The Role of Computational Fluid Dynamics in Heat Exchanger Design

Heat exchangers are critical components in a wide range of industries, from chemical processing and power generation to HVAC systems. As energy efficiency becomes increasingly important, advanced computational techniques have revolutionized the design and optimization of these critical pieces of equipment. Computational Fluid Dynamics (CFD) has emerged as a powerful tool for heat exchanger engineers, allowing them to create detailed models of fluid flow and heat transfer within complex geometries.

The benefits of leveraging CFD in heat exchanger design are numerous. By simulating the intricate fluid dynamics and thermal behavior within the exchanger, engineers can:

- Reduce development time and costs: CFD models enable rapid iteration and testing of multiple design options, shortening the overall design cycle.

- Improve understanding of flow patterns and thermal behavior: Detailed visualization of temperature and pressure distributions provides valuable insights into the exchanger’s performance.

- Optimize design for efficiency: CFD analyses help maximize heat transfer rates while minimizing pressure drops and material costs.

Structural Analysis with Finite Element Methods

In addition to CFD, Finite Element Analysis (FEA) has become an essential tool in the design of shell-and-tube heat exchangers. FEA allows engineers to assess the structural integrity and thermal performance of exchanger components, such as tubes, tubesheets, and shells, under realistic operating conditions.

By simulating the effects of pressure, temperature, and thermal expansion, FEA helps identify potential failure points and ensures that the heat exchanger can withstand various loads without compromising performance. This analysis is crucial for meeting safety standards and optimizing material usage, leading to more efficient and cost-effective designs.

FEA provides a detailed understanding of how the heat exchanger will behave under real-world conditions, enabling engineers to make informed decisions and design safer, more reliable equipment.

Leveraging Specialized Software for Thermal and Hydraulic Analysis

While CFD and FEA offer powerful simulation capabilities, the complexity of heat exchanger design has also led to the development of specialized software tools tailored for these applications. One such platform is HTRI Xist, which is widely used across various industries for the thermal and hydraulic analysis of shell-and-tube heat exchangers.

HTRI Xist leverages advanced algorithms and a vast, proprietary database of experimental and field data to predict key performance metrics, such as heat transfer rates, pressure drops, and overall efficiency. This extensive knowledge base, gathered from decades of research and real-world testing, ensures that the software’s correlations are both accurate and reliable.

By providing users with the ability to optimize designs for efficiency, safety, and compliance with industry standards, HTRI Xist plays a crucial role in the engineering of heat exchangers. The software’s capabilities are particularly valuable in industries where precise heat exchanger performance is critical, such as chemical processing, power generation, and HVAC systems.

