The Imperative of Thermal Management in a Technology-Driven World

The demand for robust and efficient devices is constantly increasing across industries, from automotive to aerospace and beyond. As components become smaller and more powerful, effective thermal management has emerged as a critical challenge for engineers. Without proper heat dissipation, these devices would quickly overheat and fail, compromising performance and reliability.

Thermal management systems play a vital role in ensuring optimal device operation and longevity. Whether it’s cooling electronic components in smartphones, maintaining stable temperatures in data centers, or regulating heat in industrial machinery, the ability to control and regulate temperature is essential. Innovations in materials, heat transfer techniques, and advanced cooling systems have become crucial in addressing the ever-evolving thermal management requirements.

Harnessing the Power of Air-Cooled Heat Exchangers

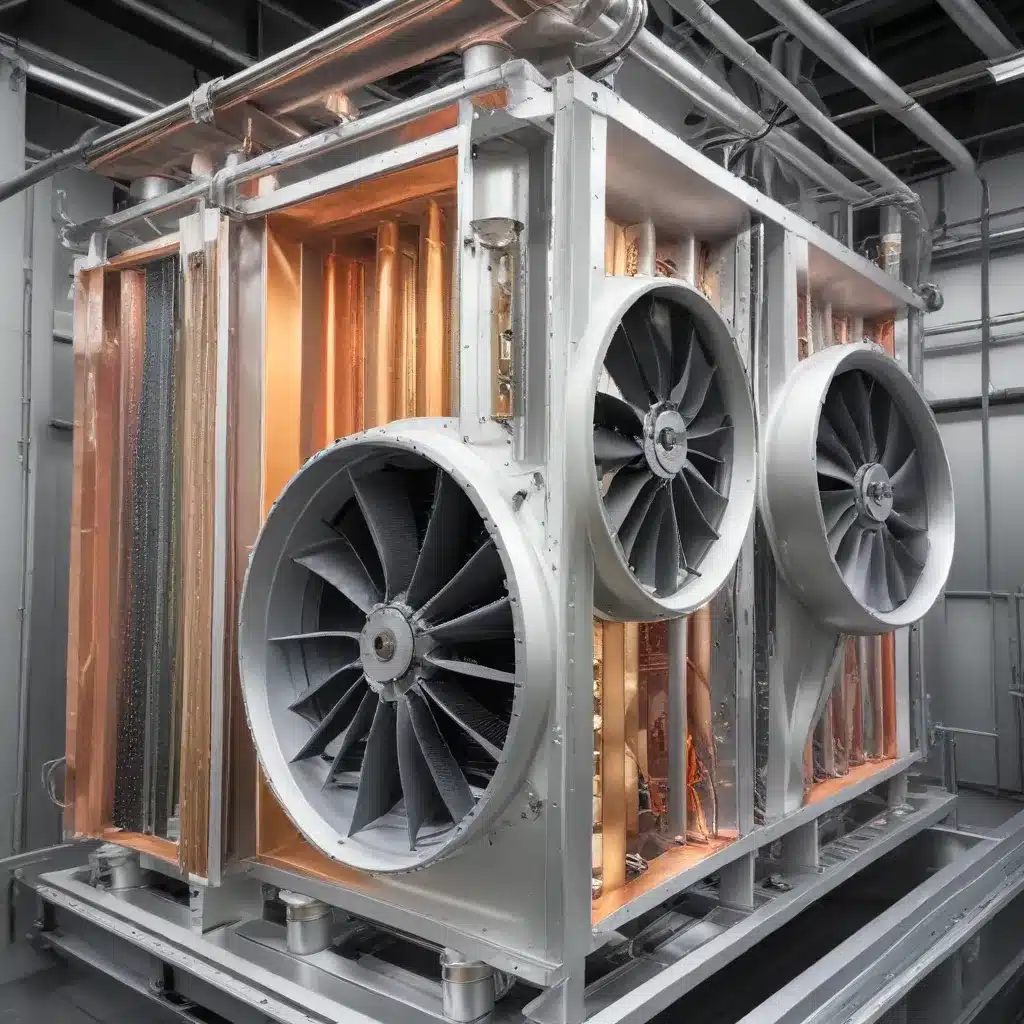

At the heart of many thermal management solutions are air-cooled heat exchangers. These passive cooling devices absorb and dissipate excess heat, acting as a thermal bridge between heat sources and the surrounding environment. Their versatility, cost-effectiveness, and ease of integration make them a popular choice across a wide range of industries, from electronics and automotive to power generation and HVAC systems.

However, as device power densities and operational demands continue to rise, the design and engineering of air-cooled heat exchangers have become increasingly complex. Engineers must navigate a myriad of challenges, such as dissipating higher heat loads within limited spaces, maintaining optimal operating temperatures for sensitive components, and ensuring efficient heat transfer while minimizing pressure drops.

Innovative Approaches to Air-Cooled Heat Exchanger Design

To meet these growing challenges, engineers are exploring and implementing a range of innovative approaches to air-cooled heat exchanger design. These strategies leverage advanced materials, enhanced heat transfer techniques, and sophisticated cooling systems to push the boundaries of thermal management.

Harnessing the Power of Additive Manufacturing

One of the most exciting developments in air-cooled heat exchanger design is the use of additive manufacturing (AM), or 3D printing, technologies. AM offers unparalleled design freedom, allowing engineers to create complex, optimized geometries that are simply not possible with traditional manufacturing methods.

By leveraging the capabilities of AM, designers can:

- Maximize Heat Transfer Surfaces: AM enables the creation of intricate lattice structures and microchannels within the heat exchanger core, significantly increasing the available surface area for heat transfer.

