Optimizing Thermal Management for the Digital Age

In the fast-paced world of modern infrastructure, where data centers, industrial facilities, and mission-critical systems demand ever-increasing power and performance, efficient cooling has become a pivotal challenge. As the relentless march of technological progress pushes the boundaries of what’s possible, the need for innovative heat exchanger designs has never been more pressing.

Addressing the Cooling Conundrum in Data Centers

The rise of artificial intelligence (AI) and data-intensive applications has transformed the landscape of data centers, driving a surge in power consumption and heat generation. Data centers now account for approximately 2% of total U.S. electricity consumption, with cooling alone responsible for up to 40% of a data center’s energy usage. This energy-intensive reality, coupled with growing environmental concerns, has prompted a call for game-changing cooling solutions.

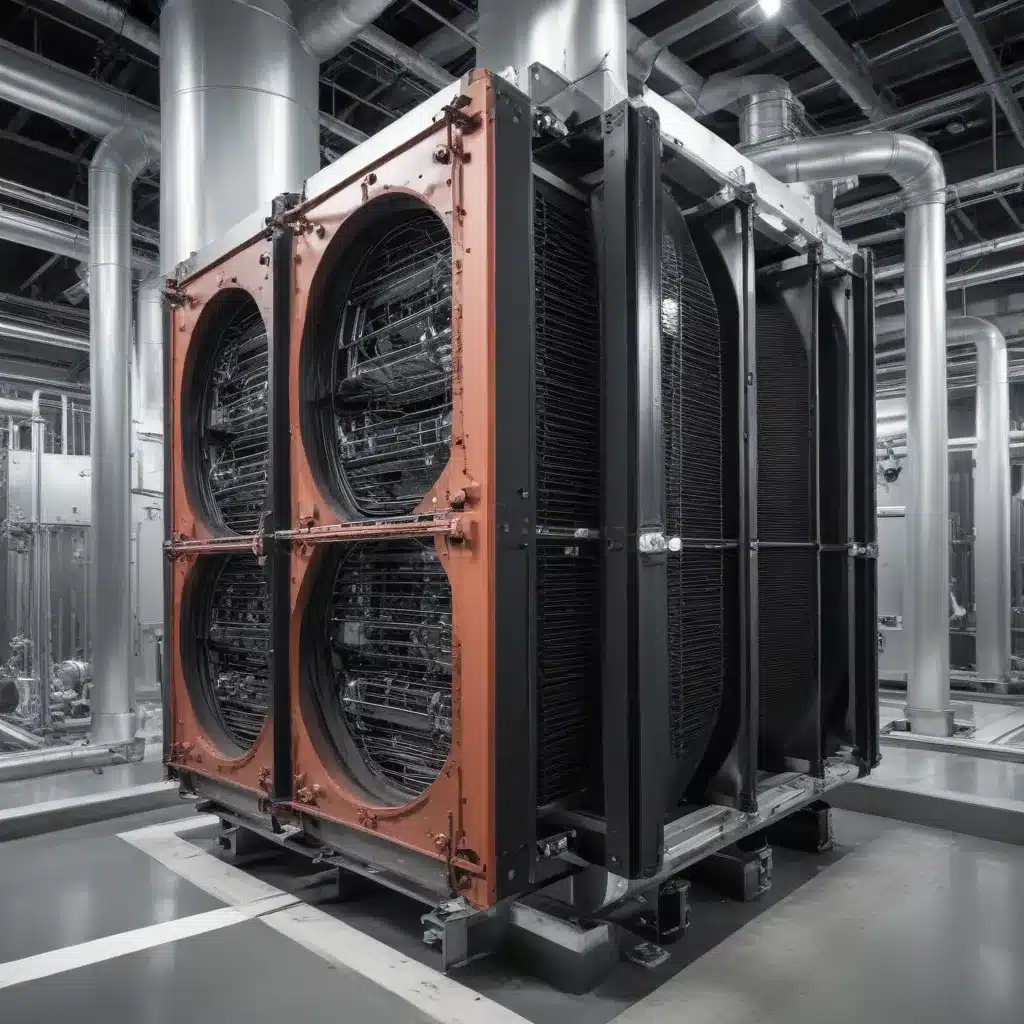

One such innovation that has proven highly effective in addressing the cooling challenges of the AI era is the rear door heat exchanger (RDHx). These air-assisted liquid cooling systems are strategically positioned at the rear of server racks, removing heat directly at the source and dramatically reducing the hot air that enters the data center’s ambient environment. By leveraging the efficiency of air-assisted liquid cooling, rear door heat exchangers can significantly lower energy consumption compared to traditional cooling methods like computer room air conditioning (CRAC) units.

“Rear door heat exchanger units use air-assisted liquid cooling technology, which is far more efficient at transferring heat compared to air,” explains Klaus Dafinger, cooling marketing manager at Legrand. “This efficiency reduces the energy required for cooling and aligns with sustainability goals by minimizing the overall carbon footprint of data centers.”

Scaling Cooling Capacity for High-Density Environments

As AI workloads continue to grow, data centers must adapt to rapidly changing demands. Rear door heat exchanger systems offer a scalable cooling solution that can be easily integrated into existing infrastructure, whether dealing with incremental upgrades or major expansions. This flexibility is crucial for data centers that need to quickly respond to the evolving requirements of AI-driven applications.

Moreover, rear door heat exchanger systems are designed to ensure continuous operation even under the heavy thermal loads typical of AI workloads. The air-assisted liquid cooling mechanism is highly effective at maintaining consistent temperatures, preventing overheating, and reducing the risk of hardware failures – a critical factor for supporting mission-critical AI applications where downtime is not an option.

