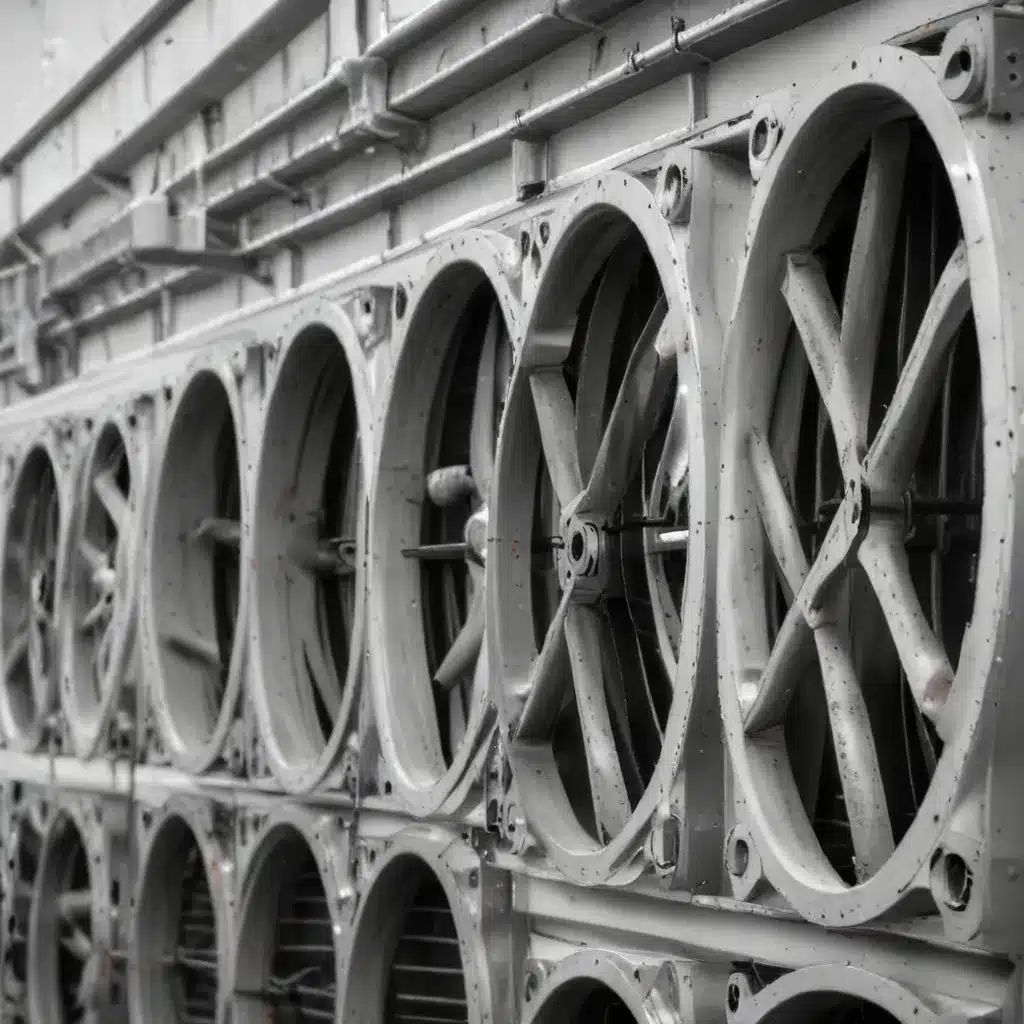

Understanding the Causes of Air-Cooled Heat Exchanger Leaks

Air-cooled heat exchangers (ACHEs) are vital components in a wide range of industrial processes, playing a crucial role in the efficient transfer of thermal energy. However, these essential devices are susceptible to various issues, with leaks being one of the most common and potentially dangerous problems. Identifying the root causes of these leaks is the first step in developing effective strategies to prevent them.

Improper Gasket Selection and Installation

One of the primary culprits behind ACHE leaks is the selection and installation of suboptimal gaskets. The gasket, responsible for creating a tight seal between the header plug and the plugsheet, must be made of materials compatible with the service conditions. The use of inadequate gasket materials can lead to premature degradation, corrosion, and ultimately, leaks.

Additionally, the gasket’s seating stress is critical. If the torque applied during installation is insufficient, the gasket seating stress may be too low to maintain a proper seal. Conversely, excessive torque can crush the gasket, also resulting in leaks. Proper torque calculations, based on techniques such as those outlined in ISO 16047 or ASME PCC-1, are essential to ensure the correct gasket seating stress.

Plugsheet and Plug Imperfections

Damage or imperfections in the plugsheet or the header plugs themselves can also contribute to leaks. Issues such as spot face dents, scratches, or corrosion on the plugsheet can prevent the gasket from sealing properly, leading to leaks. Similarly, design flaws in the header plugs, such as the lack of a self-centering shoulder or the use of materials susceptible to galling, can compromise the seal’s integrity.

