As a seasoned expert in air-cooled heat exchangers, I’m excited to share insights into the latest advancements in cooling technologies that can help you optimize the efficiency of your heat exchanger systems. In this comprehensive article, we’ll dive deep into practical tips, in-depth analysis, and industry-leading strategies to enhance the performance and sustainability of your heat transfer operations.

Evolving Cooling Demands in Modern Industrial Landscapes

The industrial landscape is rapidly evolving, with increasing demands for more efficient and environmentally-friendly cooling solutions. Traditional air-based cooling systems have proven to be energy-intensive and struggle to keep up with the growing heat loads generated by modern equipment and processes.

As industries strive to reduce their carbon footprint and operational costs, the need for innovative cooling technologies has become paramount. Fortunately, the field of heat exchanger design and engineering has seen remarkable advancements in recent years, offering a wealth of opportunities to optimize efficiency and drive sustainable operations.

Liquid Immersion Cooling: A Transformative Approach

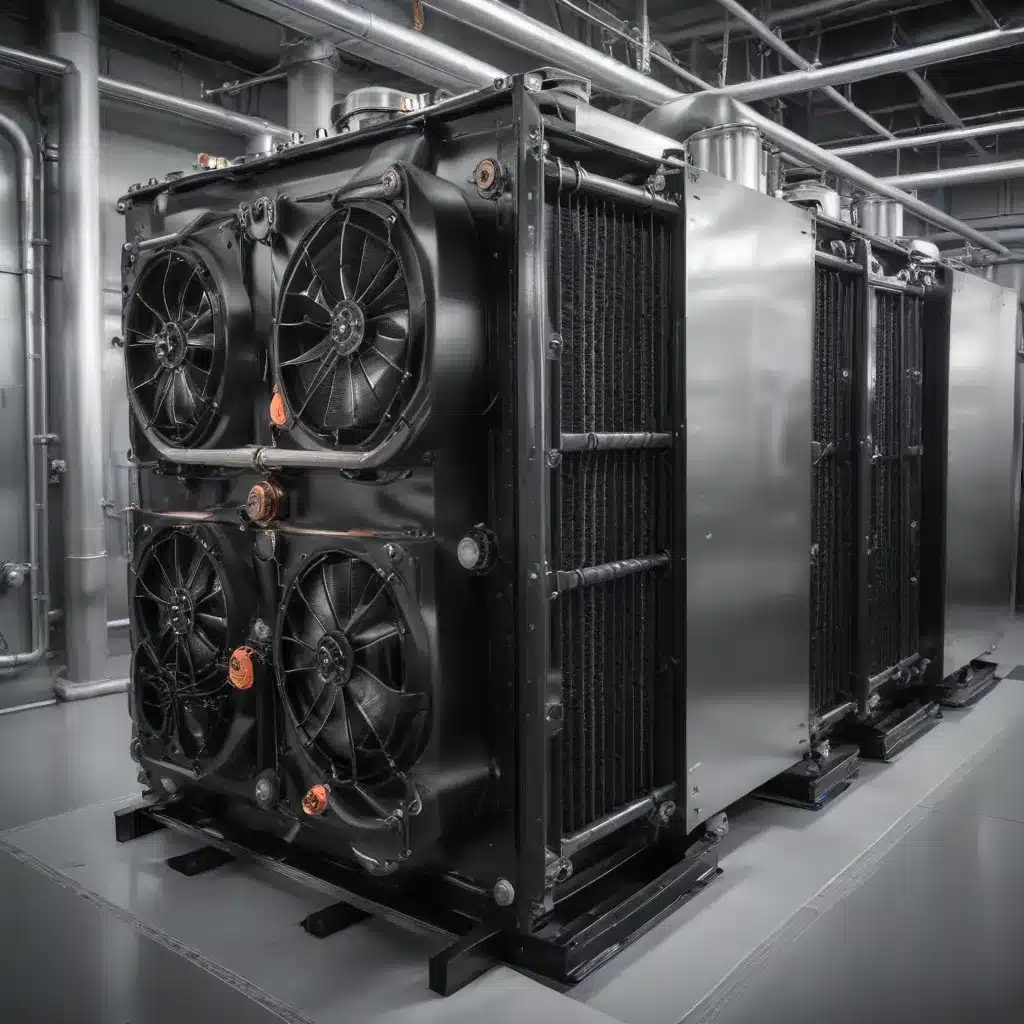

One of the most exciting developments in the world of heat exchangers is the rise of liquid immersion cooling. This revolutionary technique involves submerging computing hardware or heat-generating equipment directly into a specialized, thermally conductive liquid. This fluid efficiently absorbs and dissipates the heat, providing several significant advantages over traditional air-based cooling.

Liquid immersion cooling can reduce energy consumption by up to 95% and water usage by 90% compared to conventional air conditioning systems. The cooling liquid provides excellent insulation, reducing the need for additional infrastructure and resulting in a more compact and efficient cooling system.

As this technology continues to mature, liquid immersion cooling is becoming an increasingly popular choice for sustainable industrial operations. By leveraging the superior heat transfer capabilities of liquids, companies can achieve remarkable improvements in energy efficiency and operational cost savings.

