The Importance of Efficient Heat Transfer in Pulp and Paper Production

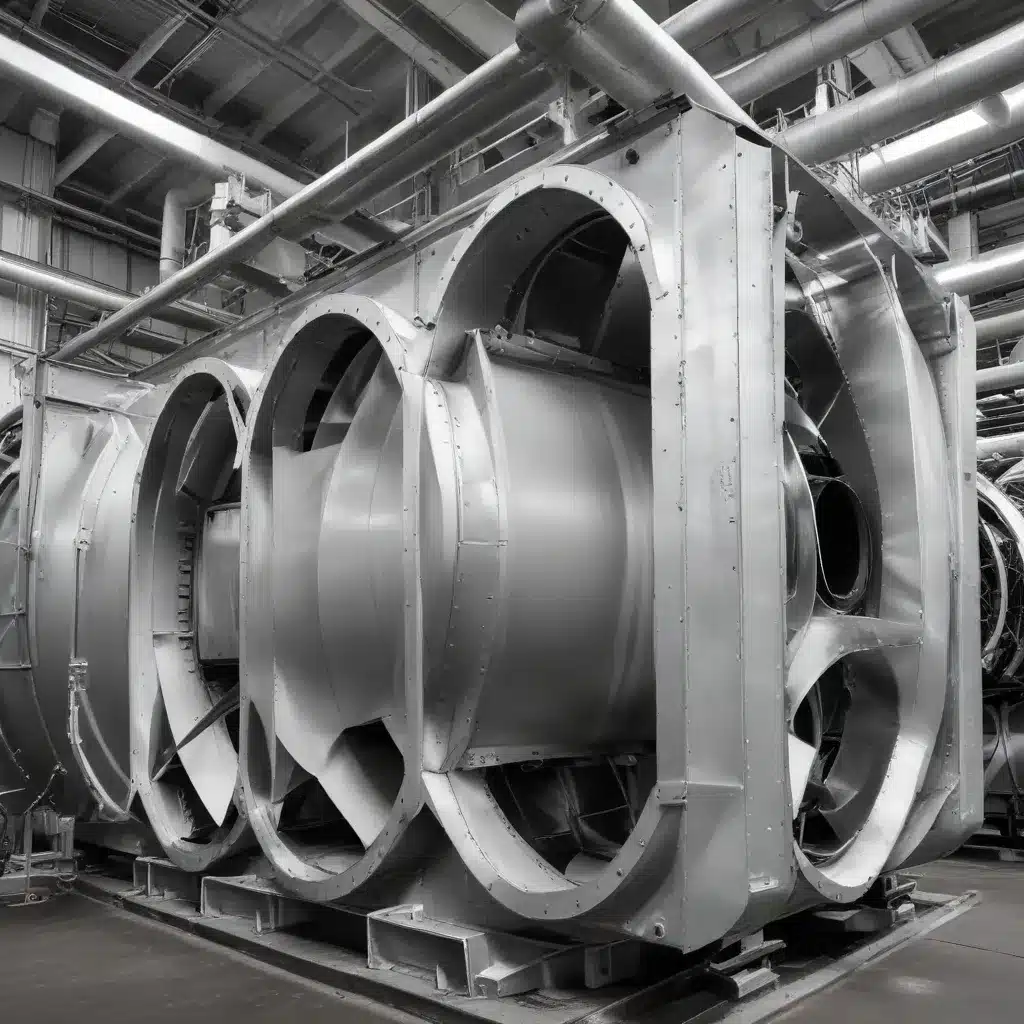

The pulp and paper manufacturing industry is a cornerstone of modern industrial operations, playing a vital role in supporting various sectors with essential materials. From the production of containerboard and tissue products to the manufacture of specialty papers, the industry relies heavily on efficient thermal management to ensure optimal process conditions, product quality, and energy conservation. At the heart of these thermal management systems are air-cooled heat exchangers, specialized devices designed to facilitate the transfer of heat between fluids without direct mixing.

In the pulp and paper industry, air-cooled heat exchangers serve a multitude of critical functions, from cooling process streams and lubricating oils to providing temperature regulation for drying and curing operations. Maintaining the peak performance of these heat exchangers is, therefore, paramount to the overall efficiency, productivity, and sustainability of pulp and paper manufacturing facilities. As an experienced expert in the field of air-cooled heat exchangers, I will provide practical insights and in-depth guidance on optimizing their performance to address the unique thermal management challenges faced by the pulp and paper industry.

