The Evolving Role of Air-Cooled Heat Exchangers in Industrial Efficiency

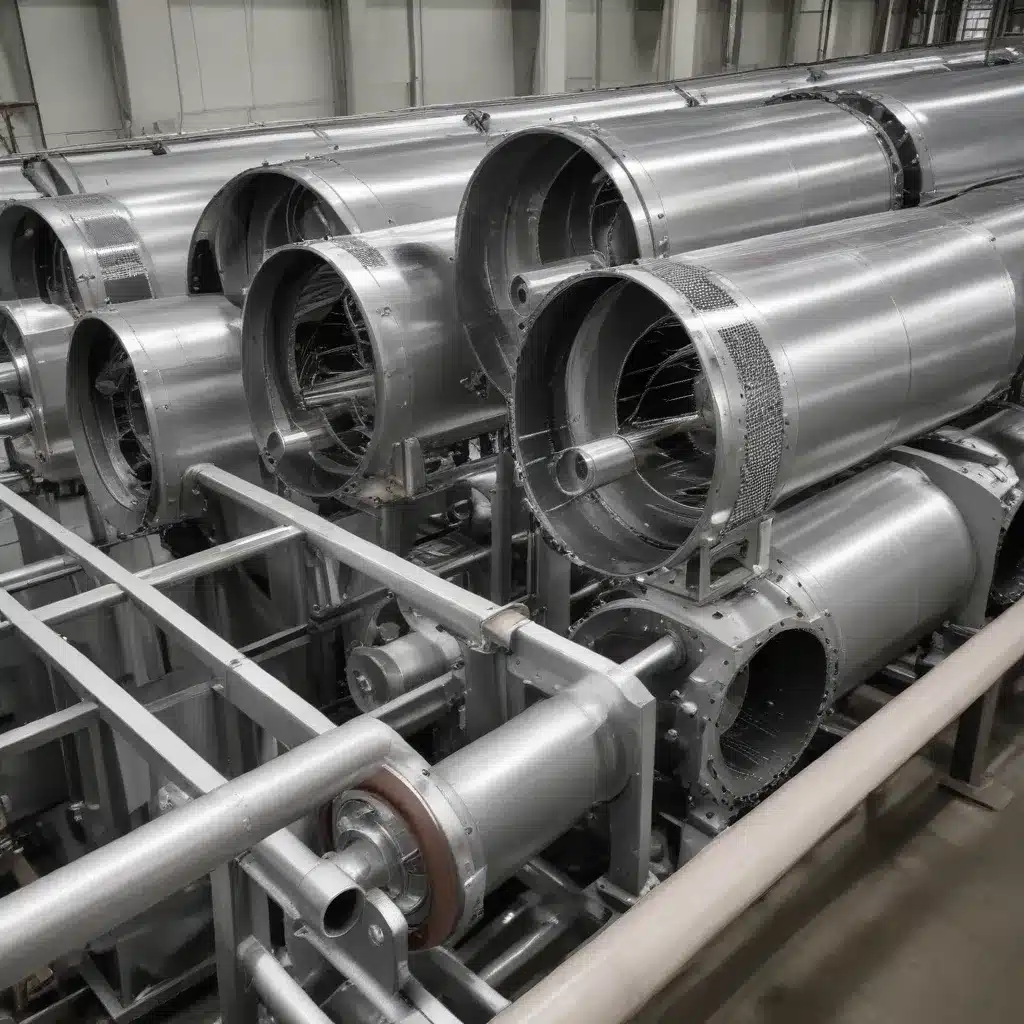

In the ever-changing landscape of industrial processes, the critical role of air-cooled heat exchangers (ACHEs) has become increasingly prominent. These versatile thermal management solutions have transformed the way industries approach efficiency, sustainability, and equipment longevity. As the demand for advanced heat transfer technologies continues to surge, ACHEs have emerged as the linchpin in optimizing industrial operations across a wide array of sectors.

