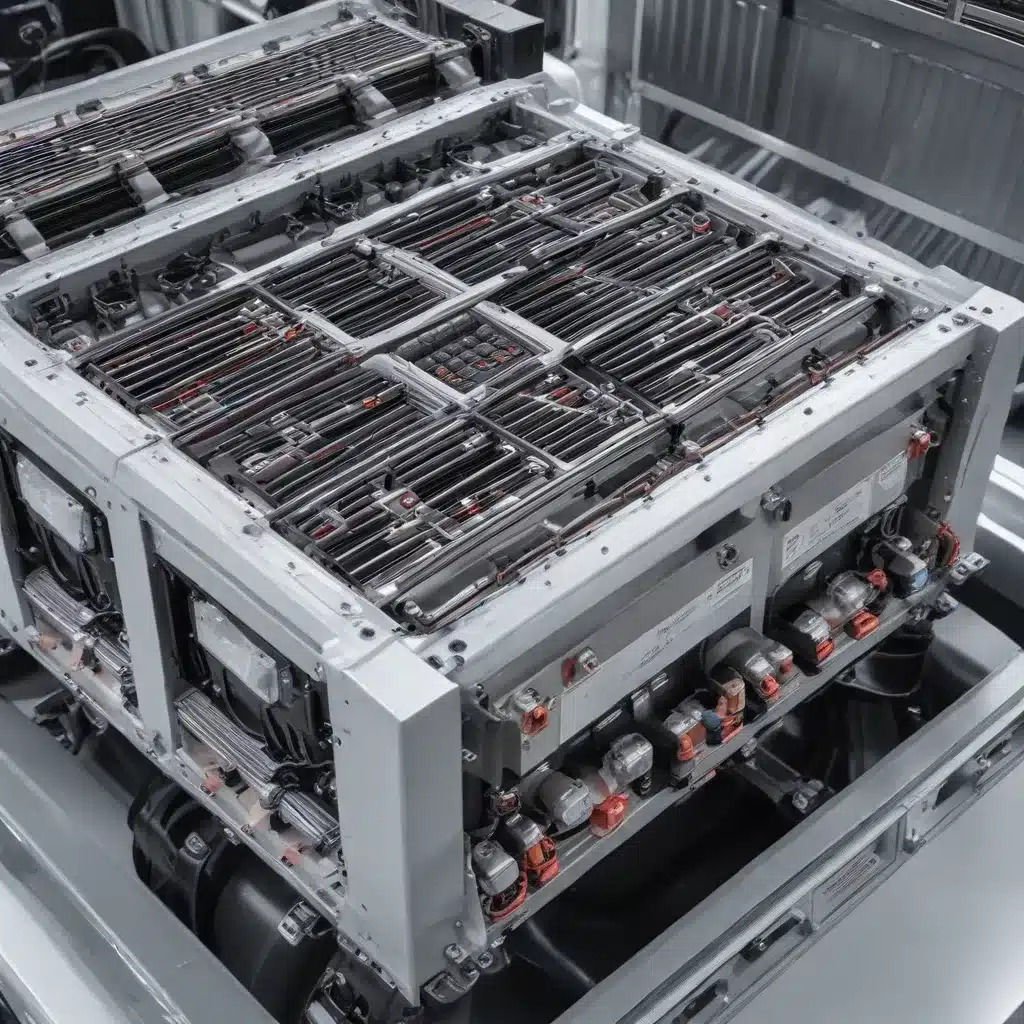

Are you encountering difficulties in effectively managing heat within your electric vehicle (EV) battery systems? Maintaining optimal battery temperatures is crucial for maximizing performance, safety, and longevity, but it can be a daunting challenge. Identifying the right heat exchange solution tailored to your specific battery needs is key.

Exploring the different Battery Thermal Management Systems (BTMS) available on the market is an important first step. Broadly speaking, BTMS can be divided into two categories: active BTMS and passive BTMS. Active systems use external resources like fans or liquid coolers to regulate battery temperature, offering precise control but increased complexity. Passive systems rely on natural heat dissipation methods without external energy input.

