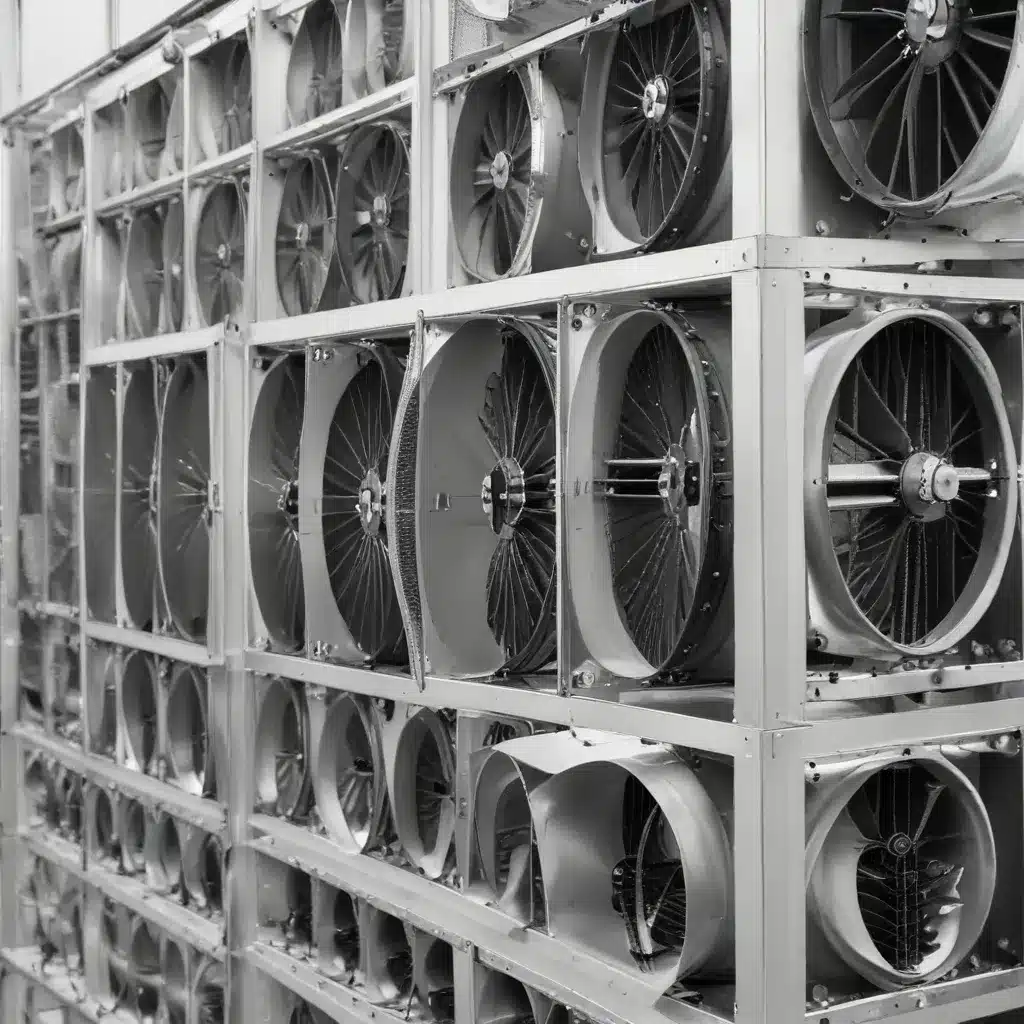

In today’s industrial landscape, efficient cooling solutions are more essential than ever. Among the various methods, air-cooled heat exchangers (ACHEs) stand out as vital components in maintaining the thermal balance of industrial equipment and processes. These robust and versatile devices play a pivotal role in transferring heat between different mediums, ensuring optimal operating conditions, reducing downtime, and extending the lifespan of machinery.

The Importance of Air-Cooled Heat Exchangers in Industrial Cooling

Industrial environments generate significant amounts of heat, which can adversely affect the performance and longevity of critical equipment. By incorporating air-cooled heat exchangers into cooling systems, industries can maintain optimal operating temperatures, enhance energy efficiency, and minimize the environmental impact of their operations.

These heat exchangers work by facilitating the transfer of thermal energy between two fluids without their direct mixing. As the fluids circulate on either side of a conductive surface, typically made of metal, heat is transferred from the hotter fluid to the cooler one through conduction, convection, or radiation, depending on the exchanger’s design.

This heat exchange process results in temperature adjustments on both sides, achieving the desired heating or cooling effect. Air-cooled heat exchangers excel in applications where water availability or cost is a concern, as they utilize air as the cooling medium, eliminating the need for extensive water-based cooling systems.

Maximizing Heat Transfer Efficiency Through Optimal Design

Achieving optimal energy efficiency and reliability in air-cooled heat exchanger design requires a deep understanding of the fundamental principles of heat transfer. There are three primary mechanisms at play:

- Conduction: Heat transfer through direct contact between the fluids and the solid surfaces within the heat exchanger.

- Convection: Heat transfer facilitated by the movement of the fluids, both on the inside and outside of the heat exchanger.

- Radiation: Heat transfer through electromagnetic waves emitted by the heat exchanger’s surfaces.

By selecting the right type of air-cooled heat exchanger and designing the system to maximize conduction and convection, industries can achieve efficient and reliable cooling. Some of the key design considerations include:

- Fin Design: The shape, density, and material of the fins play a crucial role in enhancing air-side heat transfer. Optimizing fin geometry and surface area can significantly improve thermal performance.

- Tube Configuration: The arrangement and spacing of the heat exchanger tubes, as well as their diameter and wall thickness, can impact heat transfer rates and pressure drop.

- Airflow Optimization: Ensuring efficient airflow through the heat exchanger, either through natural convection or forced airflow, is essential for maximizing heat dissipation.

