Mastering the Art of Efficient Heat Transfer in HVAC Applications

In the dynamic and ever-evolving world of HVAC systems, optimizing heat transfer performance is crucial for achieving energy efficiency, reliable operation, and enhanced user comfort. At the heart of this challenge lies the air-cooled heat exchanger, an essential component that plays a pivotal role in the thermal management of these systems. As a seasoned expert in the field, I’m excited to share practical insights and in-depth knowledge to help you unlock the full potential of air-cooled heat exchanger design.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

Air-cooled heat exchangers, as the name suggests, utilize air as the cooling medium to dissipate heat from a process or system. These heat exchangers work by facilitating the transfer of thermal energy between two fluids – typically a hot process fluid and a cooler airstream – without the fluids coming into direct contact. The heat is transferred through a series of heat transfer mechanisms, including conduction, convection, and radiation, depending on the specific design of the heat exchanger.

The performance of an air-cooled heat exchanger is largely determined by the efficiency of these heat transfer processes, which are influenced by factors such as the heat exchanger’s surface area, fin design, airflow patterns, and the properties of the fluids involved. Optimizing these parameters is crucial for achieving the desired heating or cooling effect in HVAC applications, where precise temperature control and energy-efficient operation are paramount.

Innovative Designs for Enhanced Thermal Performance

To meet the evolving demands of modern HVAC systems, manufacturers have introduced a range of innovative air-cooled heat exchanger designs that offer superior thermal management capabilities. Let’s explore some of these cutting-edge solutions:

