Unlocking the Power of Air-Cooled Heat Exchangers: A Comprehensive Guide

In the ever-evolving world of industrial processes, effective thermal management is the cornerstone of efficiency and sustainability. At the heart of this challenge lies the air-cooled heat exchanger, a versatile and ubiquitous technology that enables countless industries to maintain optimal operating conditions. As a seasoned expert in this domain, I’m excited to share cutting-edge strategies and practical insights to help you unlock the full potential of your air-cooled heat exchangers.

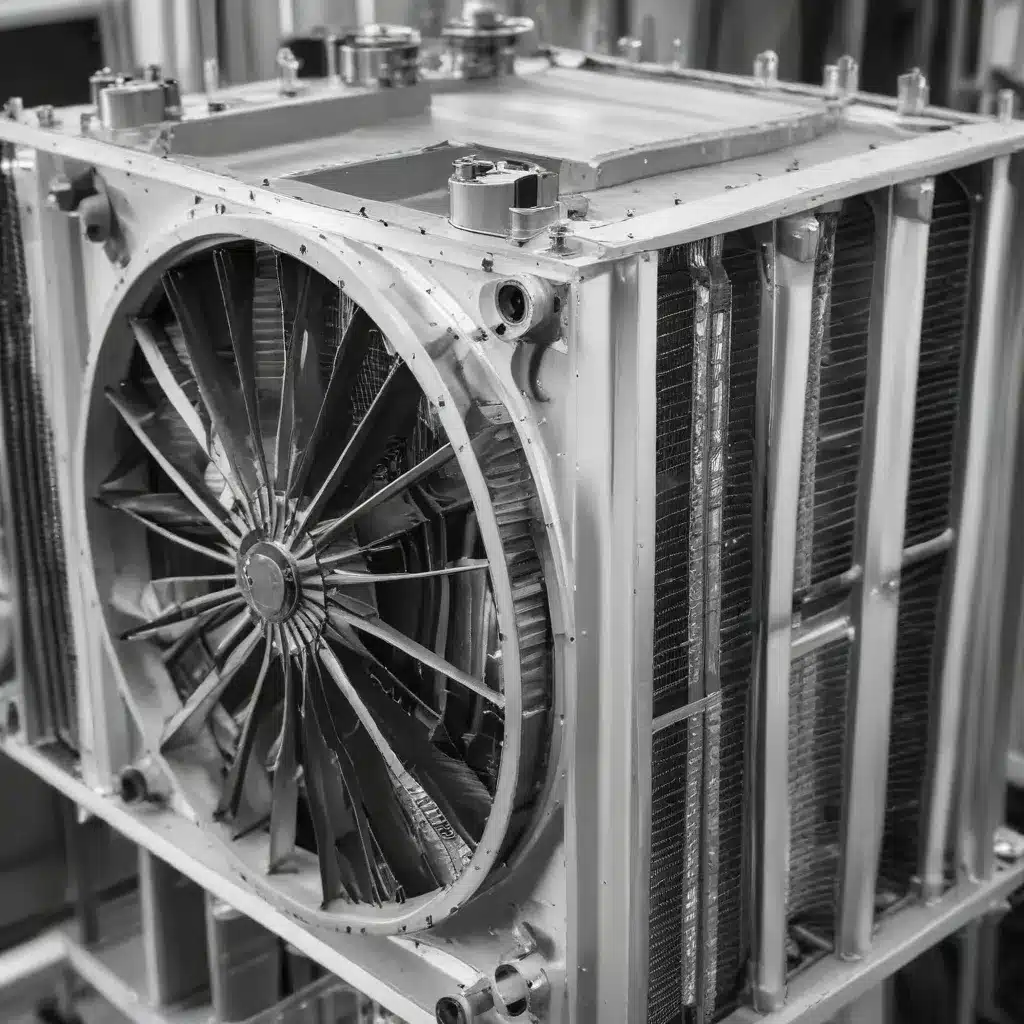

Understanding the Fundamentals of Air-Cooled Heat Exchangers

Air-cooled heat exchangers are a crucial component in a wide range of applications, from manufacturing and energy production to data centers and HVAC systems. These robust, reliable, and energy-efficient devices leverage the inherent properties of air to facilitate the transfer of thermal energy, making them an indispensable tool in the quest for sustainable and efficient operations.

