The Role of Predictive Maintenance in Enhancing Air-Cooled Heat Exchanger Performance

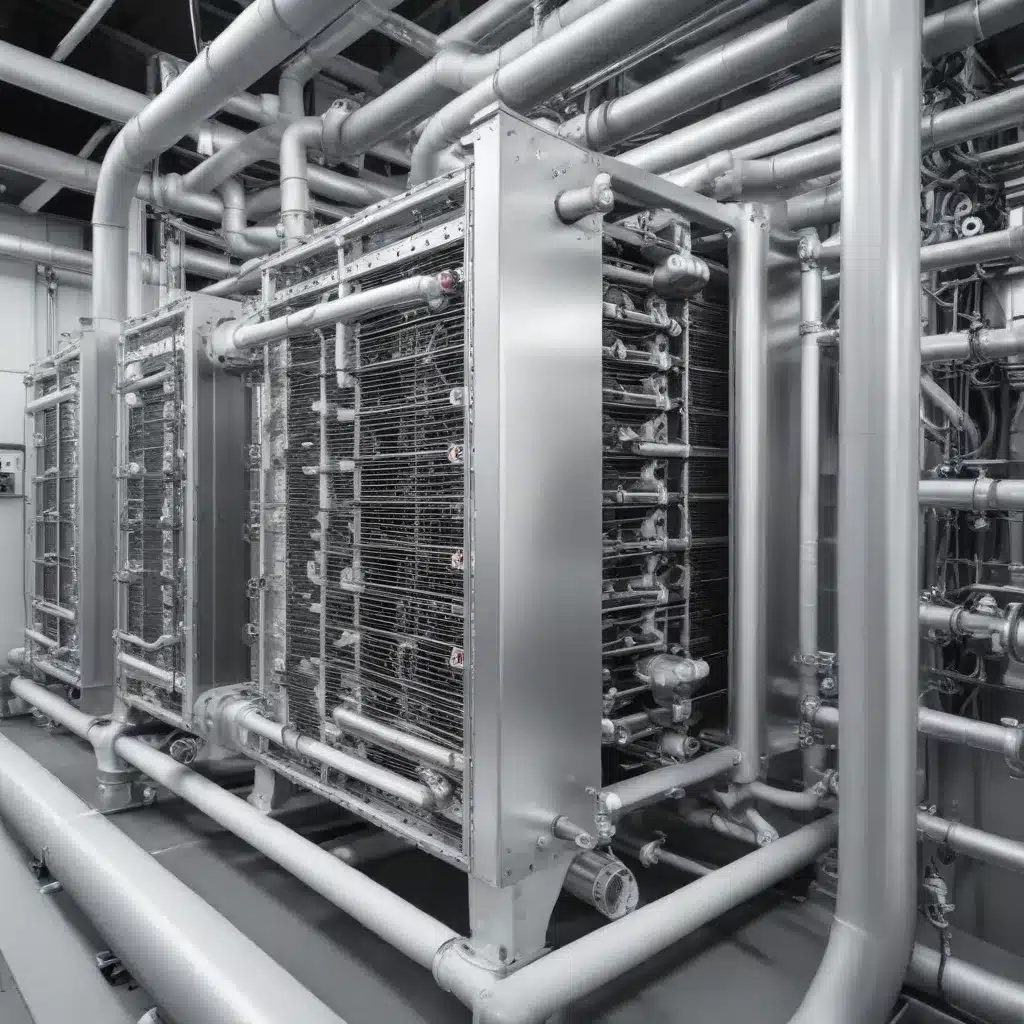

Air-cooled heat exchangers are a critical component in many pharmaceutical manufacturing facilities, responsible for regulating temperatures and humidity levels to ensure product quality and worker comfort. However, maintaining these heat exchangers can be a complex and time-consuming task, requiring regular inspections, cleaning, and repairs to prevent issues like fouling, corrosion, and mechanical failures.

Fortunately, the integration of predictive analytics and condition-based optimization techniques can significantly improve the maintenance and performance of air-cooled heat exchangers in pharmaceutical environments. By leveraging advanced data analysis and machine learning algorithms, facility managers can proactively identify potential problems, optimize operating parameters, and extend the overall lifespan of these mission-critical systems.

Implementing Predictive Maintenance Strategies

One of the key advantages of predictive maintenance is the ability to identify equipment issues before they lead to critical failures or unplanned downtime. This is particularly important for air-cooled heat exchangers, which can be prone to gradual performance degradation over time due to factors like:

- Fouling of heat transfer surfaces from airborne contaminants

- Corrosion of metal components from exposure to corrosive chemicals or environmental conditions

- Mechanical wear and tear on fans, bearings, and other moving parts

By continuously monitoring operational data such as temperatures, pressures, vibration levels, and energy consumption, predictive maintenance algorithms can detect anomalies and trends that indicate developing problems. This allows facility managers to schedule targeted maintenance activities, such as cleaning, part replacements, or system adjustments, before a catastrophic failure occurs.

