Exploring the Versatility of Air-Cooled Heat Exchangers in Thermally Activated Building Envelopes

As a seasoned expert in air-cooled heat exchangers, I’m thrilled to delve into the fascinating world of thermally activated building envelopes (TABEs) and their potential applications. In this comprehensive article, we’ll explore the intriguing concept of the sandwich plate system (SPS) and its role as a dynamic building envelope, leveraging the principles of heat transfer to optimize energy efficiency and thermal comfort.

Understanding the Sandwich Plate System (SPS)

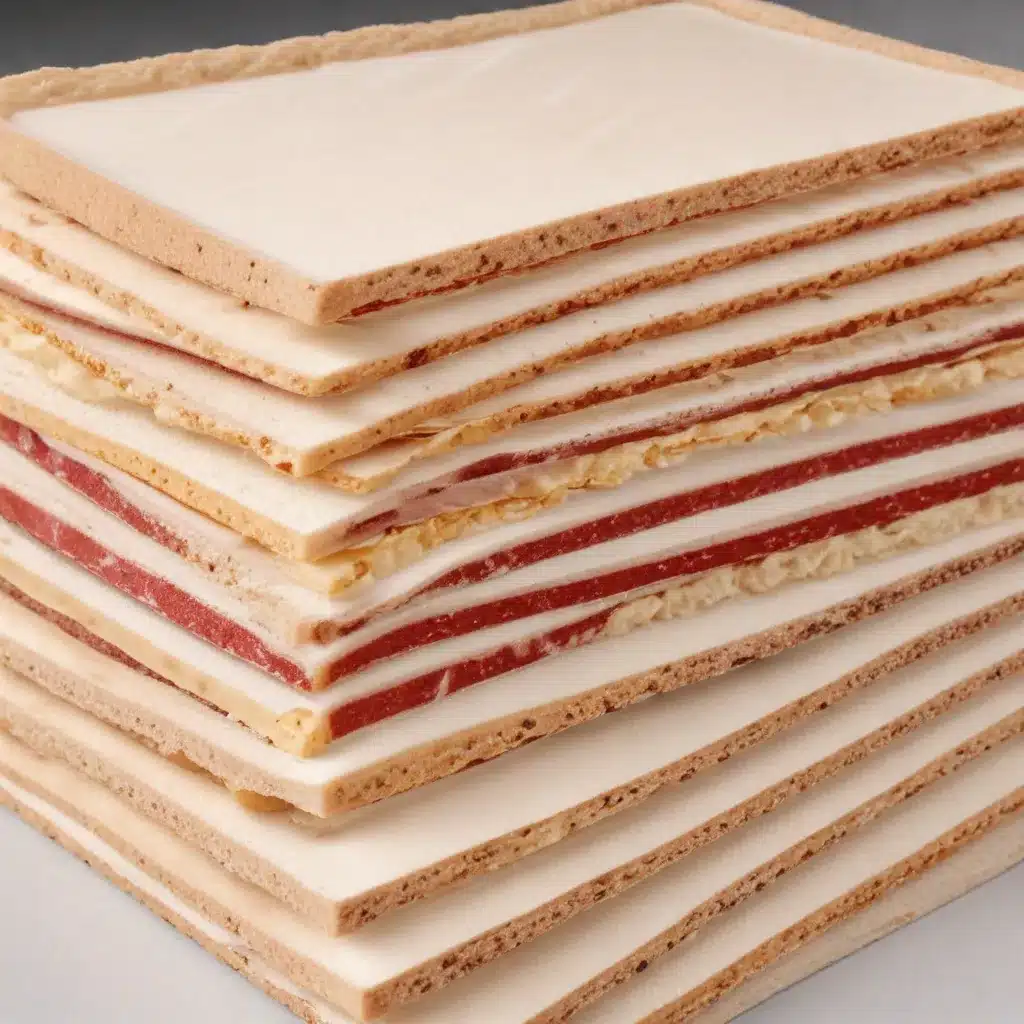

The SPS is a multifunctional building component that seamlessly integrates structural and energy properties. Unlike conventional building envelopes, the SPS is designed to actively manage heat transfer, making it a promising solution for energy-efficient building design.

At the heart of the SPS lies a unique architecture – a set of metal plates strategically arranged with air gaps in between. This configuration allows for the controlled movement of heat, enabling the SPS to function as both a structural element and a thermal regulator.

Harnessing Directional Heat Charging

One of the key features of the SPS is its ability to direct the flow of heat. By incorporating specialized metal fins, the SPS can be designed to optimize the heat charging process, creating a directional thermal barrier that enhances its performance.

