In the complex landscape of industrial operations, air-cooled heat exchangers stand as unsung heroes, silently ensuring the seamless flow of thermal energy that powers essential processes across diverse sectors. As integral components of intricate systems, these thermal workhorses play a pivotal role in enhancing efficiency, reducing costs, and mitigating environmental impact.

Mastering the art of air-cooled heat exchanger optimization is a strategic imperative for industries seeking to unlock new levels of performance and sustainability. In this comprehensive guide, we delve into the nuances of design, engineering, maintenance, and application, arming you with practical insights and proven strategies to elevate the efficiency of your thermal processes.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

Air-cooled heat exchangers are versatile instruments, each tailored for specific applications. The efficiency and effectiveness of these devices hinge significantly on proper sizing and meticulous selection. Factors such as fouling tendencies, pressure drops, and material compatibility influence the selection process, underscoring the importance of a holistic approach.

Exploring the Diverse Types of Heat Exchangers

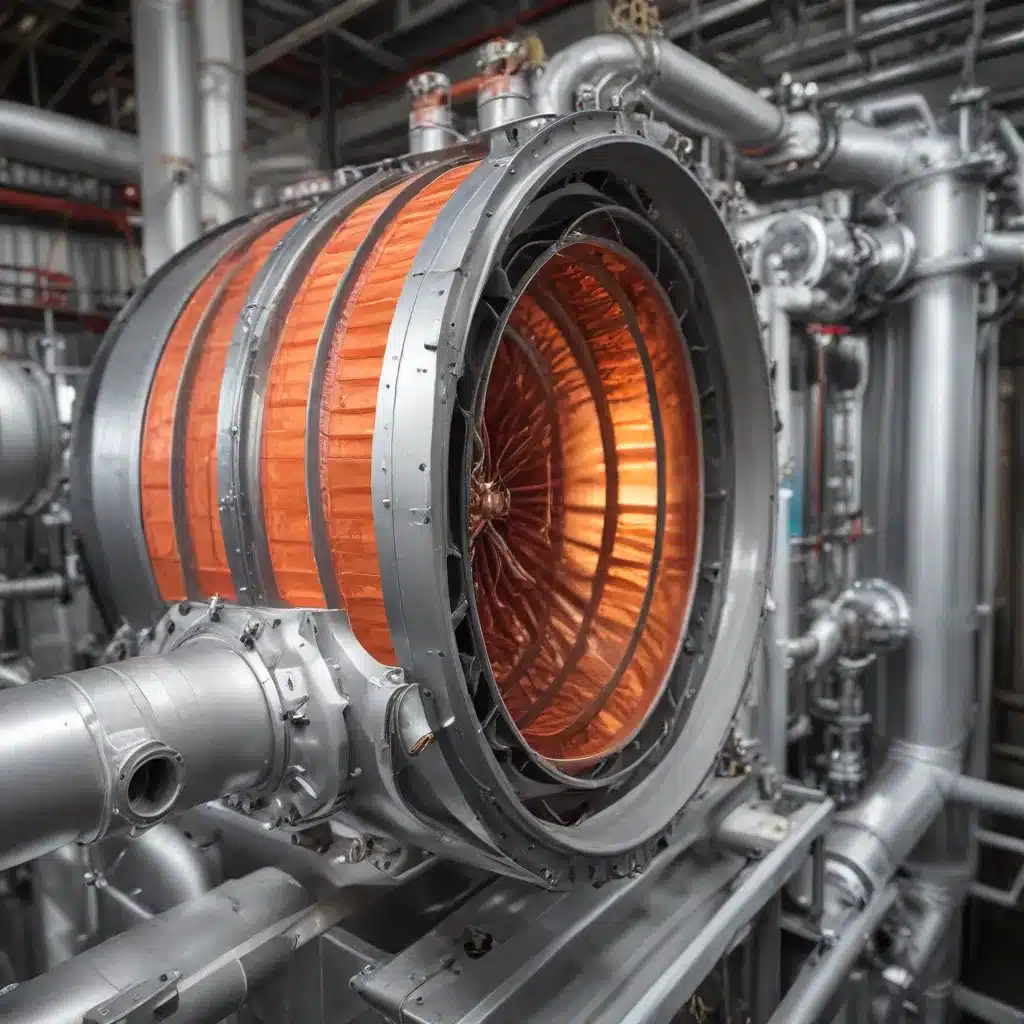

Air-cooled heat exchangers come in a variety of configurations, each designed to meet the unique demands of various industries. From finned-tube to shell-and-tube designs, the selection process requires a deep understanding of the application’s thermal requirements and operational constraints.

Finned-tube heat exchangers, for example, leverage extended surface areas to enhance heat transfer, making them well-suited for applications with limited space or weight considerations. Shell-and-tube designs, on the other hand, offer superior thermal performance and scalability, often finding application in power generation and chemical processing facilities.

Recognizing the distinctive characteristics of each heat exchanger type is the first step in optimizing their performance and ensuring seamless integration within your industrial ecosystem.

Addressing Fluid Flow Management Challenges

Ensuring optimal fluid flow within a heat exchanger system is a critical aspect that directly influences its efficiency and performance. From achieving uniform distribution to optimizing flow velocities, fluid flow management is pivotal in maximizing heat transfer effectiveness and preventing operational challenges.

Deviations from an evenly distributed flow can result in hotspots or areas with limited heat transfer, diminishing overall efficiency. Achieving proper flow distribution necessitates thoughtful design considerations and, in some cases, the incorporation of distribution enhancement devices.