Liquid cooling – the preferred solution for EVs

Liquid cooling has emerged as the preferred solution for managing battery temperatures in electric vehicles. This method uses a coolant, usually a mixture of water and glycol, that flows through channels or plates in direct or indirect contact with the battery cells. The heated coolant then passes through a heat exchanger, where the heat is dissipated to the atmosphere, often with a radiator and fan assembly.

Liquid cooling systems can handle much higher heat loads compared to forced air cooling, making them suitable for high-performance applications where rapid heat dissipation is critical. Tesla Model S and BMW i3 are examples of EVs that utilize liquid cooling systems to effectively manage their battery temperatures.

Integrating phase change materials (PCMs) for enhanced cooling

While liquid cooling offers superior heat dissipation capabilities, there is an opportunity to further enhance the thermal management of EV battery systems by integrating phase change materials (PCMs). PCMs absorb and release thermal energy during the process of melting and solidifying at specific temperatures, helping to maintain a stable temperature range.

By combining liquid cooling with integrated PCMs, the advantages of both methods can be leveraged. The PCM absorbs sudden spikes in heat, while the liquid cooling system manages continuous heat removal. This hybrid approach offers optimized performance and efficiency, addressing the diverse thermal challenges faced in EV battery packs.

Customizing liquid cooling solutions for your needs

Every EV battery pack has unique spatial constraints and thermal requirements. Customizing the design of liquid cooling plates and tubes is crucial to effectively meet these specific needs. Options include tailored dimensions, shapes, materials, flow channel designs, connection interfaces, and surface treatments.

Customization allows for better adaptation to various battery layouts, improved thermal conductivity, and enhanced corrosion resistance. For instance, choosing materials like aluminum, copper, or stainless steel can significantly impact the cost-performance ratio of the cooling components.

Surface treatments, such as anodizing or insulating coatings, can further enhance the performance and durability of the liquid cooling system, ensuring compliance with safety standards.

Rapid prototyping for accelerated development

Speed is essential in today’s fast-paced product development cycles. Rapid prototyping services can significantly accelerate the time-to-market for your battery thermal management solutions. By enabling quick design-to-sample capabilities, you can quickly test and validate your customized liquid cooling plates and tubes, supporting your R&D efforts more effectively.

Choosing the right heat exchanger for your project

When selecting the optimal heat exchanger for your EV battery system, consider factors such as your specific thermal needs, the type of battery cells (prismatic, cylindrical, or pouch), and the desired balance between cost and efficiency.

For prismatic battery cooling, plate-type and finned-tube heat exchangers are recommended, as they offer a large heat transfer area and the ability to configure the flow path and resistance to achieve optimal heat transfer efficiency.

The future of battery thermal management

As the demand for high-performance EVs continues to grow, the future of battery thermal management systems looks promising. Upcoming innovations may include the development of new materials with higher thermal conductivity, integration of smart thermal management systems, and advancements in high-voltage cold plates.

These advancements will aim to enhance battery performance while reducing costs and environmental impact, driving the evolution of thermal management solutions to meet the evolving needs of the electric vehicle industry.

Conclusion

Effective thermal management is crucial for optimizing the performance, safety, and longevity of modern EV battery systems. Liquid cooling has emerged as the preferred solution, offering superior heat dissipation capabilities and suitability for compact EV designs.

By integrating phase change materials with liquid cooling systems, you can leverage the advantages of both methods to achieve enhanced thermal regulation and improved overall efficiency. Customizing liquid cooling plates and tubes to your specific needs, as well as leveraging rapid prototyping services, can further optimize the thermal management of your battery system.

Stay informed about the latest developments in battery thermal management technology, as innovations in materials, smart systems, and high-voltage components will continue to drive advancements in this field. With the right thermal management solution, you can unlock the full potential of your EV battery system and ensure reliable, efficient, and sustainable performance.

If you have any questions about battery liquid cooling products or services, feel free to reach out to our team of experts at https://www.aircooledheatexchangers.net/. We’d be happy to assist you in finding the optimal thermal management solution for your electric vehicle battery system.

References

- Thermal modeling of porous medium integrated in PCM and its application in passive thermal management of electric vehicle battery pack

- What are the popular battery heat exchange solutions in the market?

- Thermal modeling of porous medium integrated in PCM and its application in passive thermal management of electric vehicle battery pack