The Critical Role of Air-Cooled Heat Exchangers Across Industries

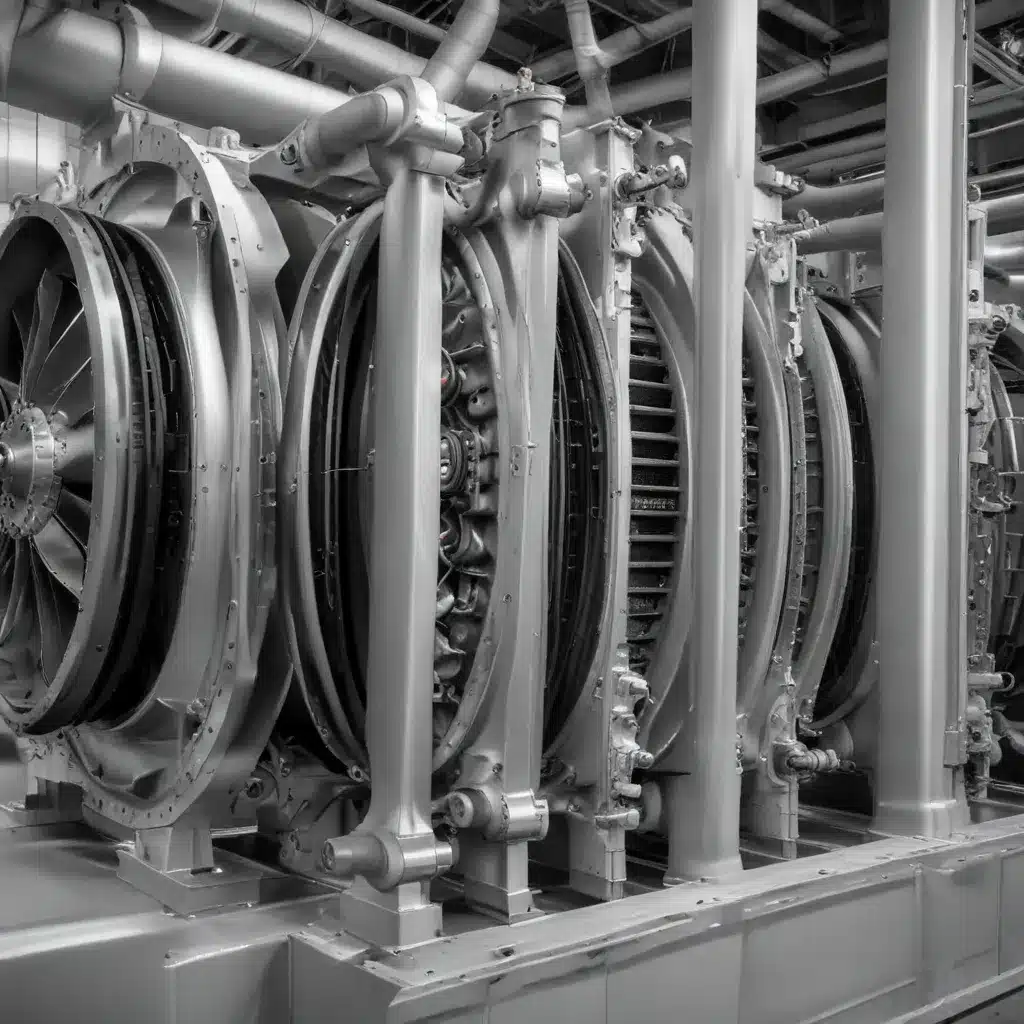

Air-cooled heat exchangers are ubiquitous in a wide range of industrial applications, from power generation and petrochemical processing to HVAC systems and automotive manufacturing. These workhorses of thermal management play a vital role in maintaining efficient operations, minimizing energy consumption, and ensuring equipment longevity. However, as air-cooled heat exchangers age and operating conditions fluctuate, their performance can degrade, leading to increased maintenance costs, unplanned downtime, and even catastrophic failures if not properly monitored and maintained.

To address these challenges, leading companies are turning to advanced fault diagnostics and prognostics – sophisticated techniques that can detect early-stage degradation, predict remaining useful life, and enable proactive maintenance strategies. By leveraging the power of sensor data, physics-based models, and machine learning, air-cooled heat exchanger operators can gain unprecedented visibility into the health of their critical assets, empowering them to optimize performance, minimize risk, and unlock new levels of reliability and cost savings.

Mastering the Complexities of Air-Cooled Heat Exchanger Failure Modes

Air-cooled heat exchangers face a unique set of operating conditions and failure mechanisms that can compromise their performance over time. Understanding these failure modes is the key to developing effective diagnostics and prognostics strategies.

One of the primary failure modes in air-cooled heat exchangers is fouling, where airborne contaminants, dust, and debris accumulate on the heat transfer surfaces, reducing heat transfer efficiency and increasing pressure drop. This gradual degradation can lead to a loss of cooling capacity, higher energy consumption, and eventual system failure if not addressed.

Another common failure mode is corrosion, which can attack the metal components of the heat exchanger, including the tubes, fins, and headers. Corrosion can be accelerated by factors such as harsh environmental conditions, poor water treatment, or the introduction of incompatible materials. As corrosion progresses, it can cause structural weakening, leaks, and even catastrophic failures.

Vibration-induced damage is also a significant concern for air-cooled heat exchangers, particularly those operating in industrial settings with high levels of ambient vibration. This can lead to fatigue cracking, tube loosening, and other mechanical failures that compromise the integrity of the system.

To mitigate these failure modes, air-cooled heat exchanger operators must employ a combination of preventive maintenance, regular inspections, and advanced diagnostic techniques. This holistic approach helps identify issues early, predict future problems, and enable timely interventions to maintain reliable operation.

