Understanding the Fundamentals of Heat Exchange

Heat exchange is a fundamental concept in thermodynamics that involves the transfer of thermal energy from one object or substance to another. There are three primary mechanisms through which heat can be transferred: conduction, convection, and radiation.

Conduction occurs when heat is transferred through direct contact between two objects or substances. It relies on the principle that heat flows from regions of higher temperature to regions of lower temperature. For example, when you touch a hot stove, heat is conducted from the stove to your hand, resulting in a sensation of burning.

Convection involves the transfer of heat through the movement of fluids (liquids or gases). This mechanism relies on the circulation and mixing of fluid particles due to temperature differences. An everyday example of convection is boiling water in a pot, where the heated water rises to the surface while cooler water sinks, creating a continuous cycle that transfers heat throughout the liquid.

Radiation is the transfer of thermal energy through electromagnetic waves. Unlike conduction and convection, radiation does not require physical contact or a medium for heat transfer. The sun’s rays reaching the Earth are an example of radiation-based heat exchange.

Understanding temperature gradients is crucial for comprehending how heat moves between objects or substances during an exchange process. A temperature gradient refers to the change in temperature per unit length or distance. When there is a significant difference in temperatures between two objects or substances, it creates a steeper temperature gradient and facilitates faster heat transfer.

Thermal conductivity plays a vital role in determining how efficiently materials conduct heat. It measures how easily thermal energy can pass through a material via conduction. Materials with high thermal conductivity allow for efficient heat transfer because they facilitate rapid movement of thermal energy across their structure.

Heat transfer coefficients are essential parameters used to quantify the efficiency of heat transfer between two mediums. They represent the rate at which heat is transferred per unit area and per unit temperature difference between the mediums involved. By understanding these coefficients, engineers and designers can optimize the design to ensure efficient heat exchange while considering factors such as fluid flow rates, temperature differences, and surface area.

These fundamental principles of conduction, convection, radiation, temperature gradients, thermal conductivity, and heat transfer coefficients form the basis for understanding different types of heat exchangers and their applications.

Exploring the Key Types of Heat Exchangers

When it comes to heat exchangers, it’s important to differentiate between direct and indirect heat exchangers. Direct heat exchangers involve the transfer of heat between two fluids that come into direct contact with each other. On the other hand, indirect heat exchangers use a barrier or a partition to separate the two fluids, preventing them from mixing.

Let’s delve into an overview of the main categories of heat exchangers:

Shell and Tube Heat Exchangers

Shell and tube heat exchangers are one of the most common types used in various industries. They consist of a cylindrical shell with multiple tubes running through it. One fluid flows through the tubes while the other flows around them in the shell. This design allows for efficient transfer of heat due to a large surface area available for exchange.

Plate Heat Exchangers

Plate heat exchangers are compact and highly efficient devices that utilize stacked plates to facilitate heat transfer. These plates create alternating channels for both fluids, maximizing contact surface area and promoting effective thermal exchange. Plate heat exchangers are commonly used in applications where space is limited or when there is a need for high rates of heat transfer.

Specialized Heat Exchangers

Apart from shell and tube and plate heat exchangers, there are also specialized types designed for specific purposes. Examples include air-cooled condensers, which use ambient air as the cooling medium instead of water; double-pipe heat exchangers, which consist of two concentric pipes for improved efficiency; and spiral or helical coil heat exchangers that provide enhanced turbulence to enhance thermal performance.

When selecting a suitable type of heat exchanger for an application, it is crucial to consider its specific requirements. Factors such as operating conditions (temperature, pressure), fluid properties (viscosity, corrosiveness), space limitations, and desired heat transfer efficiency should all be taken into account. By understanding the different types of heat exchangers, engineers and designers can make informed decisions to ensure optimal performance and cost-effectiveness.

Delving Deeper into Shell and Tube Heat Exchangers

Shell and tube heat exchangers are a common type of heat exchanger used in various industries such as oil refining, chemical processing, and power generation. These heat exchangers consist of a cylindrical shell with multiple tubes running through it.

In a shell and tube heat exchanger, the cylindrical shell serves as the outer vessel, while the tubes act as the inner channels for fluid flow. The tubes are arranged in a parallel or U-shaped pattern within the shell. One fluid flows inside the tubes (known as the tube side), while the other fluid flows outside the tubes but inside the shell (known as the shell side). The fluids can be gases, liquids, or a combination of both.

Heat transfer occurs through conduction between the fluids across the tube walls. As hot fluid flows through one set of tubes, it transfers its thermal energy to cooler fluid flowing on the other side.

Shell and tube heat exchangers offer several advantages compared to other types:

- High Efficiency: The large surface area provided by the numerous tubes allows for effective cooling or heating of fluids, even with significant temperature differences.

- High-Pressure Capability: These heat exchangers are well-suited for containing high-pressure fluids within their sturdy shells.