- Material Selection: Choosing the right materials for the heat exchanger’s construction, such as copper, aluminum, or stainless steel, can enhance corrosion resistance, durability, and thermal conductivity.

By carefully considering these design elements, engineers can create air-cooled heat exchangers that deliver superior heat transfer performance and energy savings.

Types of Air-Cooled Heat Exchangers

Air-cooled heat exchangers come in a variety of configurations, each with its own advantages and applications. Some of the most common types include:

-

Fin-Tube Heat Exchangers: These feature a series of finned tubes that facilitate heat transfer between the air and the fluid flowing through the tubes. They are widely used in HVAC systems, refrigeration, and industrial cooling applications.

-

Microchannel Heat Exchangers: Characterized by their compact, high-efficiency design, microchannel heat exchangers utilize small, parallel fluid channels to maximize the surface area for heat transfer. They are commonly found in automotive air conditioning systems and certain industrial applications.

-

Plate-Fin Heat Exchangers: In this design, the heat transfer surface consists of a series of thin metal plates with corrugated fins in between. This configuration maximizes the surface area for effective heat dissipation, making them suitable for applications with high heat loads, such as power generation and petrochemical processing.

-

Hybrid Heat Exchangers: These combine the benefits of air-cooled and water-cooled designs, utilizing both air and water as the cooling media. This hybrid approach can offer enhanced performance and flexibility in applications where water resources are limited or where precise temperature control is required.

The selection of the appropriate air-cooled heat exchanger type depends on factors such as the specific cooling requirements, available space, fluid properties, and energy efficiency considerations. By understanding the unique strengths of each design, engineers can optimize the heat exchanger selection to meet the unique needs of their industrial processes.

Optimizing Air-Cooled Heat Exchanger Performance

To ensure the long-term efficiency and reliability of air-cooled heat exchangers, it is essential to implement best practices for maintenance and optimization. Here are some key strategies:

-

Regular Cleaning and Inspection: Regularly clean the heat exchanger’s fins and tubes to remove any buildup of dust, debris, or contaminants that can impede airflow and reduce heat transfer efficiency. Inspect for signs of corrosion, fouling, or physical damage, and address any issues promptly.

-

Airflow Management: Ensure that the heat exchanger’s airflow is unobstructed, with no blockages or restrictions that could impair the cooling performance. Consider installing fans or baffles to optimize the air circulation patterns for maximum heat dissipation.

-

Fouling Prevention: Implement strategies to mitigate fouling, such as using filters, water treatment, or regular cleaning schedules. Fouling can significantly reduce the heat exchanger’s efficiency and increase energy consumption over time.

-

Monitoring and Optimization: Regularly monitor the heat exchanger’s performance, measuring parameters such as inlet and outlet temperatures, pressure drops, and energy consumption. Use this data to identify opportunities for optimization, such as adjusting fan speeds, modifying the fin design, or considering upgrades to more efficient models.

-

Proactive Maintenance: Establish a comprehensive maintenance program, including routine inspections, preventive maintenance, and prompt response to any malfunctions or issues. This approach can help extend the lifespan of the heat exchanger, minimize downtime, and ensure consistent, reliable cooling performance.

By diligently implementing these optimization strategies, industries can maximize the efficiency, energy savings, and longevity of their air-cooled heat exchangers, leading to enhanced overall system performance and reduced environmental impact.

Embracing the Future of Air-Cooled Heat Exchanger Technology

The field of air-cooled heat exchanger technology is continuously evolving, driven by the demand for more efficient, sustainable, and innovative cooling solutions. Some emerging trends and advancements to watch for include:

-

Improved Fin and Tube Designs: Ongoing research and development in areas such as nano-structured surfaces, micro-channel configurations, and advanced materials are leading to heat exchangers with higher heat transfer coefficients and lower pressure drops.

-

Adaptive Cooling Systems: The integration of smart sensors, advanced controls, and predictive analytics can enable air-cooled heat exchangers to dynamically adjust their operation based on changing load conditions, weather patterns, or process requirements, optimizing energy efficiency and heat dissipation.

-

Hybrid Cooling Approaches: The combination of air-cooled and water-cooled technologies, as mentioned earlier, is expected to gain traction, particularly in applications where water scarcity or cost is a concern, yet precise temperature control is essential.

-

Renewable Energy Integration: As industries strive to reduce their carbon footprint, air-cooled heat exchangers are being increasingly paired with renewable energy sources, such as solar or wind power, to create sustainable, self-sufficient cooling systems.

-

Additive Manufacturing: The adoption of 3D printing and other additive manufacturing techniques is allowing for the creation of highly customized, complex heat exchanger designs that can further enhance heat transfer performance and energy efficiency.

By staying informed about these emerging trends and advancements, industries can position themselves to capitalize on the latest innovations in air-cooled heat exchanger technology, ensuring they remain at the forefront of efficient and sustainable cooling solutions.

Conclusion

Air-cooled heat exchangers play a vital role in industrial cooling, contributing to enhanced energy efficiency, reduced environmental impact, and improved equipment reliability. By understanding the principles of heat transfer, selecting the right type of heat exchanger, and implementing best practices for maintenance and optimization, industries can unlock the full potential of these versatile devices.

As the demand for sustainable and efficient cooling solutions continues to grow, the future of air-cooled heat exchanger technology holds exciting possibilities. By embracing the latest advancements and trends, industries can stay ahead of the curve, positioning themselves for long-term success and environmental responsibility.

To learn more about how https://www.aircooledheatexchangers.net/ can help you optimize your air-cooled heat exchanger performance and unlock new levels of efficiency, contact us today. Our team of experts is dedicated to providing tailored solutions and industry-leading insights to meet your unique cooling challenges.