At their core, air-cooled heat exchangers utilize finned tubes or plates to maximize the surface area exposed to the surrounding air, allowing for efficient heat dissipation. By strategically designing the tube or plate geometry, material selection, and airflow patterns, engineers can optimize the heat transfer capabilities of these systems, ensuring that critical equipment and processes remain within their optimal temperature ranges.

Leveraging Cutting-Edge Cooling Strategies

In the ever-evolving landscape of industrial thermal management, air-cooled heat exchangers have continued to evolve, with a range of cutting-edge cooling strategies emerging to enhance their performance and efficiency. Let’s explore some of these transformative approaches:

Liquid Cooling: Maximizing Heat Dissipation

Liquid cooling is an advanced and highly effective method for managing heat in industrial operations. This approach involves the use of a liquid coolant that circulates through a closed-loop system, absorbing heat from the equipment and dissipating it through a heat exchanger or radiator. Commonly used liquid coolants include water, propylene glycol, and ethylene glycol, each with its own unique thermal properties and compatibility considerations.

By leveraging the superior heat transfer capabilities of liquids, liquid cooling solutions can outperform traditional air-cooled systems, enabling industries to maintain peak performance even during the most intensive operations. This approach is particularly useful in high-heat environments, where air-cooled systems may struggle to keep up with the thermal demands.

Immersion Cooling: Submerging for Superior Efficiency

Immersion cooling is an innovative and highly effective method of cooling industrial equipment by submerging it directly into a non-conductive liquid coolant. This technique allows the generated heat to be rapidly and evenly absorbed by the coolant, resulting in exceptional heat dissipation without the need for complex pumps, hoses, or radiators.

Immersion cooling systems offer several advantages over traditional air-cooled or liquid-cooled solutions, including:

- Enhanced cooling efficiency: The direct contact between the equipment and the coolant allows for rapid and uniform heat transfer, ensuring optimal temperature control.

- Reduced energy consumption: The simplified design and the inherent efficiency of immersion cooling can lead to significant energy savings compared to other cooling methods.

- Noise reduction: The absence of fans or pumps in immersion cooling systems results in a quieter operating environment.

- Simplified maintenance: Immersion cooling systems typically require less maintenance, as they have fewer moving parts and are less susceptible to dust and debris buildup.

When implementing immersion cooling, it’s essential to carefully select the appropriate non-conductive liquid coolant and ensure that the equipment is properly sealed and submerged to maximize the benefits of this innovative approach.

Direct-to-Chip Cooling: Targeted Thermal Management

Direct-to-chip cooling is a highly targeted method of managing heat in industrial equipment, focusing on dissipating heat directly from the primary heat-generating components, such as processors or GPU chips. This approach involves attaching specialized heat sinks or cooling blocks directly to the surface of the critical components, facilitating efficient heat transfer through thermally conductive materials.

By addressing the heat source directly, direct-to-chip cooling can provide several advantages, including:

- Improved thermal efficiency: The targeted cooling approach ensures that the hottest components receive the most effective cooling, optimizing overall thermal management.

- Increased component lifespan: Reducing the operating temperatures of critical components can significantly extend their lifespan and reliability.

- Enhanced system stability: Maintaining optimal temperatures helps prevent thermal-related performance issues or system failures.

When implementing direct-to-chip cooling, the selection of the right heat sink or cooling block material is crucial, as thermal conductivity plays a vital role in the efficiency of the heat transfer process. Materials such as copper, aluminum, and specialized thermal interface compounds can be employed to maximize the effectiveness of this cooling strategy.