Understanding the Role of Air-Cooled Heat Exchangers in Pulp and Paper Production

Air-cooled heat exchangers play a pivotal role in the pulp and paper manufacturing process, contributing to various aspects of thermal management. These robust devices are designed to efficiently transfer heat from one fluid (such as a process stream or coolant) to another, typically air, without allowing the two fluids to mix. This heat transfer process is essential for:

-

Cooling Process Streams: In pulp and paper mills, various process streams, including pulp suspensions, chemical solutions, and steam condensate, require cooling to maintain optimal temperatures for efficient and consistent processing. Air-cooled heat exchangers are strategically placed throughout the facility to facilitate this crucial cooling function.

-

Lubricating Oil Cooling: The machinery used in pulp and paper production, such as pumps, compressors, and gearboxes, require effective cooling of their lubricating oils to prevent overheating and premature wear. Air-cooled heat exchangers are often employed to maintain the optimal operating temperature of these critical lubrication systems.

-

Drying and Curing Processes: Many pulp and paper manufacturing steps, such as drying of paper or curing of coatings, rely on precise temperature control to ensure product quality and consistency. Air-cooled heat exchangers play a vital role in regulating the temperature of the air used in these drying and curing operations.

-

Waste Heat Recovery: Pulp and paper mills often generate significant amounts of waste heat from various processes, such as steam generation or exhausts from dryers. Air-cooled heat exchangers can be employed to capture and repurpose this waste heat, improving the overall energy efficiency of the facility.

By optimizing the performance of air-cooled heat exchangers in these critical applications, pulp and paper manufacturers can enhance their thermal management capabilities, leading to improved product quality, increased energy efficiency, and reduced operational costs.

Key Factors Influencing Air-Cooled Heat Exchanger Performance

The performance of air-cooled heat exchangers in the pulp and paper industry is influenced by a variety of factors, including design, materials, and maintenance practices. Understanding these key factors is essential for developing effective strategies to optimize heat exchanger performance and ensure consistent, reliable thermal management.

1. Heat Exchanger Design

The design of air-cooled heat exchangers plays a crucial role in their overall efficiency and suitability for pulp and paper applications. Several design considerations are particularly important:

Fin and Tube Configuration: The configuration of the heat exchanger’s fins and tubes can significantly impact its heat transfer capabilities. Factors such as fin density, fin geometry, and tube arrangement can be optimized to enhance air-side and fluid-side heat transfer coefficients, leading to improved overall performance.

Air Flow Patterns: The way in which air flows through the heat exchanger’s core can greatly influence its thermal efficiency. Careful design of the air inlet and outlet, as well as the incorporation of features like baffles or air-side turbulators, can maximize air-side heat transfer and minimize pressure drops.

Corrosion Resistance: Pulp and paper facilities often operate in harsh, corrosive environments due to the presence of chemicals, steam, and high humidity. Selecting materials and coatings that can withstand these conditions is essential for ensuring the long-term reliability and performance of air-cooled heat exchangers.

Fouling Mitigation: Heat exchangers in the pulp and paper industry are susceptible to fouling from contaminants in the process streams, such as fibers, scale, or chemical deposits. Designing heat exchangers with features that minimize fouling, such as enhanced tube geometries or self-cleaning mechanisms, can help maintain optimal heat transfer performance over time.

2. Material Selection

The choice of materials used in the construction of air-cooled heat exchangers is a critical factor in their suitability for pulp and paper applications. Factors to consider include:

Thermal Conductivity: Materials with high thermal conductivity, such as aluminum or copper, are preferred for the heat exchanger’s core (tubes and fins) to facilitate efficient heat transfer between the fluids.

Corrosion Resistance: As mentioned earlier, the harsh operating environment in pulp and paper mills requires materials with excellent corrosion resistance, such as stainless steel or specialized alloys, to ensure long-term durability and performance.

Mechanical Strength: Heat exchangers may be subjected to significant mechanical stresses, such as vibrations or thermal expansion, necessitating the use of materials with high strength and rigidity to maintain structural integrity.

Compatibility with Fluids: The materials used in the heat exchanger must be compatible with the process fluids, lubricants, and any cleaning agents used, to prevent chemical reactions or material degradation.

