In the rapidly evolving landscape of industrial operations, the importance of air-cooled heat exchangers has become increasingly paramount. As facilities strive to optimize efficiency, enhance sustainability, and comply with stringent environmental regulations, the design and engineering of these critical components have taken center stage. Amidst this shifting landscape, one area that demands heightened attention is the optimization of air-cooled heat exchanger design to ensure compliance with emerging standards and directives related to noise emissions and acoustic performance.

Navigating the Noise Challenge in Industrial Environments

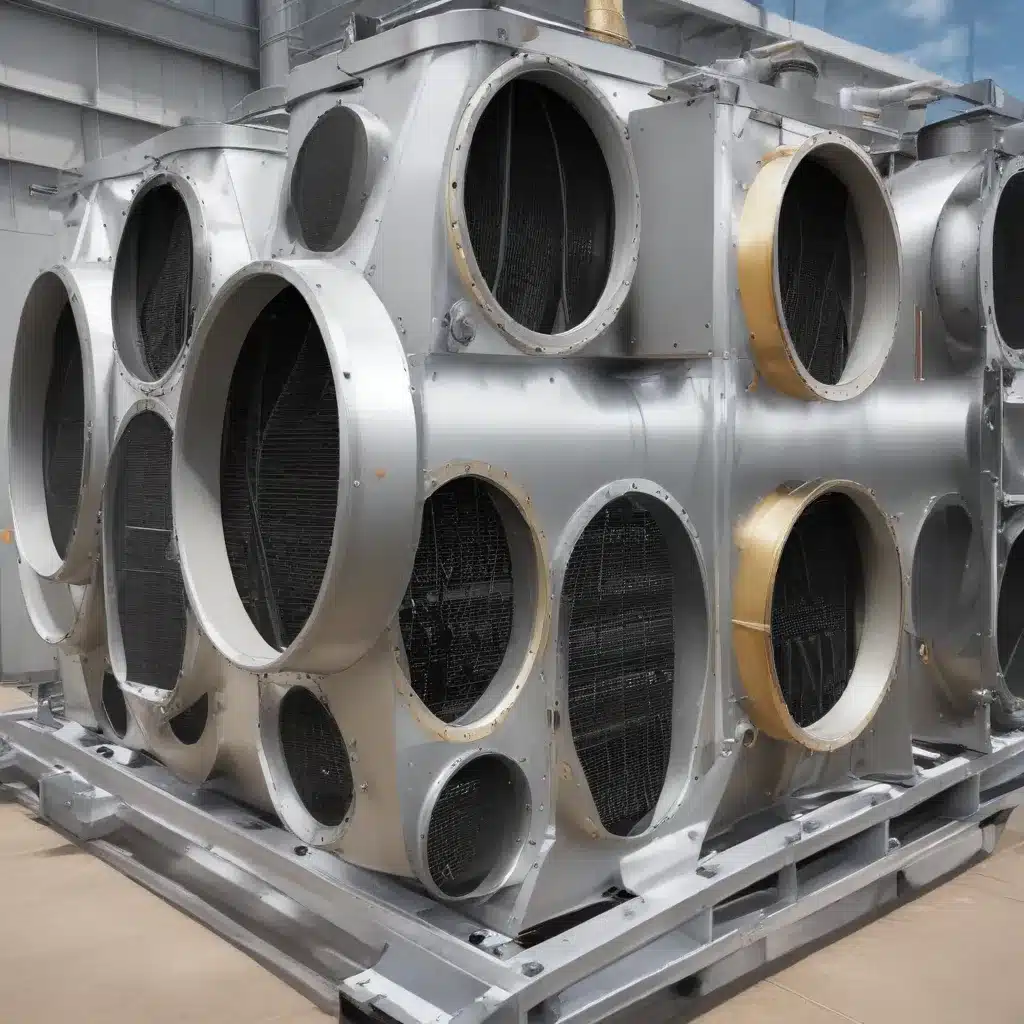

Industrial facilities, from manufacturing plants to data centers, are inherently noisy environments. The constant hum of machinery, the whirring of cooling fans, and the vibrations of various equipment all contribute to a cacophony of sounds that can significantly impact the well-being of workers and the surrounding community. Air-cooled heat exchangers, in particular, are often a primary source of noise, as their efficient operation relies on the continuous operation of high-speed fans.

Decibel Levels and Noise Spectra: Measurements of noise levels in industrial settings often reveal decibel (dB) readings in the range of 90 dB(A) or higher, particularly in close proximity to air-cooled heat exchangers. Moreover, the noise spectrum produced by these heat exchangers encompasses a broad range, including low-frequency vibrations that can be particularly challenging to mitigate. Prolonged exposure to such noise levels can lead to a range of health issues, from temporary hearing impairment to long-term hearing loss.

Regulatory Compliance and Community Impact: The detrimental effects of industrial noise pollution have not gone unnoticed, and regulatory bodies worldwide have implemented increasingly stringent guidelines and directives to address this concern. The International Finance Corporation (IFC) General Environmental, Health, and Safety (EHS) Guidelines, for instance, stipulate noise level limits both within the workplace and in surrounding communities. Failure to comply with these regulations can result in costly fines, reputational damage, and, in some cases, the suspension of operations.