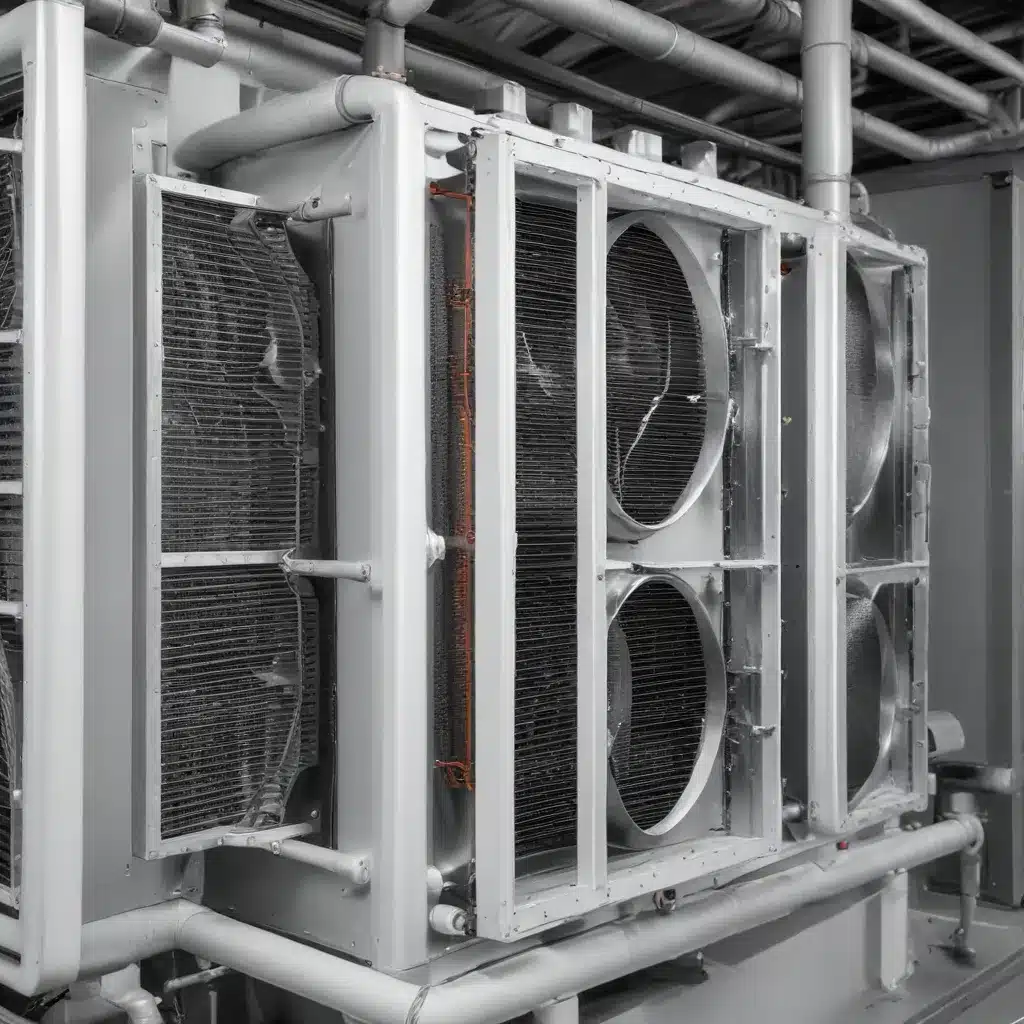

Finned Tube Heat Exchangers: These heat exchangers feature a series of metal tubes with extended surface area in the form of fins. The fins, typically made of aluminum or copper, increase the effective surface area for heat transfer, allowing for more efficient cooling or heating of the process fluid. By carefully optimizing the fin design, spacing, and material, manufacturers can enhance the overall heat transfer coefficient and improve the thermal performance of the system.

Microchannel Heat Exchangers: Microchannel heat exchangers represent a more compact and efficient alternative to traditional finned tube designs. These heat exchangers utilize small, parallel microchannels to distribute the process fluid, resulting in a larger surface area-to-volume ratio and improved heat transfer characteristics. The reduced size and weight of microchannel heat exchangers make them well-suited for applications with space constraints, such as rooftop HVAC units or compact commercial systems.

Hybrid Heat Exchangers: Hybrid heat exchangers combine the benefits of both air-cooled and liquid-cooled designs, offering enhanced thermal management capabilities. These heat exchangers incorporate both air-side and liquid-side heat transfer surfaces, allowing for the simultaneous cooling or heating of multiple fluid streams. This versatility makes hybrid heat exchangers an attractive choice for applications where a single heat exchanger needs to handle diverse thermal loads or process requirements.

Phase Change Materials (PCM) Integrated Heat Exchangers: Innovative air-cooled heat exchangers are now integrating phase change materials (PCMs) to enhance their thermal storage and energy-saving capabilities. PCMs, such as paraffin waxes or salt hydrates, can absorb and release large amounts of latent heat during their phase transitions, effectively smoothing out fluctuations in thermal loads and improving the overall efficiency of the HVAC system.

By understanding the unique advantages of these advanced heat exchanger designs, HVAC system designers can select the most appropriate solution to meet the specific thermal management needs of their applications, whether it’s optimizing energy efficiency, improving occupant comfort, or addressing space constraints.

Optimizing Air-Cooled Heat Exchanger Performance

Achieving optimal performance from an air-cooled heat exchanger requires a comprehensive understanding of the key design parameters and their interplay. Let’s dive into the critical factors that contribute to enhanced thermal management in HVAC systems:

Airflow Optimization: Ensuring efficient airflow is essential for maximizing heat transfer in an air-cooled heat exchanger. Factors such as fan selection, duct design, and airflow distribution can significantly impact the heat exchanger’s effectiveness. Computational Fluid Dynamics (CFD) simulations can help identify and address any potential airflow bottlenecks or recirculation zones, ultimately improving the overall heat transfer performance.

Fin Design and Geometry: The fin design, including the size, spacing, and shape, plays a crucial role in enhancing the surface area available for heat transfer. Optimizing the fin geometry can lead to increased heat transfer coefficients, reduced pressure drops, and improved overall thermal efficiency. Advanced fin designs, such as wavy or louvered fins, can further improve airside heat transfer by promoting turbulent airflow and disrupting the boundary layer.