Unleashing the Power of Thermal Management

At the heart of industrial facilities, cooling systems play a critical role in ensuring efficiency and productivity. Among these systems, air-cooled heat exchangers have proven to be invaluable assets, providing reliable and cost-effective heat dissipation solutions. By leveraging the principles of conduction, convection, and radiation, ACHEs facilitate the transfer of thermal energy from hot process fluids or equipment to the surrounding air, effectively maintaining optimal operating temperatures.

Conduction, the transfer of heat through direct contact between materials, forms the foundation of heat exchanger design. The materials used, such as metals with high thermal conductivity, enable the efficient channeling of heat from the source to the heat exchanger’s surface. Convection, the movement of heat through fluids, plays a crucial role in air-cooled heat exchangers. Fans or blowers create airflow, which carries away the heat transferred from the process fluids, dissipating it to the environment. Radiation, the emission of electromagnetic waves, also contributes to the overall heat transfer, albeit to a lesser degree, in ACHEs.

By harnessing these fundamental heat transfer mechanisms, air-cooled heat exchangers have become indispensable in a wide range of industrial applications, including:

- Power generation: Cooling turbines, generators, and other power plant equipment.

- Chemical processing: Regulating temperatures in reactors, distillation columns, and other critical process units.

- Petrochemical refineries: Cooling compressors, heat exchangers, and other refinery equipment.

- Manufacturing: Maintaining optimal temperatures for machinery, electronics, and production lines.

- Data centers: Dissipating the heat generated by servers, networking equipment, and other IT infrastructure.

The versatility of air-cooled heat exchangers has made them a preferred choice for industries seeking reliable, efficient, and low-maintenance thermal management solutions.

The Advantages of Air-Cooled Heat Exchangers

Compared to their liquid-cooled counterparts, air-cooled heat exchangers offer several distinct advantages that have driven their widespread adoption:

-

Simplicity and Reliability: The absence of complex liquid cooling systems, such as pumps, valves, and piping, makes air-cooled heat exchangers inherently simpler in design and operation. This simplicity translates to increased reliability, as there are fewer moving parts and potential failure points.

-

Reduced Maintenance Requirements: With no liquid coolant to monitor, refill, or dispose of, air-cooled heat exchangers require minimal maintenance. Regular cleaning and inspections are typically the only maintenance tasks necessary, reducing the overall operational costs.

-

Adaptability and Flexibility: ACHEs can be designed and configured to accommodate a wide range of equipment sizes, heat loads, and environmental conditions, making them highly adaptable to diverse industrial settings.

-

Reduced Environmental Impact: By eliminating the need for water or specialized coolants, air-cooled heat exchangers significantly reduce the environmental footprint associated with industrial cooling systems, contributing to more sustainable operations.

-

Lower Capital and Operating Costs: The simpler design and reduced maintenance requirements of air-cooled heat exchangers often result in lower initial investment and ongoing operating costs compared to liquid-based cooling solutions.

These advantages have positioned air-cooled heat exchangers as a preferred choice for industries seeking efficient, reliable, and cost-effective thermal management solutions.

Advancing Air-Cooled Heat Exchanger Design and Performance

As industrial demands for higher efficiency and sustainability continue to grow, the evolution of air-cooled heat exchanger design and performance has become a central focus for engineers and researchers. Innovations in materials, geometry, and airflow optimization have led to significant advancements in ACHE technology, further enhancing their capabilities in industrial applications.

Material Innovations

The selection of materials plays a crucial role in the performance and longevity of air-cooled heat exchangers. Traditionally, materials such as aluminum and copper have been widely used due to their high thermal conductivity. However, the emergence of advanced materials, including lightweight composites and specialized alloys, has expanded the design possibilities for ACHEs.

These innovative materials offer enhanced thermal properties, improved corrosion resistance, and reduced weight, enabling the creation of more compact and efficient heat exchanger designs. For instance, the use of aluminum-magnesium alloys has resulted in heat exchangers with improved strength-to-weight ratios, making them suitable for applications where weight is a critical factor, such as in the aerospace industry.