Optimizing Air-Cooled Heat Exchangers

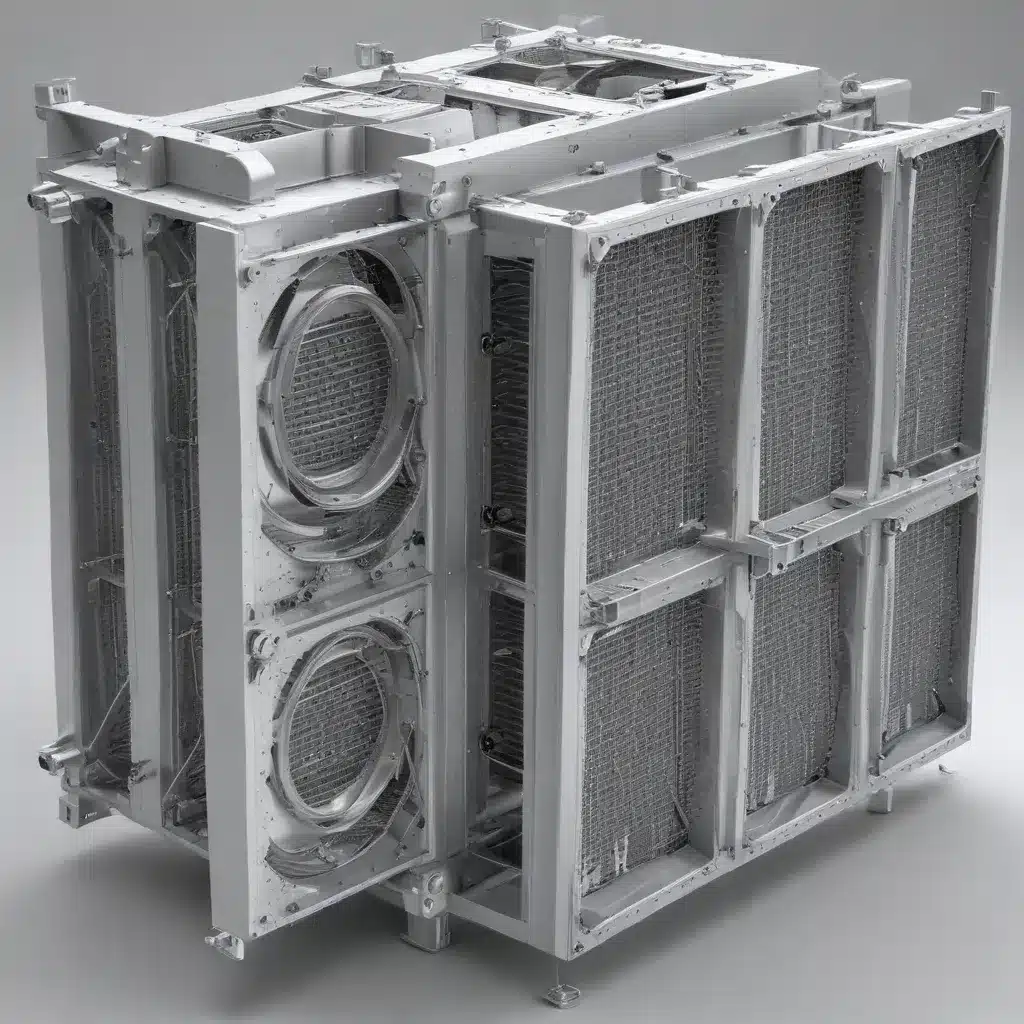

The principles of CFD, FEA, and specialized software tools apply not only to shell-and-tube heat exchangers but also to air-cooled heat exchangers, which are widely used in a variety of industrial applications. The HTRI XACE software, for example, is designed specifically for the thermal and hydraulic analysis of air-cooled heat exchangers.

XACE enables engineers to design, rate, and optimize these exchangers by simulating performance under various operating conditions. The software considers factors like airflow distribution, fan performance, and finned tube arrangements, allowing users to evaluate and enhance the exchanger’s effectiveness.

By providing accurate predictions of heat transfer rates, pressure drops, and overall efficiency, XACE helps ensure that air-cooled heat exchangers meet desired specifications and operate efficiently in real-world applications.

Optimizing Fan Performance for Air-Cooled Exchangers

A critical component of air-cooled heat exchangers is the fan, which plays a crucial role in the exchanger’s overall cooling performance. Proper fan selection and evaluation are essential to ensure adequate airflow, pressure rise, and energy efficiency.

Computational tools are used to analyze fan performance by incorporating factors such as airflow rate, fan speed, pressure drop, and power consumption. Engineers input the operating conditions, including ambient temperature and air density, and the software calculates the expected airflow, pressure rise, and power requirement. This analysis allows for the optimization of fan selection and operation, ensuring that the cooling system meets the exchanger’s thermal requirements while maintaining energy efficiency.

Leveraging Multi-Objective Optimization Techniques

Real-world heat exchanger design often involves balancing multiple, sometimes competing objectives, such as thermal performance, pressure drop, and material costs. Advanced multi-objective optimization techniques can help engineers find the best compromise solutions, leveraging the power of high-performance computing (HPC) resources.

Several commercial and open-source software packages, including PV Elite, SolidWorks Simulation, ANSYS, and COMSOL Multiphysics, offer powerful optimization capabilities for heat exchanger design. These platforms allow engineers to explore a wide range of design alternatives, evaluate their performance, and identify the most suitable solutions that meet their specific requirements.

Altex Industries’ Approach to Advanced Computational Modeling

At Altex Industries, we recognize the immense value that advanced computational techniques can bring to the design and optimization of shell-and-tube heat exchangers. By combining the power of CFD simulations, FEA modeling, and cutting-edge optimization algorithms, we are able to enhance the performance, efficiency, and reliability of our clients’ heat exchangers.

Our team of experienced engineers leverages a comprehensive suite of computational tools to tackle complex design challenges. From predicting flow patterns and heat transfer rates to assessing structural integrity and identifying optimal configurations, our advanced modeling capabilities enable us to deliver innovative, cost-effective solutions that meet our clients’ specific needs.

Headquartered in Edmonton, Alberta, Altex Industries is strategically positioned to serve a diverse range of industries, including chemical processing, power generation, and oil and gas. Our commitment to leveraging the latest computational advancements ensures that we remain at the forefront of heat exchanger design, helping our clients achieve their energy efficiency and sustainability goals.

If you’re looking to enhance the performance of your shell-and-tube heat exchangers through advanced computational modeling, we encourage you to reach out to the Altex Industries team. Our experts are ready to collaborate with you and unlock the full potential of your equipment.