The Pivotal Role of Heat Exchangers in Industrial Efficiency

In the vast landscape of industrial processes, the role of heat exchangers stands as a linchpin, facilitating thermal energy transfer to power essential operations across diverse sectors. As integral components of intricate systems, heat exchangers play a pivotal role in enhancing efficiency, reducing costs, and mitigating environmental impact. Their ability to transfer heat between fluids while maintaining separation makes them indispensable in numerous industrial settings, from power generation and chemical processing to HVAC systems.

Consider a power plant where steam turbines generate electricity. Here, heat exchangers facilitate heat transfer from the combustion process to water, producing steam that drives turbines. Similarly, precise temperature control is achieved in chemical manufacturing through intricately designed heat exchangers, optimizing reaction rates and product quality. Beyond their role in individual processes, the collective impact of energy-efficient heat exchangers reverberates across industries, contributing to substantial cost savings and environmental sustainability.

As global concerns about climate change escalate, reducing energy consumption becomes a paramount objective. By maximizing energy transfer efficiency, heat exchangers enable industries to achieve optimal performance with minimized resource utilization. This translates to direct cost savings and aligns with the imperative to curtail greenhouse gas emissions associated with excessive energy consumption.

In the subsequent sections, we delve into the intricacies of proper heat exchanger sizing, fluid flow management, thermal design considerations, and a spectrum of strategies aimed at optimizing performance and ensuring longevity through meticulous maintenance practices. The journey toward enhanced energy efficiency and sustainability begins with understanding the nuanced interplay of factors that govern heat exchanger functionality.