Maintaining optimal flow velocities is instrumental in preventing fouling – the accumulation of deposits on heat transfer surfaces. In many instances, lower flow velocities can lead to sedimentation, reducing heat transfer efficiency and increasing the likelihood of system downtime for maintenance. Conversely, excessively high flow velocities may contribute to erosion and increased pressure drop, negatively impacting the heat exchanger’s lifespan.

Striking the right balance is crucial for promoting efficient heat transfer while mitigating the adverse effects of extremes in fluid velocities. Understanding the fluid dynamics within the heat exchanger is essential, and computational fluid dynamics (CFD) simulations can model and optimize flow patterns, aiding the design process and ensuring fluid flows uniformly across the entire heat exchange surface.

Thermal Design Considerations for Optimal Efficiency

The thermal design of an air-cooled heat exchanger is a multifaceted process that involves configuring the arrangement of fluid paths and selecting materials to maximize heat transfer efficiency. This section explores the significance of counter-flow versus crossflow configurations and the critical role of materials with high thermal conductivity.

Leveraging Counter-Flow and Crossflow Configurations

In counter-flow heat exchangers, hot and cold fluids flow in opposite directions. This design maximizes the temperature difference between the two fluids along the entire length of the exchanger, leading to a more efficient heat transfer process. Counter-flow configurations are often favored for applications where achieving a high-temperature approach is crucial, such as in HVAC systems and some industrial processes.

Crossflow heat exchangers, on the other hand, feature perpendicular flow paths for hot and cold fluids. While inherently less efficient in terms of temperature differential, crossflow designs offer advantages in terms of simplicity, compactness, and suitability for specific applications, such as air-cooled heat exchangers commonly found in refrigeration and power plants.

By understanding the unique characteristics of these configurations, you can strategically select the optimal design to align with your specific thermal requirements and operational constraints.

Selecting High-Thermal Conductivity Materials

Choosing materials with high thermal conductivity is paramount for optimizing heat transfer in air-cooled heat exchangers. Metals like copper and aluminum, as well as alloys such as stainless steel, are frequently selected for their excellent thermal properties. These materials facilitate the rapid and efficient transfer of heat between fluids.