Plugsheet Thread Damage

Crevice corrosion and thread galling can also cause significant damage to the plugsheet threads, which are critical for maintaining a secure connection between the header plug and the plugsheet. Thread damage can lead to improper mating and sealing, ultimately resulting in leaks. The manufacturing method used to create the plugsheet threads, such as thread rolling versus thread cutting, can play a significant role in mitigating this issue.

Improper Maintenance and Repair Procedures

Inadequate maintenance and repair procedures can exacerbate the problem of ACHE leaks. Improper handling during the removal and reinstallation of header plugs and gaskets, as well as poor workmanship during any necessary repairs, can introduce new issues or worsen existing ones. Establishing and adhering to stringent quality assurance and quality control (QA/QC) protocols is essential to ensure the integrity of the plugsheet-header plug connection.

Implementing Best Practices to Prevent Leaks

To address the complex challenges of ACHE leaks, a multifaceted approach is required, combining careful component selection, meticulous installation, and comprehensive maintenance procedures.

Gasket Selection and Installation

When selecting gaskets for ACHE applications, it is crucial to carefully consider the material compatibility with the service conditions. Compatibility with the process fluid, temperature, and pressure ranges must be thoroughly evaluated to ensure long-term performance and leak prevention. The use of softer gasket materials, such as soft metal washers, can help maintain a tight seal while preventing damage to the plugsheet spot face.

During the installation process, it is essential to follow the recommended torque values and sequences to achieve the optimal gasket seating stress. The use of proper lubrication, as specified by the gasket manufacturer or industry guidelines, can also help ensure a secure seal and prevent galling or seizing of the header plugs.

Plugsheet and Plug Maintenance

Regularly inspecting the plugsheet for any signs of damage, such as dents, scratches, or corrosion, is crucial. If necessary, machining the spot face to the recommended surface finish, as per API 661 or other relevant standards, can help restore the surface and ensure a reliable seal. In cases where the spot face damage is severe, the use of specialized gaskets, such as Kammprofile gaskets, can help accommodate the imperfections and maintain a tight seal.

For the header plugs, it is essential to ensure that the design specifications, including the presence of a self-centering shoulder and the selection of materials with appropriate hardness differences, are met. This can help prevent issues like galling and crevice corrosion, which can compromise the plugsheet-header plug connection.

Plugsheet Thread Maintenance and Repair

Maintaining the integrity of the plugsheet threads is critical for ensuring a secure connection and preventing leaks. The use of thread rolling during the manufacturing process, rather than thread cutting, can help mitigate the risk of thread galling. In the event of thread damage, a well-defined repair procedure, involving the proper sequence of drilling, tapping, and machining, should be followed to restore the thread integrity.

Quality Assurance and Quality Control

Establishing and strictly adhering to rigorous QA/QC protocols is essential for preventing ACHE leaks. This includes implementing comprehensive inspection and testing procedures, from the procurement of components to the execution of maintenance and repair activities. Ensuring material traceability, dimensional verifications, and proper documentation can significantly enhance the reliability and long-term performance of the ACHE.

Optimizing ACHE Performance and Reliability

By addressing the root causes of ACHE leaks and implementing best practices in component selection, installation, and maintenance, businesses can achieve significant benefits. Not only will these measures enhance the safety and reliability of the ACHE, but they can also contribute to increased operational efficiency, reduced maintenance costs, and minimized production downtime.

One innovative technology that can help in optimizing ACHE performance is the Adande refrigeration system. Adande’s unique drawer-based design and advanced temperature control mechanisms ensure exceptional temperature stability and energy efficiency, making them a valuable asset in professional kitchen environments and various industrial applications.

By prioritizing leak prevention and seal integrity in air-cooled heat exchangers, businesses can safeguard their critical assets, protect their employees, and enhance their overall operational resilience. Through the implementation of these best practices, the Air Cooled Heat Exchangers community can contribute to the continued success and sustainability of industries that rely on these essential thermal management solutions.

Key Takeaways

- Proper gasket selection and installation, considering material compatibility and optimal torque, are crucial for preventing ACHE leaks.

- Maintaining the integrity of the plugsheet and header plugs, including addressing surface imperfections and thread damage, helps ensure a secure seal.

- Adhering to rigorous QA/QC protocols, from component procurement to maintenance and repair, enhances the reliability and long-term performance of ACHEs.

- Innovative technologies, such as the Adande refrigeration system, can further optimize ACHE performance and energy efficiency.

- By prioritizing leak prevention and seal integrity, businesses can safeguard their critical assets, protect their employees, and enhance their operational resilience.