Recent research has revealed that an arc-shaped, metal-fin-enhanced TABE (Arc-finTABE) can significantly improve the transient thermal characteristics of the SPS. The strategic placement and design of these fins can influence the size and shape of the thermal energy accumulation area surrounding the embedded pipes, ultimately leading to more effective heat transfer and improved energy efficiency.

Customizing Fin Configurations for Optimal Performance

The research findings suggest that the fin structure plays a crucial role in the SPS’s thermal behavior. By carefully adjusting parameters such as the angle of the main fins, the shank length ratio, and the presence of leftward-mounted fins, the SPS can be tailored to suit different operational modes – load-reduction, auxiliary-heating, or a balanced approach.

For instance, in load-reduction mode, straight main fins with a 30-degree angle, a shank length ratio of 0.4, and no leftward-mounted fins are preferred. This configuration helps to effectively inject heat into the expected areas, reducing the overall heating load.

Conversely, in auxiliary-heating mode, the SPS benefits from main fins with a 150-degree angle, a shank length ratio of 0.8, and multiple fin designs, particularly with one of the main fins pointing horizontally toward the indoor side. This arrangement facilitates the efficient transfer of heat into the building, supplementing the primary heating system.

Moreover, the research suggests that incorporating an arc-shaped branch fin to each main fin can strike a balance between performance improvement and material usage, optimizing the SPS’s overall efficiency.

Reducing Static Insulation Requirements

One of the remarkable advantages of the SPS is its ability to reduce the need for thick static insulation layers while maintaining equivalent thermal performance to conventional high-performance walls.

Under the influence of the strengthened invisible thermal barrier created by the Arc-finTABE, the SPS can achieve a 20-80% reduction in the required static insulation thickness, making it an attractive option for both new construction and retrofit projects.

This finding holds significant implications for the construction industry, as it opens up opportunities to optimize building envelope design, reduce material costs, and enhance overall energy efficiency.

Integrating Low-Grade Heat Sources

The versatility of the SPS extends beyond its thermal management capabilities. Recent studies have explored the integration of low-grade heat sources, such as waste heat or renewable energy, to further enhance the system’s performance.

By leveraging these low-grade heat sources, the SPS can effectively store and distribute thermal energy, reducing the overall energy demand and operating costs of the building. This integration aligns with the broader trend towards sustainable building design and the utilization of renewable or waste heat resources.

Continuous Innovation and Optimization

The research and development surrounding the SPS and its application as a building envelope is an ongoing process, with researchers continuously exploring new avenues for improvement and optimization.

For example, the incorporation of phase change materials (PCMs) into the SPS design has shown promising results in enhancing the system’s thermal storage and release capabilities. By strategically embedding PCMs within the SPS, the building envelope can better regulate temperature fluctuations, providing improved thermal comfort and energy savings.

Additionally, the integration of active control systems, such as model predictive control (MPC) algorithms, has demonstrated the potential to further optimize the operation of the SPS, ensuring optimal energy performance while maintaining occupant comfort.

Conclusion: The Future of Thermally Activated Building Envelopes

The SPS, as a versatile and thermally activated building envelope, represents a promising solution for the ever-evolving challenges of energy-efficient building design. By harnessing the principles of heat transfer and leveraging the capabilities of air-cooled heat exchangers, the SPS offers a multifunctional approach to building envelope design, seamlessly integrating structural integrity and energy optimization.

As the industry continues to push the boundaries of sustainable construction, the SPS and its innovative applications will undoubtedly play a crucial role in shaping the future of thermally activated building envelopes. Through ongoing research, development, and real-world implementation, the SPS has the potential to transform the way we design, construct, and operate our built environment, ultimately leading to a more energy-efficient and comfortable living and working spaces.

Exploring the Versatility of Air-Cooled Heat Exchangers in Thermally Activated Building Envelopes

As a seasoned expert in air-cooled heat exchangers, I’m thrilled to delve into the fascinating world of thermally activated building envelopes (TABEs) and their potential applications. In this comprehensive article, we’ll explore the intriguing concept of the sandwich plate system (SPS) and its role as a dynamic building envelope, leveraging the principles of heat transfer to optimize energy efficiency and thermal comfort.

Understanding the Sandwich Plate System (SPS)

The SPS is a multifunctional building component that seamlessly integrates structural and energy properties. Unlike conventional building envelopes, the SPS is designed to actively manage heat transfer, making it a promising solution for energy-efficient building design.