- Flexibility in Maintenance: Individual tubes can be easily replaced if damaged or clogged, making maintenance more straightforward.

However, there are some disadvantages to consider as well:

- Larger Size: Shell and tube heat exchangers tend to be larger in size compared to other types, resulting in higher installation costs and increased space requirements.

- Potential for Fouling: The presence of tube-side fouling or scaling can reduce the heat exchanger’s performance over time, requiring regular cleaning and maintenance.

Shell and tube heat exchangers find widespread use in various industries, including:

- Oil Refining: For processes such as crude oil distillation, product cooling, and condensing vapors.

- Chemical Processing: For reactions involving heating or cooling of chemicals.

- Power Generation: In steam condensation and cooling systems.

- HVAC Systems: For heat transfer between air streams.

By understanding the design and characteristics of shell and tube heat exchangers, engineers and designers can select the most appropriate option for their specific application requirements.

Exploring the Advantages of Plate Heat Exchangers

Plate heat exchangers are a popular type of heat exchanger that use multiple thin plates to transfer heat between two fluids. These heat exchangers consist of alternating layers of plates, which create channels for the fluids to flow through.

One of the main benefits of plate heat exchangers is their compact size. The compact design makes them ideal for applications where space is limited, such as in HVAC systems or small processing plants. Despite their small size, plate heat exchangers offer high efficiency in transferring heat between fluids due to the large surface area provided by the numerous plates.

Maintenance of plate heat exchangers is relatively easy compared to other types of heat exchangers. The individual plates can be easily removed and cleaned, making it simple to maintain optimal performance and prevent fouling or scaling issues. This ease of maintenance contributes to the longevity and reliability of these heat exchangers.

Plate heat exchangers find applications in various industries due to their versatility and efficiency. In HVAC systems, they are commonly used for heating or cooling purposes, efficiently transferring thermal energy between air and water streams. In food processing plants, plate heat exchangers play a crucial role in pasteurization and sterilization processes, ensuring safe food production. They are also utilized in refrigeration systems for condensing or evaporating refrigerant gases.

Another industrial application where plate heat exchangers excel is in industrial processes involving phase change operations. These operations include condensation or evaporation processes where there is a significant temperature difference between the two fluids involved. With their efficient design, plate heat exchangers facilitate rapid phase change while maintaining high thermal efficiency.

Pillow plate heat exchangers represent a specialized type within the category of plate heat exchangers. These heat exchangers consist of plates with laser-welded channels, creating a pillow-like structure. Pillow plate heat exchangers are commonly used in industries such as dairy, pharmaceuticals, and chemical processing, where precise temperature control is essential.

By understanding the advantages of plate heat exchangers, including their compact size, high efficiency, and ease of maintenance, engineers and designers can select the most appropriate option for their specific application requirements.

Specialized Heat Exchangers: Tailored Solutions for Unique Needs

Specialized heat exchangers are designed for specific applications and offer unique features to meet the requirements of various industries. Let’s take a closer look at some of these specialized types:

