In the ever-evolving world of thermal engineering, air-cooled heat exchangers have emerged as a versatile and efficient solution for a wide range of industries. As technology advances and the demand for sustainable, compact, and high-performance cooling systems grows, understanding the intricacies of air-cooled heat exchanger design, maintenance, and optimization has become increasingly crucial.

Unlocking the Potential of Air-Cooled Heat Exchangers

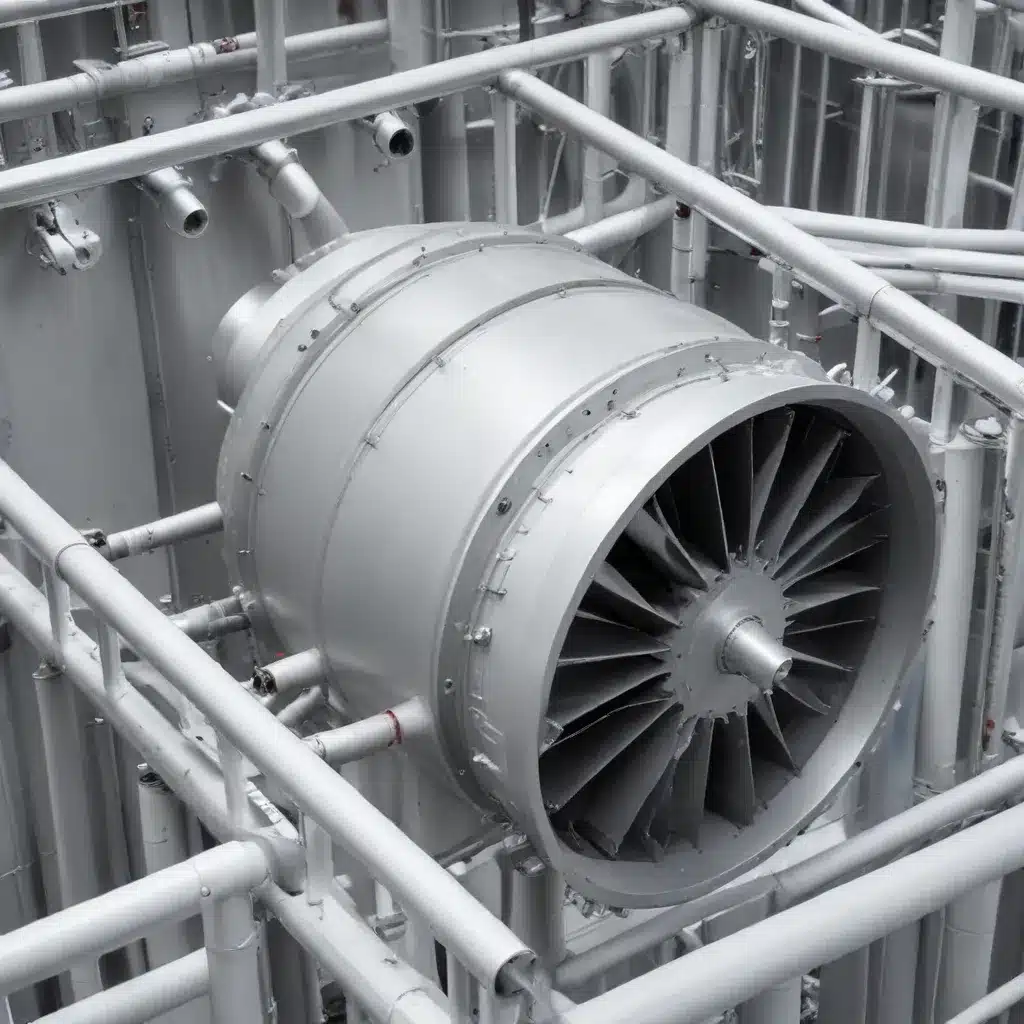

Air-cooled heat exchangers, in contrast to their liquid-cooled counterparts, offer several distinct advantages. They eliminate the need for water or other liquid coolants, reducing the complexity and maintenance requirements of the cooling system. This makes them an attractive choice for applications where space, weight, or environmental constraints are a concern, such as in the automotive, aerospace, and industrial sectors.

One of the key drivers behind the increasing adoption of air-cooled heat exchangers is the advent of high-performance microchannel technologies. As the scale of devices and systems becomes smaller, effective thermal control and heat dissipation become paramount. Microchannel heat exchangers, with their high surface-to-volume ratios, enable enhanced heat transfer rates, making them ideally suited for high-heat-flux applications where space and weight are at a premium.

Advancing the Design Frontier

The design of air-cooled heat exchangers has undergone significant advancements in recent years, driven by the need for improved efficiency, compactness, and reliability. Researchers and engineers have explored various strategies to push the boundaries of air-cooled heat exchanger performance, including:

Innovative Fin Geometries

The design of the heat exchanger fins plays a crucial role in optimizing heat transfer and airflow. Researchers have explored innovative fin geometries, such as wavy, louvered, and offset-strip fins, to enhance the heat transfer coefficient and minimize pressure drop. These intricate fin designs can significantly improve the overall thermal and aerodynamic performance of air-cooled heat exchangers.

