Unlocking the Power of Air-Cooled Heat Exchangers in Aerospace

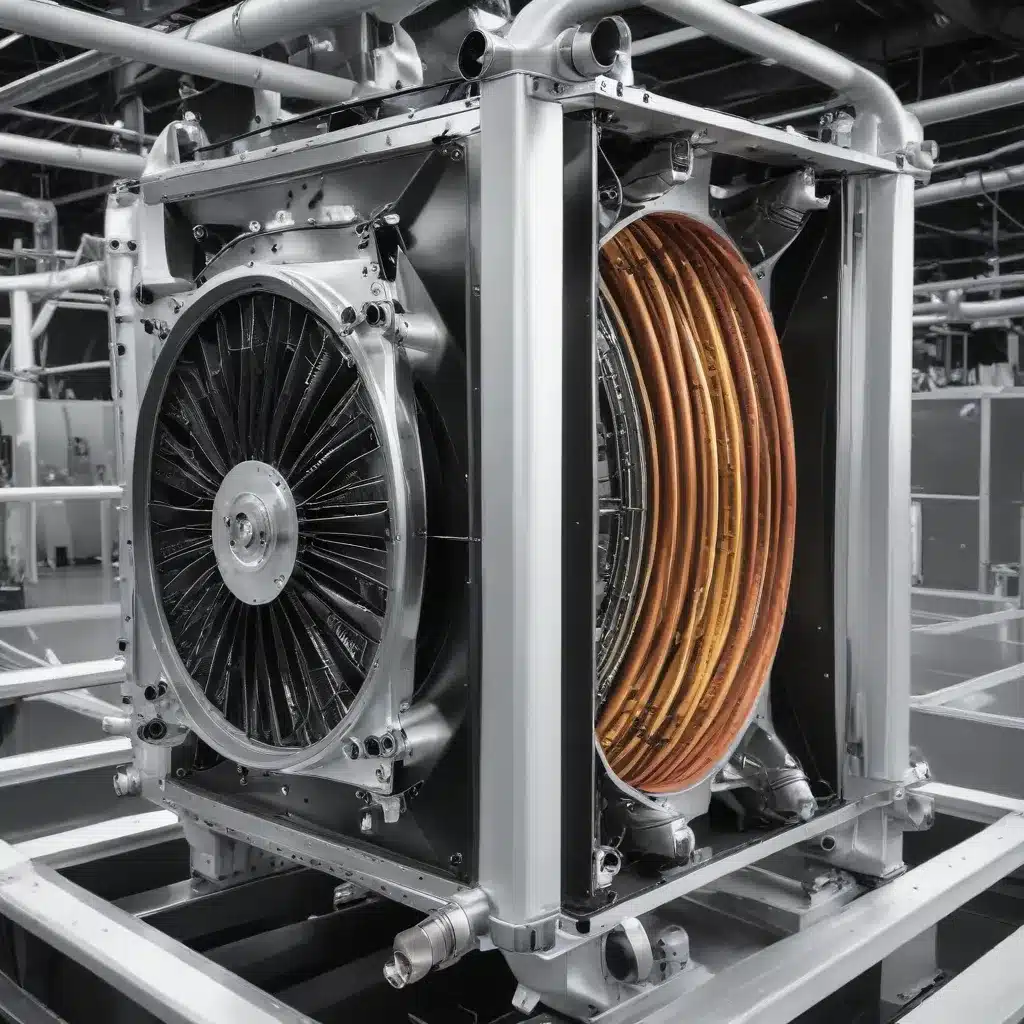

As the aerospace industry continues to push the boundaries of innovation, the role of air-cooled heat exchangers has become increasingly vital in ensuring the reliable and efficient thermal management of critical aircraft systems. Whether it’s the hydraulics, avionics, environmental control systems (ECS), or engine components, these unsung heroes of thermal engineering play a pivotal part in maintaining the safety and performance of modern commercial and military aircraft.

At https://www.aircooledheatexchangers.net/, we’ve dedicated ourselves to exploring the nuances of air-cooled heat exchanger design, engineering, and optimization, with a particular focus on their applications in the aerospace sector. In this comprehensive article, we’ll dive deep into the world of air-cooled heat exchangers, uncovering practical tips, in-depth insights, and industry-leading techniques to help aerospace engineers and professionals enhance the thermal management capabilities of their aircraft.

Understanding the Unique Challenges of Aerospace Thermal Management

The aerospace industry presents a unique set of challenges when it comes to thermal management. Aircraft operate in demanding environments, with fluctuating ambient temperatures, high-altitude conditions, and the need for robust, lightweight, and compact cooling solutions. Traditional liquid-cooled heat exchangers can often be too bulky and heavy for aircraft applications, making air-cooled heat exchangers the preferred choice for many aerospace engineers.

However, optimizing the performance of air-cooled heat exchangers in the aerospace context requires a deep understanding of the intricate interplay between aerodynamics, thermal dynamics, and material science. Factors such as airflow patterns, heat transfer coefficients, and the selection of durable, high-performance materials all play a crucial role in ensuring the reliable and efficient operation of these critical components.