At the heart of the SPS lies a unique architecture – a set of metal plates strategically arranged with air gaps in between. This configuration allows for the controlled movement of heat, enabling the SPS to function as both a structural element and a thermal regulator.

Harnessing Directional Heat Charging

One of the key features of the SPS is its ability to direct the flow of heat. By incorporating specialized metal fins, the SPS can be designed to optimize the heat charging process, creating a directional thermal barrier that enhances its performance.

Recent research has revealed that an arc-shaped, metal-fin-enhanced TABE (Arc-finTABE) can significantly improve the transient thermal characteristics of the SPS. The strategic placement and design of these fins can influence the size and shape of the thermal energy accumulation area surrounding the embedded pipes, ultimately leading to more effective heat transfer and improved energy efficiency.

Customizing Fin Configurations for Optimal Performance

The research findings suggest that the fin structure plays a crucial role in the SPS’s thermal behavior. By carefully adjusting parameters such as the angle of the main fins, the shank length ratio, and the presence of leftward-mounted fins, the SPS can be tailored to suit different operational modes – load-reduction, auxiliary-heating, or a balanced approach.

For instance, in load-reduction mode, straight main fins with a 30-degree angle, a shank length ratio of 0.4, and no leftward-mounted fins are preferred. This configuration helps to effectively inject heat into the expected areas, reducing the overall heating load.

Conversely, in auxiliary-heating mode, the SPS benefits from main fins with a 150-degree angle, a shank length ratio of 0.8, and multiple fin designs, particularly with one of the main fins pointing horizontally toward the indoor side. This arrangement facilitates the efficient transfer of heat into the building, supplementing the primary heating system.

Moreover, the research suggests that incorporating an arc-shaped branch fin to each main fin can strike a balance between performance improvement and material usage, optimizing the SPS’s overall efficiency.

Reducing Static Insulation Requirements

One of the remarkable advantages of the SPS is its ability to reduce the need for thick static insulation layers while maintaining equivalent thermal performance to conventional high-performance walls.

Under the influence of the strengthened invisible thermal barrier created by the Arc-finTABE, the SPS can achieve a 20-80% reduction in the required static insulation thickness, making it an attractive option for both new construction and retrofit projects.

This finding holds significant implications for the construction industry, as it opens up opportunities to optimize building envelope design, reduce material costs, and enhance overall energy efficiency.

Integrating Low-Grade Heat Sources

The versatility of the SPS extends beyond its thermal management capabilities. Recent studies have explored the integration of low-grade heat sources, such as waste heat or renewable energy, to further enhance the system’s performance.

By leveraging these low-grade heat sources, the SPS can effectively store and distribute thermal energy, reducing the overall energy demand and operating costs of the building. This integration aligns with the broader trend towards sustainable building design and the utilization of renewable or waste heat resources.

Continuous Innovation and Optimization

The research and development surrounding the SPS and its application as a building envelope is an ongoing process, with researchers continuously exploring new avenues for improvement and optimization.

For example, the incorporation of phase change materials (PCMs) into the SPS design has shown promising results in enhancing the system’s thermal storage and release capabilities. By strategically embedding PCMs within the SPS, the building envelope can better regulate temperature fluctuations, providing improved thermal comfort and energy savings.

Additionally, the integration of active control systems, such as model predictive control (MPC) algorithms, has demonstrated the potential to further optimize the operation of the SPS, ensuring optimal energy performance while maintaining occupant comfort.

Conclusion: The Future of Thermally Activated Building Envelopes

The SPS, as a versatile and thermally activated building envelope, represents a promising solution for the ever-evolving challenges of energy-efficient building design. By harnessing the principles of heat transfer and leveraging the capabilities of air-cooled heat exchangers, the SPS offers a multifunctional approach to building envelope design, seamlessly integrating structural integrity and energy optimization.

As the industry continues to push the boundaries of sustainable construction, the SPS and its innovative applications will undoubtedly play a crucial role in shaping the future of thermally activated building envelopes. Through ongoing research, development, and real-world implementation, the SPS has the potential to transform the way we design, construct, and operate our built environment, ultimately leading to more energy-efficient and comfortable living and working spaces.

At Air Cooled Heat Exchangers, we are committed to providing our readers with the latest insights and practical solutions in the realm of air-cooled heat exchangers and their versatile applications. The SPS, as a cutting-edge building envelope technology, exemplifies the power of innovative thinking and the integration of thermal management principles. We encourage you to explore the resources available on our website to further delve into the world of air-cooled heat exchangers and their transformative potential in the built environment.