Geometric Optimizations

The geometry of air-cooled heat exchangers directly impacts their heat transfer efficiency and airflow characteristics. Researchers and engineers have explored various design configurations, including fin spacing, fin shape, and tube arrangements, to optimize heat transfer and minimize pressure drops.

The integration of advanced computational fluid dynamics (CFD) simulations has been instrumental in refining ACHE geometries. These virtual modeling tools allow for the exploration of different design iterations, enabling the identification of optimal configurations that maximize heat dissipation while minimizing energy consumption.

For example, the use of wavy or serrated fins has been shown to enhance the turbulence of airflow, leading to improved heat transfer rates compared to traditional straight fins. Similarly, the strategic placement and orientation of tubes within the heat exchanger can be optimized to create more uniform airflow patterns, further boosting thermal performance.

Airflow Optimization

Efficient airflow management is a critical aspect of air-cooled heat exchanger design. Innovations in fan and blower technologies, as well as the incorporation of advanced air distribution systems, have revolutionized the way ACHEs handle and dissipate heat.

The deployment of variable-speed fans and smart control systems allows for dynamic airflow regulation, adjusting the cooling capacity based on real-time temperature demands. This adaptive approach ensures that the heat exchanger operates at optimal efficiency, conserving energy and reducing operational costs.

Additionally, the integration of innovative air duct designs and baffling systems has enabled more uniform air distribution across the heat exchanger surfaces, minimizing hot spots and enhancing overall cooling performance.

Addressing Operational Challenges and Maintenance Considerations

While air-cooled heat exchangers offer numerous benefits, they also present unique operational challenges that require thoughtful maintenance strategies to ensure long-term reliability and efficiency.

Mitigating Fouling and Corrosion

One of the primary concerns with air-cooled heat exchangers is the potential for fouling, where airborne contaminants, dust, or biological growth accumulate on the heat transfer surfaces. This buildup can significantly impair heat transfer efficiency, leading to reduced cooling capacity and increased energy consumption.

To address this challenge, regular inspections, cleaning procedures, and the incorporation of anti-fouling coatings or surface treatments have become essential maintenance practices. Implementing a proactive approach to fouling management helps maintain optimal heat exchanger performance and minimize the risk of costly downtime.

Corrosion poses another threat to the longevity of air-cooled heat exchangers, particularly in harsh industrial environments. The selection of corrosion-resistant materials, such as stainless steel or specialized alloys, and the application of protective coatings can help mitigate the impact of corrosion, ensuring the heat exchanger’s structural integrity and extended service life.

Optimizing Airflow and Maintaining Cleanliness

Maintaining optimal airflow is crucial for the efficient operation of air-cooled heat exchangers. Regularly cleaning the heat exchanger surfaces, removing any accumulated debris or obstructions, and ensuring the proper functioning of fans or blowers can significantly improve heat dissipation and maintain thermal performance.

Implementing preventive maintenance schedules, including routine inspections and cleaning, helps maintain the heat exchanger’s cleanliness and airflow efficiency, ultimately contributing to its overall reliability and longevity.

Monitoring and Optimization

Continuous monitoring and data-driven optimization have become essential tools in maintaining the efficiency and performance of air-cooled heat exchangers. The integration of advanced sensors and control systems allows for real-time tracking of critical parameters, such as temperatures, pressure drops, and airflow rates.

By leveraging this data, operators can identify potential issues, optimize operating conditions, and proactively implement maintenance actions to ensure the heat exchanger’s optimal performance. Additionally, the analysis of historical data can help predict maintenance needs and enable predictive maintenance strategies, minimizing unplanned downtime and associated costs.

Emerging Trends and Future Developments

As the demand for efficient and sustainable industrial cooling solutions continues to grow, the landscape of air-cooled heat exchanger technology is undergoing rapid advancements. Several emerging trends and future developments are shaping the future of this critical thermal management component.