Direct-to-Chip Cooling: Targeted Heat Dissipation

Another innovative approach to heat exchanger optimization is direct-to-chip cooling. This targeted cooling method focuses on the specific components that generate the most heat, such as computer chips and critical industrial equipment. Rather than cooling an entire server, rack, or unit, direct-to-chip cooling delivers coolant directly to the hottest parts of the system.

This approach eliminates the need for bulky heat sinks and fans, leading to more compact and streamlined designs. By addressing the heat load at the source, direct-to-chip cooling can significantly improve overall performance and energy efficiency.

As computing power and industrial automation continue to increase, direct-to-chip cooling is becoming an essential solution for managing the escalating heat loads in modern facilities. By implementing this targeted cooling strategy, organizations can optimize their heat exchanger systems and ensure reliable, high-performance operations.

Hybrid Cooling Systems: Integrating the Best of Both Worlds

While liquid immersion and direct-to-chip cooling offer impressive advancements, some industrial applications may require a more versatile and scalable cooling approach. This is where hybrid cooling systems come into play, combining the benefits of liquid and air-based cooling techniques.

Hybrid cooling systems allow for the effective management of heat loads by leveraging the superior heat transfer capabilities of liquids alongside the flexibility and simplicity of air-based systems. This approach is particularly valuable in environments with varying cooling demands, such as those found in business analytics, military intelligence, and other data-intensive industries.

By integrating both liquid and air cooling methods, hybrid systems enable operators to effectively balance performance, cost, and energy consumption. This scalable solution supports current infrastructure while accommodating future technological advancements and operational growth.

Evaporative Cooling: Harnessing the Power of Evaporation

In addition to the emerging liquid-based cooling technologies, the industry is also exploring innovative air-based cooling solutions, such as evaporative cooling. This method utilizes the natural process of evaporation to remove heat from the air, resulting in significant energy savings compared to traditional air conditioning.

Evaporative cooling systems pull in hot, dry air and pass it over water-soaked pads. As the water evaporates, it cools the air, providing a highly efficient cooling solution. This approach can reduce energy consumption by up to 80% compared to traditional air conditioning.

While evaporative cooling has some limitations, such as the need for additional water supply, the technology continues to advance. Many industrial facilities are now exploring ways to integrate evaporative cooling systems to improve their overall energy efficiency and sustainability.

Thermal Energy Storage: Balancing the Cooling Load

Another innovative cooling technique gaining traction in the industry is thermal energy storage. This approach involves storing thermal energy, typically during off-peak hours, and then using that stored energy to power cooling systems during periods of high demand.

By balancing the cooling load, thermal energy storage can lead to significant energy and cost savings for industrial facilities. The stored thermal energy can be used to chill water or other fluids, which are then circulated through the cooling infrastructure.

As technology advances, thermal energy storage systems are becoming more efficient and cost-effective, making them an increasingly attractive option for organizations seeking to optimize their energy usage and reduce their environmental impact.

Waste Heat Recovery: Maximizing Efficiency through Circularity

Industrial operations often generate substantial amounts of waste heat as a byproduct of their processes. Innovative waste heat recovery systems can capture and repurpose this heat for other useful applications, creating a more circular and sustainable approach to cooling.

By integrating waste heat recovery, industrial facilities can minimize their reliance on external energy sources and create a more self-sufficient cooling and power system. The recovered heat can be used for heating, cooling, or even electricity generation, further enhancing the overall efficiency of the operation.

As technology continues to advance, waste heat recovery is becoming an increasingly valuable tool for energy-efficient industrial operations. By embracing this circular approach, organizations can reduce their environmental footprint, lower operational costs, and contribute to a more sustainable future.

Empowering Efficiency through Monitoring and Analytics

Alongside the advancements in cooling technologies, the importance of energy monitoring and analytics cannot be overstated. Effective energy management is crucial for optimizing the efficiency of heat exchanger systems and driving sustainable operations.

Industrial facilities should adopt comprehensive energy and sustainability monitoring tools that enable real-time data tracking, analysis, and reporting. These tools provide invaluable insights into energy usage patterns, equipment performance, and opportunities for optimization.

By closely monitoring energy consumption across different areas, such as procurement, finance, and even cybersecurity, organizations can make informed decisions to lower energy use, cut costs, and reduce their environmental impact. This holistic approach to energy management is essential for achieving long-term efficiency and sustainability goals.

Conclusion: Embracing the Future of Heat Exchanger Optimization

As the industrial landscape continues to evolve, the demand for efficient and sustainable cooling solutions has become paramount. The advancements in liquid immersion cooling, direct-to-chip cooling, hybrid systems, evaporative cooling, thermal energy storage, and waste heat recovery offer a wealth of opportunities to optimize the performance and efficiency of air-cooled heat exchangers.

By embracing these innovative cooling technologies and implementing robust energy monitoring and analytics, industrial facilities can significantly reduce their energy consumption, operational costs, and environmental impact. As we move towards a more sustainable future, these advanced cooling techniques will play a crucial role in empowering organizations to thrive in the face of escalating heat loads and growing energy demands.

To learn more about how https://www.aircooledheatexchangers.net/ can help you optimize the efficiency of your heat exchanger systems, explore our comprehensive resources and connect with our team of industry experts.