Multifunctional Surfaces

The development of multifunctional surfaces has emerged as a promising approach to further enhance the capabilities of air-cooled heat exchangers. These surfaces, which may incorporate features like hydrophobic coatings or micro/nanostructures, can improve heat transfer, reduce fouling, and even enable self-cleaning mechanisms. By tailoring the surface properties, engineers can optimize the heat exchanger’s performance and extend its operational lifespan.

Additive Manufacturing

The advent of additive manufacturing, or 3D printing, has opened up new avenues for air-cooled heat exchanger design. This technology allows for the creation of intricate, customized heat exchanger geometries that were previously challenging or impossible to fabricate using traditional manufacturing methods. Additive manufacturing enables the integration of complex internal flow passages, optimized fin structures, and even embedded sensors, leading to enhanced thermal and structural performance.

Optimizing Air-Cooled Heat Exchanger Performance

Ensuring optimal performance of air-cooled heat exchangers requires a comprehensive understanding of the underlying thermal and fluid dynamics principles, as well as the ability to navigate the nuances of maintenance and troubleshooting.

Thermal-Fluid Analysis

Detailed thermal-fluid analysis, often leveraging computational fluid dynamics (CFD) simulations, plays a crucial role in the design and optimization of air-cooled heat exchangers. These advanced tools enable engineers to model and predict the complex interactions between airflow, heat transfer, and pressure drop, allowing them to fine-tune the heat exchanger geometry and operating parameters for maximum efficiency.

Maintenance and Troubleshooting

Proper maintenance and proactive troubleshooting are essential for ensuring the long-term reliability and performance of air-cooled heat exchangers. Regular inspections, cleaning procedures, and monitoring of key performance indicators can help identify and address issues such as fouling, corrosion, or airflow obstructions before they lead to significant downtime or reduced efficiency.

Optimization Strategies

Optimization strategies, such as the use of machine learning algorithms or multi-objective optimization techniques, can further enhance the performance of air-cooled heat exchangers. These approaches enable engineers to explore a broader design space, identify optimal trade-offs between competing design goals (e.g., heat transfer, pressure drop, and compactness), and develop tailored solutions for specific applications.

Industrial Applications and Emerging Trends

Air-cooled heat exchangers find widespread application across a diverse range of industries, each with its unique thermal management challenges and requirements.

Automotive and Aerospace

In the automotive and aerospace sectors, air-cooled heat exchangers are essential for cooling critical components such as engines, transmissions, and electronic systems. The need for compact, lightweight, and efficient cooling solutions has driven the development of advanced microchannel heat exchangers and innovative fin geometries in these industries.

Power Generation and HVAC

Power generation facilities and heating, ventilation, and air conditioning (HVAC) systems rely on air-cooled heat exchangers to manage the thermal loads associated with equipment cooling, steam condensation, and air conditioning. Advancements in these heat exchangers have contributed to improved energy efficiency and reduced environmental impact in these applications.

Industrial and Chemical Processing

In industrial and chemical processing environments, air-cooled heat exchangers play a vital role in maintaining optimal operating temperatures for a wide range of equipment, such as compressors, reactors, and heat recovery systems. The ability to handle high-temperature applications and withstand corrosive environments has driven the development of specialized materials and coatings for these heat exchangers.

Emerging Trends and Future Outlook

As the demand for sustainable, high-performance cooling solutions continues to grow, several emerging trends are shaping the future of air-cooled heat exchanger technology. These include the integration of renewable energy sources, the adoption of hybrid cooling systems that combine air and liquid cooling, and the incorporation of advanced control and monitoring systems to optimize energy efficiency and reduce operational costs.

Furthermore, the ongoing research and development in areas such as additive manufacturing, multifunctional surfaces, and advanced thermal-fluid modeling are expected to yield even more innovative and efficient air-cooled heat exchanger designs in the years to come. By staying at the forefront of these advancements, engineers and industry professionals can continue to tackle the thermal challenges of today and tomorrow.

Conclusion

Air-cooled heat exchangers have evolved into a critical component in the world of thermal engineering, offering a versatile and efficient solution for a wide range of industries. From the design of innovative fin geometries to the integration of additive manufacturing and multifunctional surfaces, the field of air-cooled heat exchanger technology is constantly pushing the boundaries of performance and efficiency.

By understanding the underlying principles, leveraging the latest design tools and optimization strategies, and prioritizing proper maintenance and troubleshooting, industry professionals can harness the full potential of air-cooled heat exchangers to tackle their most pressing thermal challenges. As the demand for sustainable and high-performance cooling solutions continues to grow, the future of air-cooled heat exchanger technology holds immense promise for revolutionizing the way we manage thermal systems across various industries.

For more information on the latest advancements and best practices in air-cooled heat exchanger design and implementation, be sure to visit https://www.aircooledheatexchangers.net/.