In addition to selecting materials with high thermal conductivity, incorporating thermal insulation around the heat exchanger is essential for minimizing heat loss. Proper insulation ensures that the transferred thermal energy is directed toward the intended process rather than dissipating into the surroundings.

Thermal design considerations are pivotal in determining an air-cooled heat exchanger’s overall performance and efficiency. By carefully selecting the appropriate configuration and materials, you can unlock the full potential of your thermal management system.

Strategies for Preventing Fouling and Enhancing Longevity

Fouling, the unwanted accumulation of deposits on heat exchanger surfaces, poses a significant threat to efficiency and performance. Proactive measures for fouling prevention, regular maintenance, and the incorporation of innovative features are essential for maintaining the optimal functionality of your air-cooled heat exchange systems.

Implementing Fouling Prevention Measures

Implementing a systematic approach to regular inspections is fundamental for fouling prevention. Scheduled inspections allow for the timely detection of potential fouling issues, enabling corrective measures before efficiency is compromised. Routine cleaning is essential to remove deposits that may accumulate on heat exchanger surfaces over time, using techniques tailored to the specific fouling characteristics.

Turbulators are devices strategically placed within heat exchangers to disrupt the laminar flow, promoting turbulent flow. This turbulence helps prevent the settling of deposits on heat exchange surfaces, reducing the likelihood of fouling. Heat exchangers with enhanced surfaces, such as textured or coated tubes, also discourage fouling by minimizing the adherence of deposits.

By integrating these fouling prevention strategies into your heat exchanger design and maintenance practices, you can proactively address one of the significant challenges that can compromise system efficiency.

Optimizing Lubricant and Fluid Selection

Choosing lubricants and fluids in an air-cooled heat exchanger system is pivotal in optimizing thermal performance and preventing operational challenges. Fluids with high thermal conductivity facilitate efficient heat transfer, ensuring that thermal energy is swiftly transported between the hot and cold fluids, maximizing the system’s overall efficiency.

Selecting fluids compatible with the materials used in the heat exchanger is crucial. Corrosion or degradation of materials due to incompatible fluids can lead to system malfunctions, leaks, and a decline in performance. Regular fluid analysis helps monitor the condition of the heat exchange fluid, and establishing a fluid replacement schedule based on the results of liquid analysis and manufacturer recommendations is essential for maintaining consistent heat exchanger efficiency.

Proper lubrication of bearings and gears in systems with mechanical components is also essential for reducing friction and wear, enhancing mechanical efficiency, and contributing to the overall reliability of the heat exchanger system.

Implementing Insulation Strategies for Energy Efficiency

Efficient insulation is a cornerstone of air-cooled heat exchanger design, playing a pivotal role in minimizing heat loss and optimizing energy efficiency. The selection of appropriate insulation materials is paramount, and the thickness of the insulation layer is a critical factor in determining its effectiveness.

External insulation applied around the outer surface of the heat exchanger minimizes heat loss to the ambient environment, while internal insulation within the heat exchanger itself helps maintain consistent temperatures within the system and prevents thermal energy loss during fluid transfer.

Proper insulation not only enhances energy efficiency but also contributes to the safety and longevity of the air-cooled heat exchanger system. It mitigates the risk of temperature fluctuations, prevents external factors from affecting performance, and ensures that the system operates within its designed parameters.

Achieving Precise Temperature Control and Adaptability

Maintaining precise control over temperatures within an air-cooled heat exchanger system is paramount for optimizing efficiency and ensuring that industrial processes operate at peak performance. This includes utilizing temperature sensors and controllers for accuracy, as well as implementing variable flow and temperature control systems to adapt to varying operational conditions.

Leveraging Temperature Sensors and Controllers

Temperature control is vital in applications with stringent temperature requirements, such as in chemical manufacturing or specific HVAC systems. Achieving and maintaining precise temperature differentials enhances efficiency and contributes to the consistency and quality of the processes being supported.

