The Importance of Effective Thermal Management in Automotive Electronics

In the fast-paced world of the automotive industry, the demand for advanced electronics and sophisticated powertrain technologies has never been greater. From engine control modules and navigation systems to hybrid and electric vehicle components, these electronic systems are integral to the performance, efficiency, and safety of modern vehicles. However, as these electronic devices become increasingly complex and power-dense, they also generate significant amounts of heat that can compromise their reliability and longevity if not properly managed.

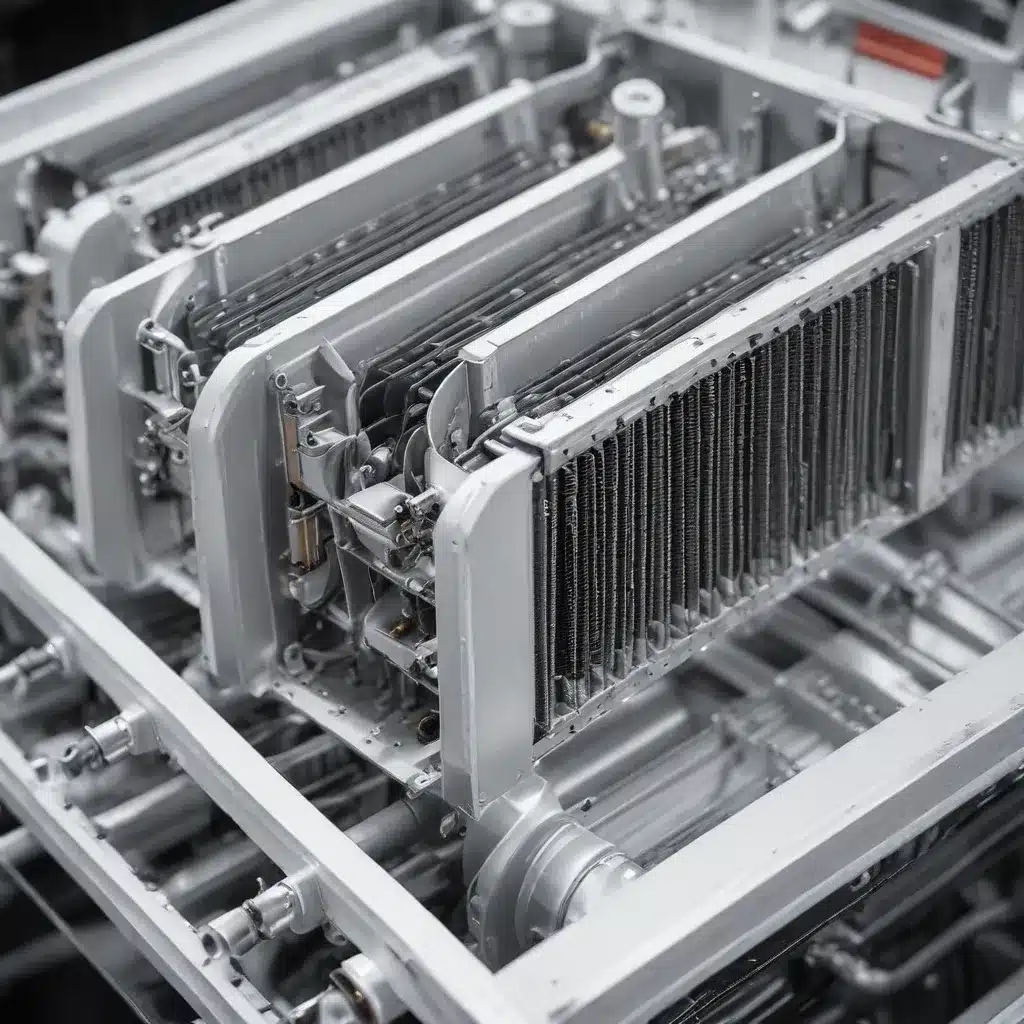

Effective thermal management is crucial in the automotive industry to ensure that critical electronic components operate within their optimal temperature range, maintaining peak performance and avoiding potential failures or premature degradation. This is where air-cooled heat exchangers play a pivotal role, providing a robust and efficient solution for dissipating the heat generated by these electronic systems.

Designing Air-Cooled Heat Exchangers for Automotive Applications

Air-cooled heat exchangers are a popular choice for thermal management in the automotive industry due to their compact size, lightweight construction, and ability to effectively transfer heat from electronic components to the surrounding air. To optimize the design of these heat exchangers for automotive applications, engineers must consider a range of factors, including:

Compact and Lightweight Construction

Automotive systems require highly compact and lightweight thermal management solutions to minimize the impact on vehicle weight, aerodynamics, and overall packaging. Air-cooled heat exchangers can be designed with innovative fin and tube configurations, such as pin-fin heat sinks, to maximize heat transfer while maintaining a small footprint and reduced mass.

Enhanced Heat Transfer Capabilities

The performance of an air-cooled heat exchanger is directly related to its ability to efficiently transfer heat from the electronic components to the surrounding air. Factors such as fin density, fin geometry, and airflow patterns can be optimized to enhance heat transfer and maximize the cooling capacity of the heat exchanger.

