The Evolving Landscape of Air-Cooled Heat Exchangers: Navigating Challenges and Unlocking Opportunities

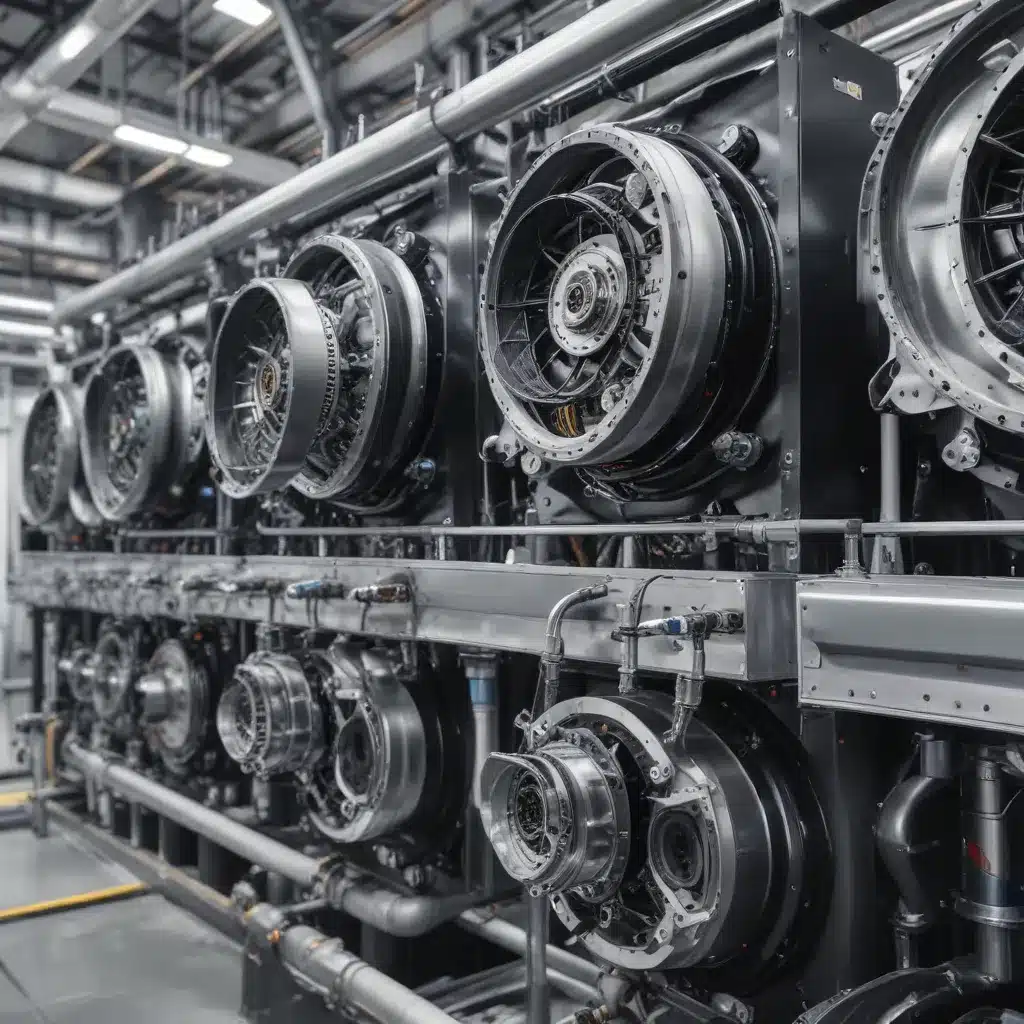

Air-cooled heat exchangers are essential components in a wide range of industrial applications, from power generation to petrochemical processing, playing a crucial role in managing thermal energy and improving system efficiency. As the demand for these critical assets continues to grow, the need for advanced maintenance strategies has become paramount. Conventional maintenance approaches, often relying on reactive or time-based methods, have proven insufficient in addressing the complex challenges faced by modern air-cooled heat exchanger systems.

Fortunately, the advent of Artificial Intelligence (AI) and Machine Learning (ML) has ushered in a transformative era, empowering engineers and maintenance professionals to tackle these challenges head-on. By harnessing the power of AI-driven predictive maintenance, fault detection, and performance optimization, the industry is poised to enhance the reliability, efficiency, and longevity of air-cooled heat exchangers across diverse applications.