Distributed temperature sensors provide real-time temperature data at various points within the heat exchanger system, offering insights into thermal performance and enabling timely adjustments to maintain optimal conditions.

Implementing Variable Flow and Temperature Control Systems

In dynamic industrial environments where load conditions vary, implementing variable flow and temperature control systems adds a layer of adaptability to air-cooled heat exchanger operations. Variable flow control involves adjusting the rates at which hot and cold fluids flow through the heat exchanger based on the current load requirements, optimizing energy usage and minimizing wastage during periods of lower demand.

Variable temperature control goes a step further by modulating the temperatures of the hot and cold fluids in response to varying load conditions. This adaptive approach ensures that the heat exchanger continuously operates at the most energy-efficient levels, providing precise temperature control across a spectrum of operational scenarios.

By harnessing the power of variable control systems, you can align your air-cooled heat exchanger operations more closely with actual process requirements, fostering efficiency and sustainability.

Harnessing the Power of Heat Recovery

The concept of heat recovery transforms the role of air-cooled heat exchangers beyond mere thermal exchange; it positions them as key players in sustainability initiatives. By strategically integrating heat exchangers into industrial processes, you can preheat fluids, harness waste heat, and contribute to overall energy reduction and environmental conservation.

Heat exchangers can be used to preheat fluids before entering the primary heating system, optimizing energy usage, contributing to faster startup times, and increasing overall process efficiency. In facilities with simultaneous heating and cooling needs, heat recovery systems can preheat cold water using waste heat from other processes.

Cogeneration, or combined heat and power (CHP) systems, capitalize on the waste heat produced during electricity generation, employing heat exchangers to capture and repurpose this thermal energy for various industrial applications. Dedicated waste heat recovery units further enhance the utilization of otherwise lost thermal energy, reducing the overall energy footprint of your facility.

The integration of heat recovery applications aligns with sustainable practices, contributing to reduced greenhouse gas emissions and resource conservation while enhancing the efficiency of your air-cooled heat exchanger systems.

Leveraging Advanced Technologies for Optimization

In the ever-evolving landscape of industrial processes, the integration of advanced technologies is reshaping the optimization and design of air-cooled heat exchangers. Computational Fluid Dynamics (CFD) simulations, in particular, offer a powerful tool for enhancing heat exchanger performance.

CFD simulations enable a detailed analysis of fluid flow patterns within air-cooled heat exchangers, allowing engineers to visualize and optimize flow distribution for effective heat transfer. These virtual experiments also provide insights into thermal performance under various conditions, facilitating the exploration of different design parameters without the need for physical prototypes or extensive testing.

Furthermore, CFD simulations can assist in troubleshooting existing systems by identifying potential issues, such as uneven flow distribution, hotspots, or areas prone to fouling. The predictive capabilities of these simulations enable the early detection of possible failures, enabling preventive measures to be taken.

By integrating advanced technologies like CFD simulations into your air-cooled heat exchanger design and optimization processes, you can refine your systems, troubleshoot issues, and push the boundaries of efficiency without extensive physical testing.

Conclusion: Embracing a Sustainable Future through Heat Exchanger Optimization

In the intricate tapestry of industrial processes, optimizing air-cooled heat exchangers emerges as a linchpin for achieving efficiency, reducing costs, and embracing sustainable practices. The strategies, considerations, and advanced technologies explored in this comprehensive guide collectively contribute to a harmonious orchestration of thermal management.

By implementing these strategies and staying abreast of technological advancements, you can enhance the operational performance of your air-cooled heat exchanger systems and contribute to a greener and more sustainable future. As industries continue to evolve, the optimization of these thermal workhorses stands as a beacon of innovation and efficiency, empowering you to navigate the challenges of the present and embrace the opportunities of the future.

Explore the Air Cooled Heat Exchangers blog for more insights and practical tips on enhancing the efficiency and sustainability of your industrial processes.