Hybrid Cooling Approaches

The integration of air-cooled heat exchangers with other cooling technologies, such as evaporative cooling or liquid-assisted systems, has given rise to hybrid cooling approaches. These hybrid solutions combine the advantages of different cooling methods, offering enhanced flexibility and optimization opportunities.

For instance, the integration of air-cooled heat exchangers with evaporative cooling systems can provide improved heat dissipation in arid or hot climates, where the latent heat of evaporation can significantly enhance cooling efficiency. Similarly, the combination of air-cooled heat exchangers with liquid-based cooling loops can offer the best of both worlds, leveraging the simplicity and reliability of air cooling while benefiting from the higher heat transfer rates of liquid cooling.

Additive Manufacturing and Customization

The advent of additive manufacturing, commonly known as 3D printing, has opened up new possibilities for the design and fabrication of air-cooled heat exchangers. This technology enables the creation of highly customized heat exchanger geometries, allowing for the optimization of airflow, heat transfer, and weight characteristics to meet specific industry requirements.

Additive manufacturing also facilitates the rapid prototyping and testing of innovative heat exchanger designs, accelerating the development and implementation of advanced ACHE solutions. This level of customization and agility aligns with the growing demand for tailored thermal management systems across diverse industrial applications.

Intelligent Monitoring and Predictive Maintenance

The integration of advanced sensor technologies, data analytics, and machine learning algorithms is transforming the way air-cooled heat exchangers are monitored and maintained. Intelligent monitoring systems can continuously track key performance indicators, such as temperature, pressure, vibration, and airflow, providing real-time insights into the heat exchanger’s operational status.

By leveraging predictive analytics, these intelligent systems can identify potential issues before they manifest, enabling proactive maintenance strategies. This shift towards predictive maintenance helps minimize unplanned downtime, optimize equipment lifespan, and reduce overall maintenance costs, ultimately enhancing the overall efficiency and reliability of air-cooled heat exchanger systems.

Sustainability and Environmental Considerations

As the global focus on sustainability and environmental responsibility intensifies, the development of air-cooled heat exchangers is also being shaped by the need for more eco-friendly and energy-efficient solutions. Manufacturers are increasingly exploring the use of recyclable or biodegradable materials, as well as the integration of renewable energy sources, such as solar power, to power the cooling systems.

Furthermore, the pursuit of improved energy efficiency in air-cooled heat exchangers includes advancements in fan and blower technologies, the optimization of airflow patterns, and the integration of advanced controls to match cooling capacity with real-time demands. These initiatives aim to reduce the overall energy consumption and carbon footprint associated with industrial cooling systems, aligning with the broader sustainability goals of modern industrial operations.

Conclusion: Embracing the Future of Air-Cooled Heat Exchangers

The role of air-cooled heat exchangers in industrial processes has evolved significantly, transforming from reliable workhorses to innovative and versatile thermal management solutions. As industries strive for greater efficiency, sustainability, and reliability, the advancements in ACHE design, materials, and operational strategies have become increasingly crucial.

By leveraging the fundamental principles of heat transfer, optimizing airflow and geometric configurations, and integrating intelligent monitoring systems, air-cooled heat exchangers have emerged as essential components in the quest for industrial excellence. As the landscape continues to evolve, embracing these cutting-edge technologies and maintenance strategies will be instrumental in ensuring the longevity, efficiency, and environmental responsibility of industrial operations.

Across sectors, from power generation and petrochemicals to manufacturing and data centers, air-cooled heat exchangers have proven their mettle as reliable and cost-effective thermal management solutions. By understanding the latest developments and best practices, industrial stakeholders can harness the full potential of these versatile heat exchangers, unlocking new levels of performance, sustainability, and competitive advantage.

Visit our website to explore the latest advancements in air-cooled heat exchanger technology and learn how these innovative solutions can transform your industrial operations.