Optimizing Air Circulation and Environmental Factors

In addition to advanced cooling techniques, strategic air circulation and environmental considerations can greatly enhance the performance of air-cooled heat exchangers. Let’s explore some of these key strategies:

Harnessing the Power of Ambient Temperatures

Choosing a geographically cooler region for your industrial operations can play a significant role in temperature management. Cooler climates provide natural environmental benefits, reducing the need for extensive cooling systems and lowering overall operational costs. By setting up your operations in a location with lower average temperatures, you can take advantage of the ambient surroundings and make it easier to maintain optimal equipment performance.

Furthermore, leveraging underground facilities can offer additional thermal management advantages. Underground environments typically provide more stable temperatures, as they are less affected by external weather conditions. This can lead to reduced energy consumption, enhanced security, and improved noise reduction, all of which contribute to the overall efficiency and sustainability of your operations.

Enhancing Air Circulation with Rack-Mount Cooling Fans and Ducted Systems

Effective air circulation is crucial for maintaining optimal temperatures within an air-cooled heat exchanger system. Rack-mount cooling fans, designed to attach directly to the equipment racks, can play a vital role in drawing hot air away from the hardware and exhausting it outside the operating environment.

Complementing rack-mount fans, ducted airflow systems offer a powerful solution for distributing conditioned air throughout the industrial space. These systems use a network of ducts to ensure even and unrestricted airflow, promoting better heat dissipation and more uniform temperature distribution.

By implementing a combination of rack-mount cooling fans and ducted airflow systems, you can significantly improve the air circulation within your air-cooled heat exchanger setup, leading to enhanced cooling efficiency and overall equipment performance.

Maintaining Peak Performance through Proactive Maintenance

Ensuring the long-term efficiency and reliability of air-cooled heat exchangers requires a proactive approach to maintenance. Regular inspections, cleaning, and component replacements are crucial steps in preserving the optimal performance of these critical systems.

Dust Removal and Cleaning Protocols

Dust and debris accumulation can have a detrimental impact on the performance of air-cooled heat exchangers, obstructing airflow and hindering heat dissipation. To maintain optimal efficiency, adhere to a regular cleaning schedule, which may involve the following steps:

- Regularly inspect the heat exchanger for dust and debris buildup, paying close attention to the finned tubes or plates.

- Use compressed air, soft-bristle brushes, or specialized cleaning tools to gently remove any accumulated dust and debris.

- Ensure that all surfaces are thoroughly cleaned, including the heat exchanger core, fans, and any accessible components.

- Adjust the cleaning frequency based on the operating environment and the intensity of use, as equipment in dusty or heavily utilized settings may require more frequent attention.

Consistent and thorough cleaning helps to maintain unobstructed airflow, ensuring that the heat exchanger can operate at its optimal efficiency and maximize the cooling performance of your industrial systems.

Fault Detection and Component Replacement

Detecting and addressing faulty components is essential for maintaining the long-term reliability and performance of air-cooled heat exchangers. Regular inspections and monitoring can help identify any potential issues, allowing you to proactively address them before they lead to more significant problems.

Some key steps in this process include:

- Regularly monitor the performance indicators of your air-cooled heat exchanger, such as temperatures, pressure drops, and energy consumption.

- Visually inspect the system for any signs of wear, corrosion, or damage to critical components, such as the fan motors, bearings, or tubes.

- Perform routine maintenance checks, following the manufacturer’s recommendations, to identify and address any emerging faults or malfunctions.

- Promptly replace any faulty or underperforming components to ensure the continued reliability and efficiency of your air-cooled heat exchanger.

By staying vigilant and proactively addressing any issues, you can extend the lifespan of your air-cooled heat exchanger and maintain its optimal performance, minimizing the risk of unexpected downtime or costly repairs.

Integrating Advanced Monitoring and Control Technologies

In the era of Industry 4.0, the integration of advanced monitoring and control technologies can significantly enhance the performance and efficiency of air-cooled heat exchangers. These innovative solutions provide real-time insights and enable remote management, empowering operators to make informed decisions and optimize their thermal management strategies.