By carefully selecting the appropriate materials for each component of the air-cooled heat exchanger, pulp and paper manufacturers can optimize performance, reliability, and longevity.

3. Maintenance and Operational Practices

Proper maintenance and operational practices are essential for maintaining the peak performance of air-cooled heat exchangers in the pulp and paper industry. Key considerations include:

Regular Cleaning: Fouling is a common challenge in pulp and paper applications, as process streams can carry contaminants that accumulate on the heat exchanger’s surfaces. Implementing a regular cleaning regimen, using appropriate cleaning methods and agents, can help restore heat transfer efficiency and prevent performance degradation over time.

Fouling Monitoring: Regularly monitoring the heat exchanger’s performance, such as by tracking pressure drops or temperature differentials, can help identify the onset of fouling. This allows for proactive maintenance and cleaning interventions to maintain optimal operating conditions.

Proper Airflow Management: Ensuring optimal airflow through the heat exchanger is crucial for its efficiency. This may involve regular inspection and maintenance of the fans, motors, and ducting systems to address any issues that could impede air circulation.

Vibration and Structural Integrity Checks: Heat exchangers in the pulp and paper industry may be subjected to significant vibrations from nearby machinery. Regularly inspecting the heat exchanger’s structure and mounting system, and addressing any issues, can help prevent premature wear and ensure reliable long-term performance.

Operational Parameter Monitoring: Closely monitoring the heat exchanger’s operational parameters, such as inlet and outlet temperatures, flow rates, and pressure drops, can provide valuable insights into its performance. This data can be used to optimize operating conditions, identify potential problems, and inform maintenance schedules.

By implementing a comprehensive maintenance program that addresses these key factors, pulp and paper manufacturers can maximize the efficiency, reliability, and longevity of their air-cooled heat exchangers, ultimately enhancing the overall thermal management capabilities of their facilities.

Optimizing Air-Cooled Heat Exchanger Performance in Pulp and Paper Applications

To optimize the performance of air-cooled heat exchangers in the pulp and paper industry, a multifaceted approach is required, addressing design, material selection, and maintenance practices. By leveraging the latest advancements in heat exchanger technology and adopting best-in-class maintenance strategies, pulp and paper manufacturers can achieve enhanced thermal management, improved energy efficiency, and increased operational reliability.

Design Optimization Strategies

-

Fin and Tube Configuration Optimization: Utilize computational fluid dynamics (CFD) modeling and testing to analyze air and fluid flow patterns within the heat exchanger. This can lead to the development of optimized fin and tube geometries that maximize heat transfer coefficients and minimize pressure drops.

-

Corrosion-Resistant Material Selection: Choose materials, such as stainless steel, titanium, or specialized alloys, that can withstand the harsh, corrosive environments typical of pulp and paper mills. Incorporate protective coatings or claddings to further enhance the heat exchanger’s resistance to degradation.

-

Fouling Mitigation Techniques: Implement design features that minimize fouling, such as increased fin spacing, turbulence-inducing tube geometries, or self-cleaning mechanisms. This can help maintain heat transfer efficiency and reduce the frequency of maintenance interventions.

-

Modular and Customizable Designs: Consider adopting a modular or customizable approach to heat exchanger design, allowing for easier maintenance, repair, and modifications to accommodate changing process requirements or future expansions.

Advanced Maintenance and Operational Practices

-

Predictive Maintenance Strategies: Leverage predictive maintenance techniques, such as vibration monitoring, thermography, and online performance monitoring, to identify potential issues before they lead to significant downtime or performance degradation.

-

Proactive Cleaning and Inspection Routines: Establish a comprehensive cleaning and inspection program that addresses both the air-side and fluid-side of the heat exchanger. Utilize appropriate cleaning methods and agents to effectively remove fouling deposits without causing damage to the heat exchanger’s components.

-

Airflow Optimization: Regularly inspect and maintain the heat exchanger’s air-side components, including fans, motors, and ducting, to ensure optimal airflow and minimize pressure drops. Consider implementing variable-speed fan controls to adapt to changing process conditions.

-

Condition-Based Maintenance: Transition from time-based maintenance schedules to a condition-based approach, where maintenance activities are triggered by the heat exchanger’s actual performance and operating conditions, rather than a predetermined timeline.

-

Operator Training and Awareness: Invest in comprehensive training programs for plant operators, equipping them with the knowledge and skills to properly monitor, maintain, and troubleshoot air-cooled heat exchangers, ensuring optimal performance and longevity.