Harnessing the Power of Sensor Data for Predictive Maintenance

One of the key enablers of advanced fault diagnostics and prognostics for air-cooled heat exchangers is the increasing availability and affordability of sensor technologies. By strategically placing sensors throughout the heat exchanger system, operators can gather a wealth of real-time data on critical parameters such as:

- Inlet and outlet temperatures: Monitoring temperature changes can provide early indications of fouling or other performance degradation.

- Pressure drop: Measuring the pressure drop across the heat exchanger can reveal the onset of fouling or other blockages.

- Vibration levels: Tracking vibration patterns can help detect mechanical issues, such as loose components or impending failures.

- Corrosion indicators: Sensors that monitor pH, conductivity, or other corrosion-related factors can provide valuable insights into the state of the heat exchanger’s materials.

By continuously collecting and analyzing this sensor data, air-cooled heat exchanger operators can gain a comprehensive understanding of their asset’s health and performance. Advanced analytics, including machine learning algorithms and physics-based models, can then be leveraged to identify anomalies, predict remaining useful life, and recommend optimal maintenance strategies.

Leveraging Physics-of-Failure Models for Prognostics

While sensor data provides critical real-time insights, a deeper understanding of the underlying physics governing air-cooled heat exchanger behavior is essential for developing accurate prognostic models. This “physics-of-failure” approach involves:

-

Identifying Failure Modes: Thoroughly analyzing the various failure mechanisms, such as fouling, corrosion, and vibration-induced damage, to understand how they manifest and progress over time.

-

Modeling Degradation Processes: Developing mathematical models that capture the kinetics of these failure mechanisms, enabling the prediction of how performance parameters will change as the heat exchanger ages.

-

Integrating Sensor Data: Combining the physics-based models with the sensor data to create a comprehensive, data-driven prognostic framework that can accurately forecast remaining useful life.

By adopting this physics-of-failure methodology, air-cooled heat exchanger operators can move beyond reactive maintenance strategies and instead proactively manage their assets. Prognostic models can warn of impending failures, empowering maintenance teams to schedule interventions at the optimal time, minimizing downtime and maximizing equipment lifespan.

Optimizing Air-Cooled Heat Exchanger Performance Through Condition-Based Maintenance

Armed with the insights gained from advanced fault diagnostics and prognostics, air-cooled heat exchanger operators can transition from time-based, reactive maintenance to a more intelligent, condition-based approach. This shift yields numerous benefits, including:

-

Reduced Maintenance Costs: By targeting maintenance activities based on the actual condition of the heat exchanger, operators can avoid unnecessary or premature interventions, leading to significant cost savings.

-

Improved Reliability and Uptime: Proactive maintenance strategies enabled by prognostics can help prevent unexpected failures, ensuring the heat exchanger operates at peak efficiency for longer periods.

-

Extended Equipment Lifespan: By monitoring and addressing degradation issues before they become critical, operators can extend the useful life of their air-cooled heat exchangers, maximizing their return on investment.

-

Increased Energy Efficiency: Maintaining optimal heat transfer performance through proactive maintenance can help reduce the energy consumption of the overall system, lowering operating costs and environmental impact.

To effectively implement condition-based maintenance, air-cooled heat exchanger operators must establish a comprehensive monitoring and decision-support framework. This may involve integrating the prognostic models with computerized maintenance management systems (CMMS), enterprise asset management (EAM) platforms, or other industrial IoT technologies to enable seamless data exchange and streamlined maintenance planning.

Navigating the Challenges of Implementing Advanced Diagnostics and Prognostics

While the benefits of advanced fault diagnostics and prognostics for air-cooled heat exchangers are clear, the implementation of these technologies can present several challenges that must be addressed:

-

Data Integration and Interoperability: Ensuring smooth data flow between sensors, prognostic models, and maintenance management systems requires careful planning and integration of various software and hardware components.

-

Model Validation and Accuracy: Developing reliable prognostic models requires extensive testing, validation, and refinement to ensure they accurately reflect the real-world behavior of air-cooled heat exchangers.

-

Organizational Change Management: Transitioning from traditional maintenance practices to a condition-based approach often requires cultural and procedural changes within an organization, which can be challenging to implement.

-

Talent and Skill Development: Effectively leveraging advanced diagnostics and prognostics technologies requires specialized skills in areas such as data analysis, machine learning, and predictive maintenance. Investing in employee training and development is crucial.

To overcome these challenges, air-cooled heat exchanger operators should adopt a phased, collaborative approach, working closely with experienced specialists, technology providers, and industry peers to develop and refine their predictive maintenance strategies. By embracing the power of advanced fault diagnostics and prognostics, they can unlock new levels of reliability, efficiency, and cost savings for their critical air-cooled heat exchanger assets.

Conclusion: The Future of Air-Cooled Heat Exchanger Reliability

As industries continue to demand higher levels of uptime, energy efficiency, and cost-effectiveness, the role of air-cooled heat exchangers will only become more crucial. By harnessing the latest advancements in fault diagnostics and prognostics, air-cooled heat exchanger operators can transform their maintenance practices, ensuring their critical assets perform reliably and optimally for years to come.

The future of air-cooled heat exchanger reliability lies in the seamless integration of sensor data, physics-based models, and predictive analytics. By embracing these innovative technologies, forward-thinking organizations can gain unparalleled visibility into the health and performance of their heat exchangers, empowering them to make data-driven decisions, reduce maintenance costs, and maximize the lifespan of their critical thermal management systems.

To learn more about how your organization can enhance the reliability of its air-cooled heat exchangers through advanced fault diagnostics and prognostics, visit https://www.aircooledheatexchangers.net/.