Selecting the Right Heat Exchanger Design and Sizing

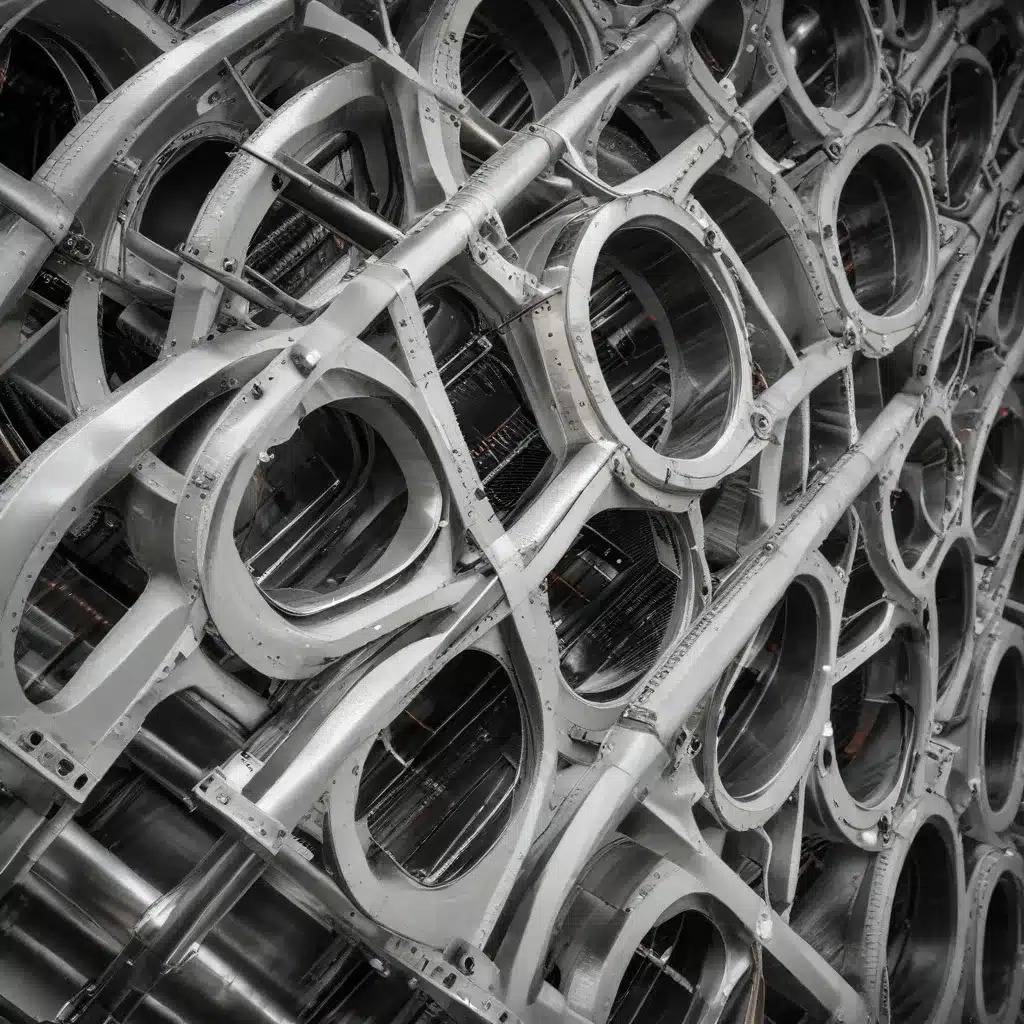

Heat exchangers are versatile instruments of various types, each tailored for specific applications. The efficiency and effectiveness of these devices hinge significantly on proper sizing and meticulous selection. Factors such as fouling tendencies, pressure drops, and material compatibility influence the selection process.

Ensuring optimal fluid flow within a heat exchanger system is a critical aspect that directly influences its efficiency and performance. Achieving uniform distribution and maintaining appropriate flow velocities are key considerations in maximizing heat transfer effectiveness and preventing operational challenges. Computational fluid dynamics (CFD) simulations can model and optimize flow patterns, aiding the design process.

The thermal design of a heat exchanger is a multifaceted process that involves configuring the arrangement of fluid paths and selecting materials to maximize heat transfer efficiency. Counter-flow and crossflow configurations offer distinct advantages, while materials with high thermal conductivity, such as copper and aluminum, facilitate rapid and efficient heat transfer.

Mitigating Fouling and Optimizing Fluid Selection

Fouling, the unwanted accumulation of deposits on heat exchanger surfaces, poses a significant threat to efficiency and performance. Implementing a systematic approach to regular inspections, routine cleaning, and incorporating features like turbulators and enhanced surfaces can help mitigate fouling challenges.

Choosing lubricants and fluids in a heat exchanger system is pivotal in optimizing thermal performance and preventing operational challenges. Fluids with high thermal conductivity facilitate efficient heat transfer, while regular fluid analysis and timely replacements ensure consistent performance. Proper lubrication of mechanical components also contributes to the overall reliability of the heat exchanger system.

Enhancing Energy Efficiency through Insulation and Temperature Control

Efficient insulation is a cornerstone of heat exchanger design, playing a pivotal role in minimizing heat loss and optimizing energy efficiency. The selection of appropriate insulation materials and the application of internal and external insulation layers create a protective thermal envelope, directing the transferred thermal energy toward the intended processes.

Maintaining precise control over temperatures within a heat exchanger system is paramount for optimizing efficiency and ensuring that industrial processes operate at peak performance. Strategies such as utilizing temperature sensors and controllers, as well as implementing variable flow and temperature control systems, contribute to the adaptability and efficiency of heat exchanger operations.

Harnessing Waste Heat and Integrating Advanced Technologies

The concept of heat recovery transforms the role of heat exchangers beyond mere thermal exchange; it positions them as key players in sustainability initiatives. By integrating heat exchangers into preheating systems, cogeneration plants, and dedicated waste heat recovery units, industries can harness waste heat to reduce overall energy consumption and greenhouse gas emissions.

The integration of advanced technologies, particularly Computational Fluid Dynamics (CFD) simulations, is reshaping the optimization and design of heat exchangers. CFD simulations enable a detailed analysis of fluid flow patterns, thermal performance, and overall system behavior, allowing for virtual experimentation and accelerating the iterative design process.

Comprehensive Maintenance Strategies for Sustained Efficiency

Establishing a proactive and comprehensive maintenance schedule is indispensable for sustaining the efficiency and longevity of heat exchanger systems. Regular inspections, routine cleaning, component replacements, and calibration of instruments contribute to consistent energy efficiency and the avoidance of costly repairs.

Maintaining detailed records of maintenance activities and ensuring compliance with industry standards are crucial elements of an effective heat exchanger maintenance program. By integrating these practices, industries can maximize the performance and lifespan of their heat exchange systems.

Conclusion: Embracing Sustainable Thermal Management

In the intricate tapestry of industrial processes, optimizing heat exchangers emerges as a linchpin for achieving efficiency, reducing costs, and embracing sustainable practices. By converging strategies, considerations, and advanced technologies, industries can enhance their operational performance and contribute to a greener and more sustainable future.

As industries continue to evolve, the optimization of heat exchangers stands as a beacon of innovation and efficiency. By implementing these strategies and staying abreast of technological advancements, industries can enhance their thermal management, reduce their environmental footprint, and thrive in a world where sustainability is paramount.

Visit https://www.aircooledheatexchangers.net/ to explore more resources on air-cooled heat exchangers and their critical role in industrial operations.