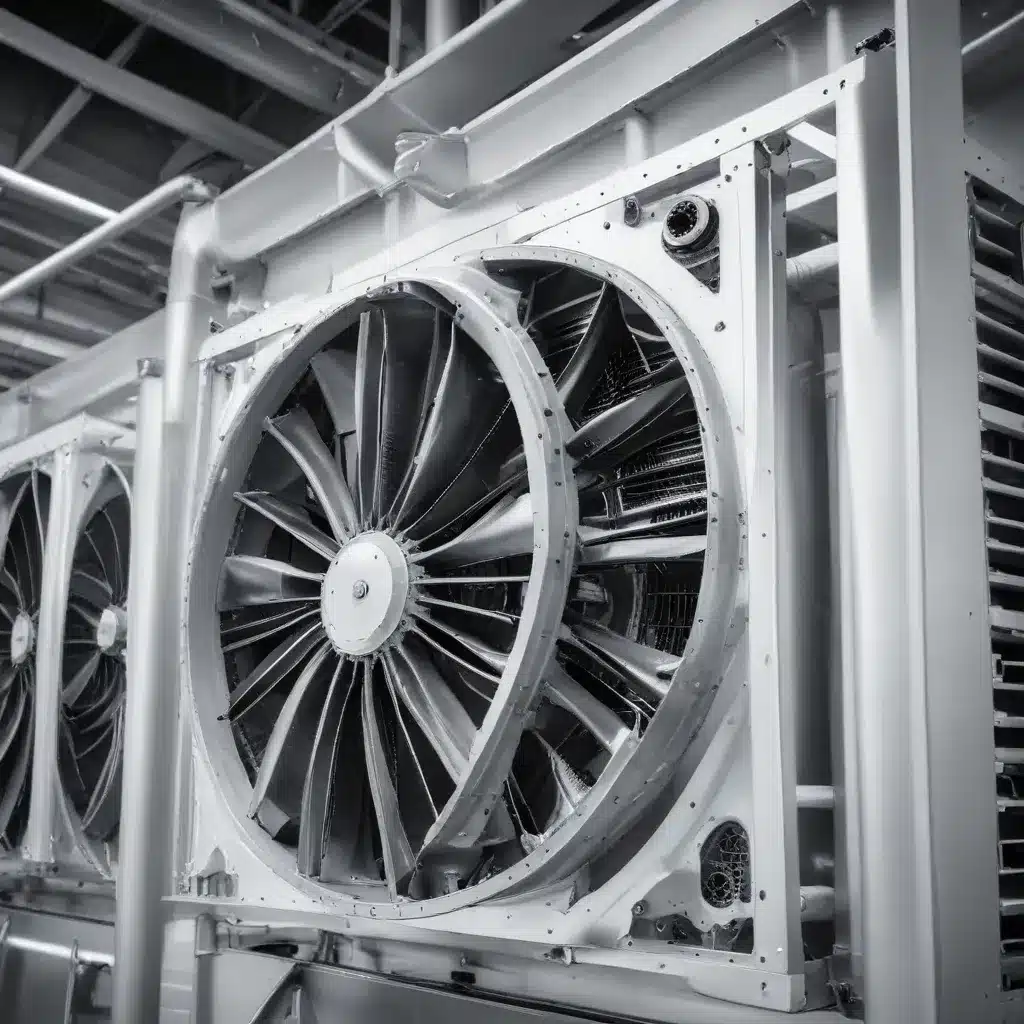

Air-Cooled Heat Exchangers

Air-cooled heat exchangers, as the name suggests, use ambient air to cool down the process fluid. They are commonly used in industries where water is scarce or expensive. These exchangers have finned tubes that increase the surface area for better heat transfer. The hot fluid flows through the tubes while fans blow air over them, dissipating the heat into the surrounding atmosphere.

Double-Pipe Heat Exchangers

Double-pipe heat exchangers consist of two concentric pipes with one fluid flowing inside the inner pipe and another fluid flowing through the outer annular space. This design allows for efficient heat transfer between two fluids without mixing them. Double-pipe exchangers are often used in applications where there is a significant temperature difference between the two fluids or when handling corrosive materials.

Regenerative Heat Exchangers

Regenerative heat exchangers are employed in systems where waste heat can be recovered and reused. These exchangers utilize a matrix of solid material, such as ceramic or metal, which absorbs and releases heat during cyclic operations. The hot fluid transfers its thermal energy to the matrix while flowing through it. Later, during a different phase of operation, cold fluid passes through the same matrix and extracts the stored thermal energy.

Spiral Heat Exchangers

Spiral heat exchangers feature a unique design with two parallel flow channels that coil around each other like a spiral staircase. This configuration allows for high turbulence and maximizes the contact surface area between fluids for efficient heat transfer. Spiral exchangers are commonly used in applications where fouling is a concern, such as in the food processing industry.

Each of these specialized heat exchangers offers distinct advantages for specific applications. For example, air-cooled exchangers are suitable for industries located in arid regions or where water conservation is crucial. Double-pipe exchangers excel when handling fluids with extreme temperature differences or corrosive properties. Regenerative exchangers are ideal for waste heat recovery systems, while spiral exchangers are effective in preventing fouling.

By understanding the different types of specialized heat exchangers and their unique features, engineers and designers can select the right heat exchanger for their specific needs, optimizing energy efficiency, reducing costs, and enhancing overall performance.

Key Considerations in Heat Exchanger Design

There are several key considerations that engineers take into account when designing heat exchangers. These design features play a crucial role in determining the efficiency and effectiveness of the heat exchanger.

Surface Area: The selection of an appropriate surface area is a primary design characteristic. A larger surface area allows for more efficient heat transfer, as it provides a greater contact area for the exchange to occur. Designers often aim to maximize surface area while considering practical constraints such as cost and space limitations.

Flow Arrangement: Another crucial aspect is the decision on the flow arrangement within the exchanger. There are two main options: parallel flow and counterflow configurations. In a parallel flow heat exchanger, both fluids enter at one end and travel in the same direction before exiting at the other end. In a counterflow configuration, the fluids enter at opposite ends and flow in opposite directions before exiting. Designers must carefully consider these flow arrangements based on specific application requirements and desired performance outcomes.

Fouling Prevention: Fouling refers to the accumulation of unwanted substances on heat exchange surfaces over time, which can significantly reduce system performance. To mitigate fouling effects, designers incorporate various preventive measures, such as using materials resistant to fouling or incorporating features like turbulators or baffles that disrupt fluid flow and prevent deposition.