Advancing Air-Cooled Heat Exchanger Design for Aerospace Applications

At https://www.aircooledheatexchangers.net/, we’ve partnered with leading aerospace manufacturers like AMETEK Hughes-Treitler to develop state-of-the-art air-cooled heat exchanger solutions that meet the stringent requirements of the aviation industry. These advanced heat exchangers are engineered to deliver superior thermal management capabilities, ensuring the optimal performance and reliability of various aircraft systems.

Aerodynamic Optimization for Improved Airflow

One of the key focus areas in air-cooled heat exchanger design for aerospace is the optimization of airflow patterns. By carefully modeling and simulating the fluid dynamics within the heat exchanger, our engineers can optimize the fin geometry, tube arrangements, and overall casing design to maximize the heat transfer while minimizing pressure drop and drag. This aerodynamic optimization ensures that the air-cooled heat exchanger can effectively dissipate heat without compromising the aircraft’s overall aerodynamic performance.

Advanced Materials and Manufacturing Techniques

The harsh operating environments of aircraft, from extreme temperatures to vibrations and mechanical stresses, require the use of durable, high-performance materials in air-cooled heat exchanger construction. Our team of material scientists and engineers works closely with aerospace manufacturers to identify the optimal materials, such as high-strength aluminum alloys or corrosion-resistant stainless steels, and implement advanced manufacturing techniques like precision casting, laser welding, and additive manufacturing to create heat exchangers that can withstand the rigors of aerospace applications.

Customized Thermal Management Solutions

Every aircraft and its associated systems have unique cooling requirements, necessitating a tailored approach to air-cooled heat exchanger design. At https://www.aircooledheatexchangers.net/, we collaborate closely with our aerospace partners to develop customized thermal management solutions that address their specific challenges. This includes the integration of advanced features like modular designs, variable-speed fans, and intelligent control systems to optimize heat exchanger performance and adaptability to changing operational conditions.

Maintaining Peak Air-Cooled Heat Exchanger Performance

Ensuring the long-term reliability and efficiency of air-cooled heat exchangers in aerospace applications is crucial, as these critical components play a pivotal role in the safety and performance of aircraft. Our team of experts at https://www.aircooledheatexchangers.net/ have developed a comprehensive set of maintenance and optimization strategies to help aerospace professionals keep their air-cooled heat exchangers operating at peak performance.

Proactive Maintenance and Cleaning Protocols

Regular inspection and maintenance of air-cooled heat exchangers are essential to prevent performance degradation and ensure their long-term reliability. This includes implementing thorough cleaning protocols to remove accumulated dirt, debris, and contaminants from the heat exchanger surfaces, as well as monitoring for signs of corrosion, fouling, or mechanical damage. By adopting a proactive maintenance approach, aerospace professionals can extend the service life of their air-cooled heat exchangers and maintain optimal thermal management capabilities.

Periodic Performance Assessments

Regularly evaluating the thermal and aerodynamic performance of air-cooled heat exchangers is crucial for identifying any potential issues or opportunities for optimization. This can involve conducting detailed heat transfer and fluid dynamics analyses, as well as measuring key performance metrics such as heat transfer rates, pressure drops, and airflow characteristics. By leveraging advanced diagnostic tools and data-driven insights, aerospace professionals can gain valuable insights into the health and efficiency of their air-cooled heat exchangers, enabling them to make informed decisions about maintenance, repairs, or upgrades.

Innovative Monitoring and Control Systems

Emerging technologies in the realm of sensor integration, data analytics, and intelligent control systems are transforming the way air-cooled heat exchangers are managed in aerospace applications. By implementing advanced monitoring systems that track real-time operational parameters, such as temperatures, airflow, and vibration levels, aerospace professionals can proactively detect and address any performance deviations or potential failures. Furthermore, the integration of smart control algorithms can enable the dynamic optimization of air-cooled heat exchanger operation, adjusting fan speeds, airflow patterns, and other parameters to ensure the most efficient and reliable thermal management.

Embracing the Future of Air-Cooled Heat Exchangers in Aerospace

As the aerospace industry continues to push the boundaries of innovation, the role of air-cooled heat exchangers will only become more critical in maintaining the safety, performance, and efficiency of aircraft. At https://www.aircooledheatexchangers.net/, we are committed to staying at the forefront of air-cooled heat exchanger technology, collaborating with leading aerospace manufacturers to develop cutting-edge solutions that address the evolving thermal management challenges faced by the industry.

By leveraging advanced design techniques, innovative materials, and smart monitoring and control systems, we are redefining the capabilities of air-cooled heat exchangers in aerospace applications. From optimizing airflow patterns to enhancing durability and reliability, our team of experts is dedicated to empowering aerospace professionals with the tools and insights they need to achieve the highest levels of thermal management performance.

As you navigate the complexities of air-cooled heat exchanger selection, design, and maintenance for your aerospace applications, we invite you to explore the wealth of resources and support available at https://www.aircooledheatexchangers.net/. Together, let’s unlock the full potential of air-cooled heat exchangers and elevate the thermal management capabilities of the aerospace industry to new heights.