Optimizing Air-Cooled Heat Exchanger Operations

In addition to predictive maintenance, condition-based optimization techniques can help pharmaceutical facilities maximize the efficiency and reliability of their air-cooled heat exchangers. These methods involve using real-time data and advanced analytics to fine-tune operating parameters, such as:

- Fan speed and airflow: Adjusting fan speeds to match the facility’s cooling demands can save energy and prevent over-cooling.

- Cleaning frequency: Monitoring the rate of fouling can help determine the optimal cleaning schedule to maintain heat transfer performance.

- Refrigerant charge: Monitoring refrigerant levels and adjusting as needed can improve cooling capacity and energy efficiency.

By continuously optimizing these parameters based on the heat exchanger’s condition and the facility’s changing needs, pharmaceutical companies can maximize the performance, energy efficiency, and lifespan of their air-cooled heat exchangers.

Overcoming Challenges in Data Integration and Analysis

Implementing predictive maintenance and condition-based optimization strategies for air-cooled heat exchangers in pharmaceutical facilities requires the integration of data from various sources, including:

- Building management systems (BMS) that monitor temperature, humidity, and other environmental parameters

- Maintenance records and work orders

- Equipment sensors that track operational data like vibration, pressure, and energy consumption

Consolidating and analyzing this data can be a significant challenge, as it often resides in disparate systems and databases. However, the use of advanced analytics platforms, such as AI-powered predictive maintenance solutions from Siemens, can help pharmaceutical facilities overcome these challenges.

These platforms leverage machine learning algorithms to identify patterns and anomalies in the data, automating the process of fault detection and diagnostics. By integrating data from multiple sources and applying predictive models, facility managers can gain a comprehensive understanding of their air-cooled heat exchanger’s performance and proactively address any issues.

Achieving Optimization through Collaborative Approaches

Implementing successful predictive maintenance and condition-based optimization strategies for air-cooled heat exchangers in pharmaceutical facilities often requires a collaborative approach involving several key stakeholders, including:

- Facility management and operations teams, who have in-depth knowledge of the facility’s HVAC systems and maintenance practices

- Process engineers and subject matter experts, who can provide insights into the specific temperature and humidity requirements for pharmaceutical manufacturing processes

- Data analysts and IT professionals, who can design and maintain the data integration and analytics infrastructure

- Equipment manufacturers and service providers, who can offer expertise on the proper maintenance and optimization of air-cooled heat exchangers

By fostering cross-functional collaboration and leveraging the expertise of these various stakeholders, pharmaceutical facilities can develop a tailored, data-driven approach to air-cooled heat exchanger maintenance and optimization that meets their unique needs and requirements.

Conclusion: Enhancing Reliability and Sustainability through Predictive Analytics

Predictive maintenance and condition-based optimization strategies have the potential to transform the way pharmaceutical facilities manage their air-cooled heat exchangers. By leveraging advanced data analysis and machine learning, facility managers can proactively identify and address potential issues, optimize operating parameters, and extend the lifespan of these critical systems.

The integration of these technologies not only enhances the reliability and performance of air-cooled heat exchangers, but also contributes to improved energy efficiency and sustainability – crucial considerations for pharmaceutical manufacturers seeking to reduce their environmental impact and operating costs. As the industry continues to evolve, the adoption of these innovative maintenance and optimization techniques will be a key factor in ensuring the long-term success and competitiveness of pharmaceutical facilities.

To learn more about how Air Cooled Heat Exchangers can help your pharmaceutical facility optimize its air-cooled heat exchanger performance, visit our website or contact us today.

Key Takeaways

- Predictive maintenance and condition-based optimization strategies can significantly improve the reliability and performance of air-cooled heat exchangers in pharmaceutical facilities.

- By continuously monitoring operational data and applying advanced analytics, facility managers can identify potential issues before they lead to critical failures or unplanned downtime.

- Optimizing parameters like fan speed, cleaning frequency, and refrigerant charge can enhance the energy efficiency and lifespan of air-cooled heat exchangers.

- Overcoming data integration and analysis challenges requires a collaborative approach involving various stakeholders, including facility management, process engineers, and IT professionals.

- Adopting these innovative maintenance and optimization techniques can contribute to improved reliability, energy efficiency, and sustainability for pharmaceutical manufacturers.