Optimizing Space and Cost-Effectiveness

Space is a valuable commodity in data centers, and rear door heat exchanger systems help optimize it by eliminating the need for large, dedicated cooling units within the facility. This compact design frees up valuable floor space for additional server racks or other critical infrastructure, a significant advantage for data centers looking to maximize their available real estate.

Beyond space optimization, rear door heat exchanger systems offer a cost-effective solution for data centers. The reduced energy consumption directly translates into lower operational costs, and the ability to maintain optimal temperatures extends the lifespan of data center equipment, reducing the need for frequent replacements and associated expenses. These factors combine to make rear door heat exchanger systems a compelling choice for modern data centers.

Embracing Sustainable Cooling Practices

As the world becomes increasingly conscious of environmental impact, data centers are under pressure to minimize their carbon footprint and adopt more sustainable practices. Rear door heat exchanger technology aligns perfectly with this imperative, offering a path towards enhanced cooling efficiency and reduced energy consumption.

“Rear door heat exchanger units from Legrand’s USystems brand, such as the ColdLogik RDHx, allow load removal of up to 200 kW per cabinet, providing unprecedented levels of sustainable cooling efficiency and significant operational savings by reducing overall energy consumption and CO2 emissions,” Dafinger explains. “Its closed water loop system significantly reduces water usage, bringing water usage effectiveness (WUE) down to zero, further enhancing its environmental credentials.”

Preparing for the Future of Data Center Cooling

As AI technology continues to advance, the demands on data center infrastructure will only increase. Rear door heat exchanger systems provide a future-proof cooling solution capable of handling these growing demands, ensuring data centers are equipped to support the next generation of AI advancements without compromising on performance or efficiency.

By investing in rear door heat exchanger technology, data centers can future-proof their cooling infrastructure and position themselves for long-term success in the digital age. From enhanced cooling efficiency and reduced energy consumption to scalability, space optimization, reliability, and cost-effectiveness, rear door heat exchangers are poised to play a crucial role in the evolution of data center cooling.

Innovating Beyond Data Centers: Applications Across Industries

While the data center industry has been at the forefront of driving advancements in heat exchanger design, the benefits of these innovative cooling solutions extend far beyond the digital realm. Across a wide range of industries, from manufacturing to healthcare, the need for efficient and reliable thermal management is paramount.

Optimizing Industrial Processes

In the manufacturing sector, heat exchangers play a vital role in facilitating various industrial processes, from chemical production to metal fabrication. As production demands continue to rise, the ability to maintain precise temperature control and minimize energy consumption has become increasingly critical.

Innovative heat exchanger designs, such as those featuring enhanced heat transfer surfaces, intelligent monitoring systems, and modular configurations, can significantly improve the efficiency and reliability of industrial operations. By optimizing heat exchanger performance, manufacturers can reduce operational costs, minimize downtime, and enhance product quality – all while contributing to more sustainable manufacturing practices.

Ensuring Safety and Reliability in Critical Infrastructure

Beyond industrial applications, heat exchangers are also crucial in safeguarding critical infrastructure, such as power generation facilities, transportation hubs, and healthcare centers. In these mission-critical environments, where system failures can have severe consequences, the need for robust and reliable cooling solutions is paramount.

Advancements in heat exchanger technology, including the integration of advanced materials, predictive maintenance algorithms, and redundancy features, have enabled these systems to withstand the rigors of demanding applications and ensure uninterrupted operations. By enhancing the thermal management capabilities of critical infrastructure, heat exchanger innovations help protect vital services and safeguard the well-being of communities.

Addressing Sustainability Challenges Across Sectors

As the global community grapples with the pressing issue of climate change, the demand for sustainable cooling solutions has become increasingly urgent. Heat exchanger manufacturers and designers have responded by developing innovative technologies that not only improve efficiency but also minimize the environmental impact of cooling systems.

From the integration of renewable energy sources to the adoption of eco-friendly refrigerants and water-saving features, the latest heat exchanger designs are optimized to reduce carbon footprints and resource consumption. By empowering industries and infrastructure to adopt more sustainable cooling practices, these advancements in heat exchanger technology are contributing to a greener, more resilient future.

Fostering Collaboration and Knowledge Sharing

The continued evolution of heat exchanger design and applications is not the work of a single entity, but rather the culmination of a collaborative effort involving researchers, engineers, industry experts, and end-users. By fostering knowledge sharing and cross-pollination of ideas, the air-cooled heat exchanger community is driving innovation forward, addressing complex challenges, and pushing the boundaries of what’s possible.

Platforms like the Air Cooled Heat Exchangers blog serve as hubs for industry professionals to engage in meaningful dialogue, share practical insights, and explore the latest advancements in thermal management technology. This collaborative spirit is essential in driving the development of innovative cooling solutions that can meet the diverse needs of modern industries and critical infrastructure.

Conclusion: Embracing the Future of Cooling

As the world becomes increasingly reliant on data-driven technologies, energy-intensive infrastructure, and mission-critical systems, the demand for efficient and reliable cooling solutions has never been more pressing. The advancements in heat exchanger design, exemplified by the rise of rear door heat exchangers in data centers, have set the stage for a new era of thermal management innovation.

By embracing these cutting-edge cooling technologies, industries and critical infrastructure across the globe can unlock a future of enhanced performance, reduced environmental impact, and greater operational resilience. As we navigate the challenges of the digital age and the imperative of sustainability, the innovative cooling solutions explored in this article offer a pathway towards a more efficient, reliable, and future-proof landscape of infrastructure and industrial processes.