- Enhance Heat Transfer Efficiency: Optimized internal geometries, such as Triply Periodic Minimal Surfaces (TPMS), can improve the fluid flow patterns and heat dissipation within the heat exchanger.

- Improve Compactness and Lightweight Design: AM allows for the integration of complex features and the consolidation of multiple components, resulting in more compact and lightweight heat exchanger designs.

- Adapt to Irregular Spaces: The design freedom of AM enables heat exchangers to be tailored to fit within unique, irregular spaces, optimizing their integration into various systems and applications.

Leveraging Computational Fluid Dynamics (CFD) and Thermal Simulation

The design and optimization of air-cooled heat exchangers have greatly benefited from advancements in computational fluid dynamics (CFD) and thermal simulation tools. These powerful techniques allow engineers to:

- Predict Thermal Behavior: CFD simulations can accurately model the fluid flow and heat transfer characteristics within the heat exchanger, enabling the prediction of temperature distributions, pressure drops, and overall thermal performance.

- Optimize Designs: By integrating CFD and thermal simulation into the design process, engineers can explore a wide range of design iterations, evaluate their impact on thermal performance, and identify the most efficient configurations.

- Reduce Prototyping and Testing: Simulation-driven design approaches can significantly reduce the need for physical prototyping and testing, saving time and resources while accelerating the development of innovative heat exchanger solutions.

Integrating Advanced Cooling Techniques

Beyond the core heat exchanger design, engineers are also incorporating advanced cooling techniques to enhance thermal management capabilities. These include:

- Hybrid Cooling Systems: Combining air-cooled heat exchangers with liquid cooling components, such as heat pipes or cold plates, can provide superior heat dissipation for high-power applications.

- Forced Convection: Integrating fans or blowers with air-cooled heat exchangers can significantly improve heat transfer rates, particularly in scenarios with limited natural convection.

- Intelligent Thermal Management: Leveraging sensors, control systems, and algorithms to actively monitor and regulate the cooling process, ensuring optimal performance and efficiency.

Harnessing the Power of Artificial Intelligence (AI) and Machine Learning (ML)

The rise of AI and ML has opened up new frontiers in the optimization of air-cooled heat exchanger designs. By integrating these technologies, engineers can:

- Analyze Large Datasets: AI and ML algorithms can process vast amounts of data related to heat dissipation, temperature profiles, and system performance, uncovering valuable insights and patterns.

- Predict Thermal Behavior: AI-powered predictive models can forecast the thermal performance of heat exchangers under various operating conditions, enabling proactive design adjustments.

- Automate Optimization: AI-driven optimization algorithms can explore the design space, identify the most promising configurations, and automatically generate optimized heat exchanger geometries.

Applying Innovative Thermal Management Solutions Across Industries

The benefits of these innovative air-cooled heat exchanger design approaches extend across a wide range of industries, each with its unique thermal management challenges and requirements.

Electronics and Semiconductor Cooling

In the fast-paced world of electronics and semiconductors, thermal management is crucial for ensuring the reliability and performance of devices. Air-cooled heat exchangers play a vital role in dissipating the heat generated by high-power components, such as CPUs, GPUs, and power electronics. By leveraging additive manufacturing and advanced cooling techniques, engineers can develop more compact, efficient, and reliable cooling solutions for a wide range of electronic applications, from consumer electronics to data centers.

Automotive and Transportation

Thermal management is a critical consideration in the automotive and transportation industries, where heat generated by engines, power electronics, and other components must be effectively dissipated. Air-cooled heat exchangers are widely used in applications such as engine oil coolers, transmission coolers, and battery thermal management systems. Innovative design approaches, including the use of CFD simulations and hybrid cooling solutions, help engineers optimize heat transfer, reduce weight, and improve overall system efficiency in vehicles.

Aerospace and Defense

In the aerospace and defense sectors, where weight, size, and reliability are of the utmost importance, air-cooled heat exchangers face unique challenges. Designers must balance the need for effective heat dissipation with the constraints of limited space and strict weight requirements. Additive manufacturing and advanced cooling techniques, such as the integration of heat pipes and phase change materials, enable the development of high-performance, lightweight heat exchangers that can withstand the rigors of aerospace and defense applications.

Power Generation and Industrial Machinery

The power generation and industrial machinery industries rely heavily on efficient thermal management to ensure the reliable and optimal operation of their equipment. Air-cooled heat exchangers play a crucial role in cooling generators, turbines, compressors, and other energy-intensive components. By incorporating innovative design approaches, including the use of AI-driven optimization and intelligent control systems, engineers can enhance the thermal performance, energy efficiency, and overall reliability of these critical industrial systems.

Unlocking the Future of Thermal Management with Air-Cooled Heat Exchangers

As technology continues to push the boundaries of what is possible, the need for effective thermal management solutions has never been more pressing. Air-cooled heat exchangers, with their versatility and cost-effectiveness, remain a cornerstone of thermal management in a wide range of industries.

By embracing innovative design approaches, leveraging the power of additive manufacturing, advanced simulation, and AI-driven optimization, engineers are redefining the capabilities of air-cooled heat exchangers. These groundbreaking solutions are enabling the development of more efficient, compact, and reliable thermal management systems that can meet the ever-evolving demands of our technology-driven world.

As we push the limits of what is possible in thermal management, the future holds immense possibilities for air-cooled heat exchangers to play a crucial role in powering the next generation of high-performance, energy-efficient, and sustainable products and systems. The https://www.aircooledheatexchangers.net/ team is at the forefront of this exciting journey, continuously exploring innovative solutions to optimize thermal management and drive the future of engineering innovation.