Pressure Drop and Effectiveness: The design characteristics of a heat exchanger have a direct impact on its performance factors, such as pressure drop and effectiveness. Pressure drop refers to the decrease in fluid pressure as it flows through the exchanger. Designers aim to minimize pressure drop to maintain efficient fluid flow and reduce energy consumption. Effectiveness, on the other hand, measures how well a heat exchanger transfers heat between fluids. It is influenced by factors like surface area, flow arrangement, and fouling prevention measures.

By carefully considering these design aspects, engineers can optimize heat transfer efficiency and overall system performance, ensuring that the heat exchanger meets the specific requirements of the application.

Strategies for Maximizing Air-Cooled Heat Exchanger Efficiency

To maximize energy efficiency and get the most out of your air-cooled heat exchangers, there are a few key strategies you can employ:

Ensure Proper Insulation

Proper insulation is crucial for minimizing heat loss or gain from the surroundings, allowing for more effective heat transfer within the system. By using high-quality insulation materials and sealing any gaps or leaks, you can reduce energy wastage and improve overall performance.

Implement Effective Temperature Control

Maintaining optimal temperatures for both the hot and cold fluids involved in the heat exchange process is essential. By carefully monitoring and adjusting these temperatures as needed, you can enhance heat transfer efficiency and prevent unnecessary energy consumption.

Optimize Flow Rates

Optimizing the flow rates within your heat exchanger system is another crucial factor in maximizing efficiency. The flow rate refers to the speed at which the fluids pass through the exchanger. It’s essential to find a balance between too slow (inefficient) and too fast (ineffective). By optimizing flow rates based on factors such as working fluids, pressure differentials, and desired heat transfer rates, you can achieve better energy utilization and improved overall performance.

Implement Comprehensive Monitoring

Regular monitoring is key to identifying potential issues early on before they escalate into larger problems. Implementing a comprehensive monitoring plan allows you to track variables such as temperature differentials, pressure drops, fouling levels, and fluid characteristics. By staying vigilant with monitoring techniques, you can detect any deviations from normal operation promptly and address them through maintenance or repairs to prevent further degradation of heat transfer efficiency.

By implementing these strategies, including proper insulation, effective temperature control, flow rate optimization, and regular monitoring, you can significantly improve the energy efficiency of your air-cooled heat exchanger system, leading to cost savings and environmental benefits.

Maintaining Optimal Heat Exchanger Performance Through Proactive Maintenance

To ensure the optimal performance and longevity of heat exchangers, routine cleaning, inspection, and maintenance procedures are crucial. Regularly cleaning the heat exchanger tubes and surfaces helps prevent the buildup of contaminants such as dirt, debris, and sediment that can hinder heat transfer.

Inspecting the heat exchanger for any signs of fouling, corrosion, or scaling is equally important. Fouling occurs when deposits accumulate on the heat transfer surfaces over time, reducing efficiency. Corrosion can lead to structural damage and leaks in the exchanger. Scaling refers to the formation of mineral deposits due to hard water or other impurities. These issues should be addressed promptly to avoid further damage.

Non-destructive testing (NDT) methods play a vital role in assessing the integrity of heat exchangers without causing any damage to their structure or functionality. These techniques allow technicians to inspect internal components for defects or abnormalities without disassembling them. Common NDT methods include visual inspection, ultrasonic testing, radiographic examination, magnetic particle testing, and dye penetrant inspection.

By implementing a proactive approach towards maintenance, including regular cleaning, inspection, and the use of non-destructive testing methods, heat exchanger owners and operators can identify and address issues early on, maximizing the efficiency and longevity of these critical components.

Selecting the Appropriate Heat Exchanger for Your Needs

Selecting the appropriate heat exchanger for your specific needs requires careful consideration of several factors. These include the temperature range, fluid compatibility, pressure requirements, and space limitations.

When determining the temperature range, you need to establish the minimum and maximum temperatures that your heat exchanger will encounter. Some heat exchangers are better suited for high-temperature applications, while others excel at handling low-temperature fluids.

Fluid compatibility is another crucial factor. Different heat exchangers are designed to work with specific types of fluids, such as water, oil, or corrosive chemicals. It’s essential to choose a heat exchanger that can effectively transfer heat without causing any damage or contamination to the fluid.

Pressure requirements should also be taken into account. Some applications involve high-pressure environments where a robust and durable heat exchanger is necessary. On the other hand, lower pressure systems may allow for more lightweight and cost-effective options.

Finally, space limitations play a role in selecting the right heat exchanger. Depending on your available space, you may need to consider compact designs or explore alternative configurations that can fit within your constraints.

When comparing different types of heat exchangers, consider factors such as thermal efficiency, cost-effectiveness (including initial investment and operating costs), ease of maintenance (accessibility for cleaning and repairs), and compatibility with your specific application requirements.

By carefully evaluating these key factors, you can make an informed decision and select the heat exchanger