Material Selection: The choice of materials for the heat exchanger’s construction can significantly impact its performance and durability. Aluminum and copper are commonly used due to their high thermal conductivity, corrosion resistance, and cost-effectiveness. However, emerging materials, such as advanced aluminum alloys or composite materials, can offer enhanced thermal and mechanical properties, further improving the heat exchanger’s efficiency and lifespan.

Maintenance and Fouling Prevention: Proper maintenance and cleaning of air-cooled heat exchangers are essential for maintaining their optimal performance over time. Fouling, caused by the buildup of dirt, dust, or other contaminants on the heat transfer surfaces, can significantly impair the heat exchanger’s efficiency. Implementing regular cleaning protocols and incorporating design features that minimize fouling, such as self-cleaning mechanisms or easy access for maintenance, can help ensure the long-term reliable operation of the HVAC system.

By meticulously optimizing these design parameters, HVAC system designers can unlock the full potential of air-cooled heat exchangers, delivering enhanced thermal management, energy efficiency, and reliable operation for their clients.

Emerging Trends and Future Developments

As the HVAC industry continues to evolve, the landscape of air-cooled heat exchanger technology is also undergoing exciting transformations. Here are some emerging trends and future developments that are shaping the future of thermal management in HVAC systems:

Hybrid and Integrated Cooling Solutions: The integration of air-cooled heat exchangers with other cooling technologies, such as evaporative cooling, thermal energy storage, or heat pump systems, is gaining traction. These hybrid solutions leverage the strengths of different cooling mechanisms to create more versatile, energy-efficient, and resilient HVAC systems capable of addressing a wider range of climate conditions and load profiles.

Digitalization and Smart Controls: The advent of the Internet of Things (IoT) and advances in digital control systems are transforming the way air-cooled heat exchangers are monitored and optimized. By incorporating smart sensors, predictive analytics, and advanced control algorithms, HVAC systems can automate the optimization of heat exchanger performance, adjusting parameters like airflow, fan speed, and refrigerant charge in real-time to maintain peak efficiency.

Sustainable and Eco-friendly Designs: Driven by the global push for sustainability, air-cooled heat exchanger manufacturers are increasingly focusing on developing environmentally friendly solutions. This includes the use of refrigerants with lower global warming potential, the incorporation of renewable or recycled materials, and the optimization of energy consumption through advanced heat recovery techniques.

Additive Manufacturing and Customization: The rise of additive manufacturing, or 3D printing, is enabling the creation of air-cooled heat exchangers with unprecedented design flexibility and customization. This technology allows for the development of complex, optimized fin geometries, tailored to the specific thermal management requirements of individual HVAC applications, further enhancing the efficiency and performance of these critical components.

As the HVAC industry continues to evolve, the role of air-cooled heat exchangers will become increasingly crucial in driving energy efficiency, sustainability, and user comfort. By staying abreast of these emerging trends and embracing innovative design approaches, HVAC system designers can position themselves at the forefront of thermal management solutions, delivering cutting-edge technology to their clients.

Conclusion

In the dynamic world of HVAC systems, air-cooled heat exchangers play a pivotal role in ensuring efficient thermal management, energy conservation, and reliable operation. By delving into the latest advancements in heat exchanger design, material selection, and optimization strategies, HVAC professionals can unlock the full potential of these essential components and deliver exceptional performance to their clients.

Whether it’s implementing innovative finned tube designs, leveraging the advantages of microchannel technology, or integrating phase change materials, the opportunities for enhancing air-cooled heat exchanger performance are vast. By understanding the critical design factors and embracing emerging trends, HVAC system designers can stay ahead of the curve, creating tailored solutions that address the evolving needs of the industry.

As an expert in the field of air-cooled heat exchangers, I encourage you to explore the resources available on the Air Cooled Heat Exchangers website. Here, you can delve deeper into the latest advancements, access technical guides, and connect with industry professionals to further enhance your understanding of this essential HVAC technology. Together, we can push the boundaries of thermal management and create sustainable, energy-efficient HVAC systems that deliver unparalleled comfort and performance.