Durability and Reliability

Automotive components must operate reliably under challenging conditions, including exposure to vibrations, extreme temperatures, and contaminants. Air-cooled heat exchangers for automotive applications must be designed with durable materials and robust construction to withstand these demanding environments and ensure long-term, maintenance-free operation.

Integrated Design and Packaging

Integrating air-cooled heat exchangers seamlessly into the overall vehicle design is crucial for optimal performance and efficient use of available space. This may involve collaborative efforts between heat exchanger manufacturers and automotive OEMs to develop customized solutions that meet specific packaging and functional requirements.

Automotive Applications of Air-Cooled Heat Exchangers

Air-cooled heat exchangers find widespread applications in the automotive industry, addressing the thermal management needs of various electronic systems and components:

Powertrain Electronics

Modern vehicles rely on a range of powertrain electronics, such as engine control modules, transmission control units, and hybrid/electric drivetrain components. These systems generate significant amounts of heat during operation, which must be effectively dissipated to maintain optimal performance and reliability. Air-cooled heat exchangers are commonly used to cool these critical powertrain electronics, ensuring efficient and reliable vehicle operation.

Vehicle Infotainment and Electronics

The increasing integration of advanced infotainment systems, navigation units, and other electronic features in vehicles requires efficient thermal management solutions. Air-cooled heat exchangers can be designed to dissipate the heat generated by these electronic systems, preventing overheating and ensuring uninterrupted functionality.

Electric and Hybrid Vehicle Thermal Management

As the automotive industry continues its transition towards electrification, the importance of effective thermal management has become even more critical. Air-cooled heat exchangers play a crucial role in cooling the high-power electronic components, such as inverters, converters, and battery packs, found in electric and hybrid vehicles. Proper thermal management helps maintain the optimal operating temperatures of these critical systems, enhancing their performance, efficiency, and lifespan.

Exhaust Gas Recirculation (EGR) Coolers

Exhaust Gas Recirculation (EGR) coolers are essential components in both diesel and gasoline engines, as they help reduce nitrogen oxide (NOx) emissions and improve fuel economy. Air-cooled heat exchangers are often used in EGR cooler designs to efficiently dissipate the heat from the recirculated exhaust gas, enabling the EGR system to function effectively.

Charge-Air Coolers (CACs)

Charge-Air Coolers (CACs) are another critical component in modern engines, particularly those with turbochargers or superchargers. These heat exchangers are responsible for cooling the hot, high-pressure intake air before it enters the engine, improving volumetric efficiency and reducing emissions. Air-cooled CACs leveraging innovative fin and tube designs can provide compact, lightweight, and highly efficient cooling solutions for automotive applications.

Maintenance and Performance Optimization of Air-Cooled Heat Exchangers

To ensure the long-term reliability and optimal performance of air-cooled heat exchangers in automotive applications, proper maintenance and performance optimization strategies are crucial. Some key considerations include:

Regular Inspection and Cleaning

Periodic inspection and cleaning of air-cooled heat exchangers are essential to maintain their thermal efficiency. Accumulation of debris, such as dirt, dust, or insects, can obstruct airflow and reduce the heat transfer capabilities of the heat exchanger. A well-designed maintenance plan, including regular cleaning and inspection, can help prevent performance degradation and extend the lifespan of the heat exchanger.

Airflow Optimization

The effectiveness of an air-cooled heat exchanger is heavily dependent on the airflow patterns and velocities across the heat transfer surfaces. Factors such as fan performance, duct design, and air inlet/outlet configurations can be optimized to ensure efficient airflow and maximize heat transfer rates.

Material and Corrosion Resistance

The selection of durable, corrosion-resistant materials is critical for air-cooled heat exchangers in automotive applications, where they may be exposed to harsh environmental conditions, such as moisture, salt, and chemicals. Utilizing materials like aluminum, stainless steel, or specially coated heat exchanger components can help improve the long-term reliability and performance of these thermal management solutions.

Thermal Performance Monitoring

Continuous monitoring of the thermal performance of air-cooled heat exchangers can help identify any degradation or changes in their efficiency over time. By tracking key parameters, such as inlet and outlet temperatures, pressure drops, and overall heat transfer rates, maintenance schedules can be optimized, and potential issues can be detected and addressed proactively.

Conclusion: Unlocking the Potential of Air-Cooled Heat Exchangers in Automotive Thermal Management

As the automotive industry continues to push the boundaries of electronic integration, thermal management has become a critical challenge that must be addressed. Air-cooled heat exchangers, with their versatility, efficiency, and durability, are well-positioned to play a pivotal role in meeting these thermal management demands in the automotive sector.

By optimizing the design, materials, and maintenance strategies of air-cooled heat exchangers, automotive manufacturers and OEMs can unlock the full potential of these thermal management solutions, ensuring the reliable and efficient operation of their electronic systems. As the industry continues to evolve, the importance of effective thermal management will only grow, making air-cooled heat exchangers an indispensable component in the future of automotive technology.

For more information on how Air Cooled Heat Exchangers can help you address your automotive thermal management needs, please don’t hesitate to reach out to our team of experts.