Strategies for Optimizing Air-Cooled Heat Exchanger Design

To navigate the complex landscape of noise emissions and acoustic performance in industrial applications, air-cooled heat exchanger manufacturers and designers must adopt a comprehensive approach that addresses the issue at its core. This multi-faceted strategy encompasses a range of design considerations, technological advancements, and operational best practices.

Innovative Design Approaches

Soundproofing and Acoustic Dampening: One of the most effective strategies for mitigating noise from air-cooled heat exchangers is the incorporation of soundproofing and acoustic dampening measures into the design. This can involve the use of sound-absorbing materials, such as acoustic foam or rubberized coatings, within the heat exchanger casing and surrounding structures. Strategic placement of these materials can help to contain and absorb sound waves, reducing the overall noise output.

Optimized Fan and Motor Design: The selection and configuration of fans and motors within air-cooled heat exchangers play a crucial role in their acoustic performance. Replacing standard fans with quieter models, optimizing fan speed based on thermal demand, and implementing variable-speed drives can significantly reduce the noise generated by these critical components.

Immersion and Hybrid Cooling Techniques: Emerging cooling technologies, such as immersion cooling and hybrid systems that combine air cooling with more efficient liquid-based methods, offer promising solutions for reducing noise levels. By eliminating the need for multiple high-speed fans, these innovative approaches can dramatically lower the overall sound output of air-cooled heat exchangers.

Operational Strategies

Noise Monitoring and Measurement: Effective management of noise in industrial settings requires a comprehensive approach to monitoring and measuring sound levels. Implementing dosimetry, a method of assessing employee noise exposure, and conducting regular noise assessments can help identify areas of concern and guide the implementation of targeted mitigation strategies.

Hearing Protection and Employee Well-being: Safeguarding the health and well-being of employees working in proximity to air-cooled heat exchangers is of paramount importance. Providing appropriate hearing protection equipment, such as earplugs or noise-cancelling headphones, and ensuring regular hearing health checks can help minimize the risk of hearing-related issues.

Energy-Efficient Operations: The energy consumption of air-cooled heat exchangers can have a direct impact on their noise output, as higher energy usage often correlates with increased fan speeds and more pronounced mechanical noise. By optimizing energy consumption through strategies like fan speed control and the adoption of energy-efficient technologies, industrial facilities can simultaneously reduce noise levels and improve overall operational efficiency.

Embracing the Future of Air-Cooled Heat Exchanger Design

As the industrial landscape continues to evolve, the optimization of air-cooled heat exchanger design to address noise emissions and acoustic performance is poised to become an increasingly critical area of focus. Technological advancements, regulatory changes, and heightened environmental awareness are driving the industry towards a future where sustainable, quiet, and compliant heat exchanger solutions are the norm.

Emerging Trends and Innovations

Advancements in Soundproofing Materials: Ongoing research and development in the field of acoustic materials are leading to the creation of more effective and innovative sound-dampening solutions. From advanced acoustic foams to smart, adaptive materials that can respond to changing noise conditions, these technological breakthroughs hold the potential to revolutionize the way air-cooled heat exchangers are designed and engineered.

Integrated Noise Management Systems: The integration of sophisticated noise monitoring and control systems within air-cooled heat exchanger designs is an emerging trend. These smart systems can dynamically adjust fan speeds, optimize airflow, and deploy targeted sound-absorbing measures in real-time, ensuring compliance with evolving noise regulations and community expectations.

Modular and Scalable Designs: Innovative data center designs, which often incorporate air-cooled heat exchangers, have paved the way for the adoption of modular and scalable solutions in industrial settings. These approaches integrate noise management considerations into the overall design, creating more harmonious and sustainable facilities that balance functionality with acoustic performance.

Regulatory Landscape and Industry Standards

Evolving Noise Regulations: As the awareness of the environmental and health impacts of industrial noise pollution grows, regulatory bodies worldwide are tightening their guidelines and standards. Compliance with these emerging directives will be a key driver in the design and engineering of air-cooled heat exchangers, pushing manufacturers and designers to prioritize acoustic performance alongside other critical factors.

International Standards and Best Practices: Industry associations and standards organizations are playing a pivotal role in defining best practices and guidelines for managing noise in industrial applications. The development of comprehensive standards, such as those outlined in the IFC General EHS Guidelines, will help to shape the future of air-cooled heat exchanger design and ensure the consistency of acoustic performance across the industry.

Underwater Data Centers and Unique Acoustic Considerations: The emergence of novel approaches, such as underwater data centers, introduces unique acoustic challenges that require specialized design and engineering considerations. These pioneering technologies must comply with distinct noise regulations and environmental impact assessments, further driving innovation in the field of air-cooled heat exchanger design.

By embracing the future of air-cooled heat exchanger design and addressing the critical issue of noise emissions and acoustic performance, industrial facilities can not only ensure compliance with evolving regulations but also cultivate a safer, more sustainable, and more harmonious work environment for their employees and surrounding communities. As the industry continues to evolve, the Air Cooled Heat Exchangers blog remains committed to providing the latest insights, practical guidance, and cutting-edge advancements in this rapidly changing landscape.