Temperature Sensors and Remote Monitoring

Temperature sensors play a crucial role in maintaining optimal performance and preventing potential hardware damage due to overheating. By strategically placing these sensors throughout your air-cooled heat exchanger system, you can continuously monitor the temperatures of critical components and the surrounding environment.

To further enhance temperature monitoring capabilities, consider implementing remote monitoring solutions that leverage internet connectivity to provide real-time visibility of your system’s thermal conditions from a distance. These solutions often include intuitive dashboards or mobile applications, allowing you to monitor and respond to any temperature fluctuations or emerging issues, even from a remote location.

The benefits of integrating temperature sensors and remote monitoring into your air-cooled heat exchanger setup include:

- Early detection of potential issues: Continuous temperature monitoring enables you to identify and address problems before they escalate.

- Optimized performance: Real-time data allows you to make informed decisions to maintain peak efficiency and prevent equipment damage.

- Improved maintenance scheduling: Monitoring trends and patterns can help you optimize your maintenance routines, reducing downtime and extending the lifespan of your systems.

- Enhanced remote management capabilities: The ability to monitor and control your air-cooled heat exchanger from anywhere empowers you to respond quickly to any changes or emergencies.

By embracing these advanced monitoring and control technologies, you can elevate the performance and reliability of your air-cooled heat exchanger systems, driving greater efficiency and profitability in your industrial operations.

Customizing Cooling Solutions for Optimal Results

Every industrial application and environment is unique, requiring a tailored approach to effectively manage thermal challenges. By customizing the cooling solutions for your air-cooled heat exchanger systems, you can achieve optimal performance and unlock the full potential of your thermal management strategies.

When customizing your cooling solutions, consider the following key factors:

-

Application-Specific Needs: Assess the unique requirements of your industry, process, or equipment to determine the most suitable cooling approach. For example, a data center may have different cooling needs compared to a manufacturing facility.

-

Environmental Conditions: Evaluate the ambient temperature, humidity, and airflow patterns in your operating environment, as these factors can significantly impact the effectiveness of your air-cooled heat exchanger.

-

Heat Load and Dissipation Requirements: Accurately determine the heat load generated by your equipment or processes, and ensure that your cooling solution can effectively dissipate the required thermal energy.

-

Integration with Existing Infrastructure: Consider how the air-cooled heat exchanger will integrate with your current systems, such as power supply, control systems, and existing cooling infrastructure.

-

Energy Efficiency and Sustainability: Prioritize solutions that not only meet your cooling needs but also optimize energy consumption and align with your sustainability goals.

By taking these factors into account and collaborating with experienced thermal management experts, you can develop a customized cooling solution that seamlessly integrates with your air-cooled heat exchanger, ensuring optimal performance, energy efficiency, and long-term reliability.

Conclusion: Elevating Air-Cooled Heat Exchanger Performance

Air-cooled heat exchangers are the unsung heroes of industrial thermal management, quietly maintaining optimal operating conditions across a wide range of industries. By embracing cutting-edge cooling strategies, enhancing air circulation, implementing proactive maintenance practices, and leveraging advanced monitoring and control technologies, you can unlock the full potential of your air-cooled heat exchanger systems.

Whether you’re tackling the challenges of high-heat environments, seeking to improve energy efficiency, or striving for long-term reliability, the strategies outlined in this comprehensive guide can help you achieve your thermal management goals. By customizing your cooling solutions and staying at the forefront of industry innovations, you can elevate the performance of your air-cooled heat exchangers, drive sustainable operations, and maximize the profitability of your industrial endeavors.

For more information and personalized support in optimizing your air-cooled heat exchanger systems, visit https://www.aircooledheatexchangers.net/. Our team of experts is dedicated to providing tailored solutions and round-the-clock assistance to help you master the art of thermal management.