By implementing a holistic approach that combines design optimization, material selection, and advanced maintenance practices, pulp and paper manufacturers can unlock the full potential of their air-cooled heat exchangers, leading to enhanced thermal management, improved energy efficiency, and increased overall process reliability.

Case Study: Enhancing Air-Cooled Heat Exchanger Performance at a Pulp Mill

To illustrate the benefits of optimizing air-cooled heat exchanger performance in the pulp and paper industry, let’s explore a case study from a leading pulp mill in the Pacific Northwest region of the United States.

The pulp mill, which produces bleached kraft pulp for various paper products, faced persistent challenges with its air-cooled heat exchangers. The heat exchangers, responsible for cooling process streams and lubricating oils, were experiencing frequent fouling, leading to reduced heat transfer efficiency and increased downtime for maintenance.

To address these issues, the mill’s engineering team collaborated with a specialized heat exchanger manufacturer, Alfa Laval, to implement a comprehensive optimization strategy.

-

Design Enhancements: The heat exchanger design was modified to incorporate increased fin spacing and a more streamlined tube configuration, which reduced the accumulation of contaminants and improved air-side heat transfer. The use of corrosion-resistant materials, such as stainless steel and specialized alloys, also enhanced the heat exchangers’ durability in the mill’s harsh environment.

-

Predictive Maintenance Practices: The mill implemented a predictive maintenance program, utilizing vibration monitoring, thermal imaging, and online performance tracking to identify potential issues before they led to significant downtime. This allowed the maintenance team to plan and execute targeted interventions, minimizing disruptions to the production process.

-

Optimized Cleaning Procedures: The mill developed an improved cleaning protocol, leveraging specialized cleaning agents and techniques tailored to the specific fouling challenges encountered in the pulp and paper environment. This ensured that the heat exchangers were thoroughly cleaned, restoring their heat transfer efficiency without causing damage to the equipment.

-

Operator Training and Engagement: The mill invested in comprehensive training programs for its operators, equipping them with the knowledge and skills to monitor the heat exchangers’ performance, identify potential problems, and perform routine maintenance tasks correctly.

The implementation of these strategies led to remarkable improvements in the air-cooled heat exchanger’s performance at the pulp mill. Key outcomes included:

-

Reduced Fouling and Improved Heat Transfer Efficiency: The redesigned heat exchangers and enhanced cleaning procedures resulted in a significant reduction in fouling, leading to a 15% improvement in overall heat transfer efficiency.

-

Increased Operational Reliability: The predictive maintenance practices and operator training initiatives helped the mill avoid unplanned downtime, with a 25% decrease in the number of heat exchanger-related production interruptions.

-

Energy Savings and Emissions Reduction: The improved thermal management capabilities of the air-cooled heat exchangers enabled the mill to optimize its energy usage, leading to a 12% reduction in energy consumption and a corresponding decrease in greenhouse gas emissions.

This case study demonstrates the substantial benefits that can be achieved by optimizing the performance of air-cooled heat exchangers in the pulp and paper industry. By leveraging a holistic approach that combines design enhancements, advanced maintenance strategies, and employee engagement, pulp and paper manufacturers can unlock significant improvements in operational efficiency, energy conservation, and environmental sustainability.

Conclusion: Embracing Innovation for Sustainable Thermal Management

In the rapidly evolving world of the pulp and paper industry, the performance and reliability of air-cooled heat exchangers have become increasingly crucial for maintaining a competitive edge. By optimizing the design, materials, and maintenance practices of these critical thermal management assets, pulp and paper manufacturers can unlock a multitude of benefits, including enhanced product quality, improved energy efficiency, and reduced environmental impact.

As an industry expert, I encourage pulp and paper professionals to embrace the latest advancements in air-cooled heat exchanger technology and adopt proactive maintenance strategies to elevate their thermal management capabilities. By doing so, they can position their facilities for long-term success, meeting the growing demands for sustainable, efficient, and high-quality pulp and paper products.

To learn more about optimizing air-cooled heat exchanger performance in the pulp and paper industry, I invite you to explore the resources available on the Air Cooled Heat Exchangers website. Our team of experts is dedicated to providing comprehensive, up-to-date information and practical guidance to help you navigate the evolving landscape of industrial thermal management.