Air-Cooled Heat Exchangers are widely used in various industries, including power generation, petrochemical processing, manufacturing, and HVAC systems. These heat exchangers play a crucial role in transferring heat from one fluid to another, often using air as the cooling medium. However, the operation and maintenance of air-cooled heat exchangers can be complex, with factors such as fouling, corrosion, and mechanical wear posing significant challenges.

Embracing the AI Revolution in Air-Cooled Heat Exchanger Maintenance

The integration of AI and ML techniques has revolutionized the way we approach the maintenance and optimization of air-cooled heat exchangers. By leveraging these advanced technologies, organizations can now anticipate and prevent equipment failures, optimize system performance, and minimize unplanned downtime, ultimately enhancing the overall reliability and cost-effectiveness of their air-cooled heat exchanger assets.

Predictive Maintenance: Proactively Addressing Equipment Failures

Predictive maintenance (PdM) is a game-changing approach that harnesses the power of AI and ML to predict equipment failures before they occur. By continuously monitoring the condition of air-cooled heat exchangers, PdM systems can detect early signs of degradation, enabling timely interventions and preventive maintenance actions.

AI-powered PdM leverages various sensor data, such as vibration, temperature, and pressure readings, to develop predictive models that can forecast the remaining useful life (RUL) of critical components. These models utilize techniques like Artificial Neural Networks (ANNs), Convolutional Neural Networks (CNNs), and Long Short-Term Memory (LSTMs) to identify patterns and anomalies within the data, accurately predicting when maintenance actions should be performed.

By implementing PdM, organizations can optimize maintenance schedules, reduce the risk of unplanned outages, and extend the lifespan of air-cooled heat exchangers. This proactive approach not only enhances equipment reliability but also minimizes the financial impact of unexpected failures, leading to significant cost savings and improved operational efficiency.

Intelligent Fault Detection: Identifying and Addressing Issues in Real-Time

Alongside predictive maintenance, AI-driven fault detection systems play a crucial role in ensuring the optimal performance of air-cooled heat exchangers. These advanced systems integrate a variety of sensors and monitoring techniques to identify and diagnose issues in real-time, enabling rapid response and effective troubleshooting.

Intelligent fault detection leverages computer vision, acoustic analysis, and multi-sensor data fusion to detect a wide range of anomalies, such as tube leaks, fouling, and component failures. By applying techniques like Support Vector Machines (SVMs), Decision Trees, and Random Forests, these systems can accurately classify and locate the root causes of equipment malfunctions, empowering maintenance teams to take corrective actions swiftly.

Moreover, the integration of AI and ML into air-cooled heat exchanger monitoring systems enables predictive analytics, allowing organizations to anticipate potential issues and proactively address them before they escalate. This proactive approach not only minimizes equipment downtime but also enhances the overall reliability and performance of the heat exchanger systems.

Performance Optimization: Maximizing Efficiency and Productivity

Beyond predictive maintenance and fault detection, AI and ML techniques have also revolutionized the optimization of air-cooled heat exchanger performance. By leveraging advanced analytics, these technologies can identify opportunities for improving energy efficiency, thermal management, and overall system productivity.

AI-powered optimization involves the use of techniques like Genetic Algorithms, Reinforcement Learning, and Multi-Objective Optimization to fine-tune critical parameters, such as air-flow rates, fan speeds, and heat transfer coefficients. These algorithms can analyze vast amounts of operational data, including environmental conditions, equipment characteristics, and energy consumption, to identify the optimal configuration for maximizing the performance and efficiency of air-cooled heat exchangers.

By implementing AI-driven optimization, organizations can reduce energy costs, optimize the utilization of their assets, and enhance the overall productivity of their air-cooled heat exchanger systems. This data-driven approach enables continuous improvement, ensuring that these critical components operate at their peak efficiency throughout their lifespan.

The Future of Air-Cooled Heat Exchanger Maintenance: Embracing the AI-Driven Transformation

As the air-cooled heat exchanger industry continues to evolve, the integration of AI and ML technologies will become increasingly crucial in addressing the challenges faced by maintenance professionals and engineers. By harnessing the power of predictive analytics, intelligent fault detection, and performance optimization, organizations can unlock a new era of reliability, efficiency, and cost-effectiveness in the management of their air-cooled heat exchanger assets.

The Air-Cooled Heat Exchangers blog is committed to providing the latest insights, practical tips, and in-depth analysis on the transformative role of AI and ML in this critical field. Through the seamless integration of these advanced technologies, the industry can look forward to a future where air-cooled heat exchangers operate at their peak performance, minimizing downtime, optimizing energy consumption, and delivering lasting value to the organizations that rely on them.