The Evolution of Air-Cooled Heat Exchanger Design and Performance

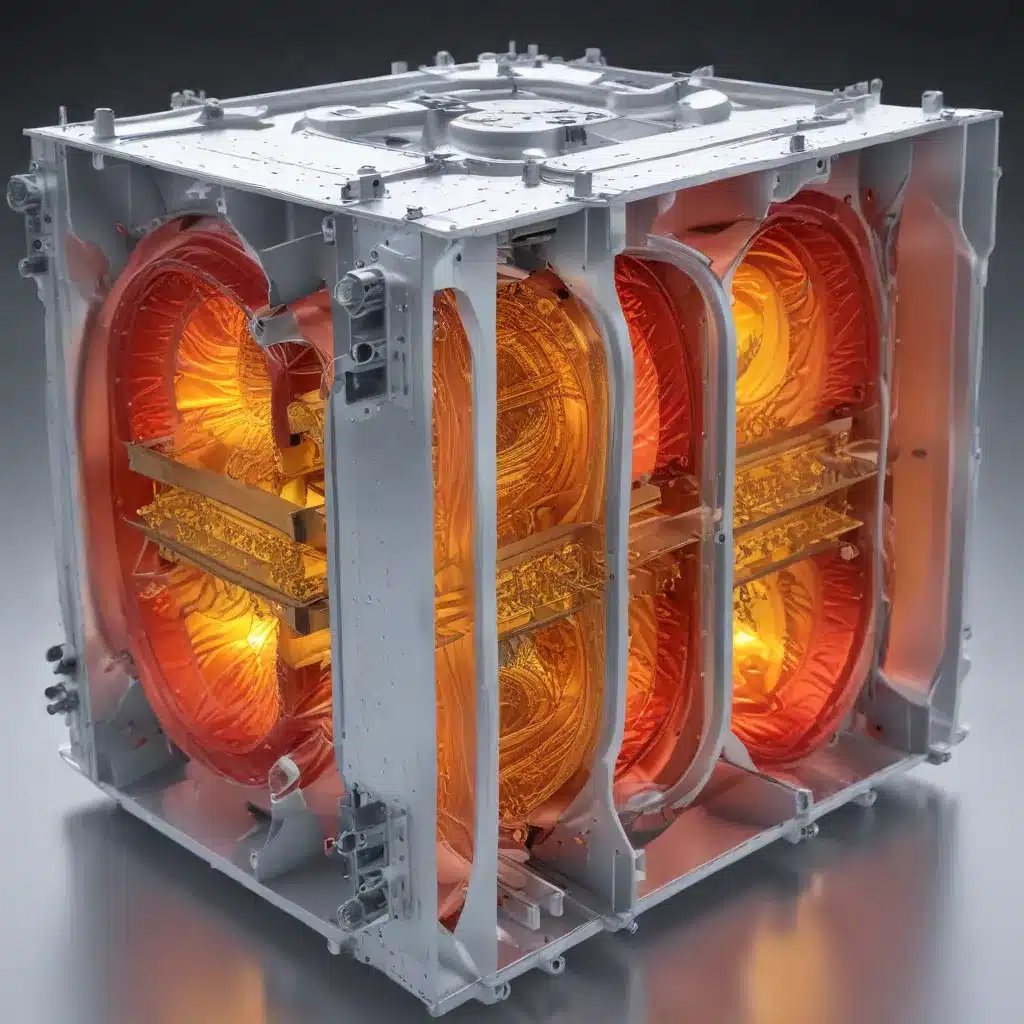

Air-cooled heat exchangers play a pivotal role in a wide range of industries, from power generation and manufacturing to HVAC systems and electronics cooling. As technological advancements continue to push the boundaries of product complexity and performance demands, the design and engineering of these critical thermal management components have become increasingly sophisticated. Simulation and computational fluid dynamics (CFD) have emerged as indispensable tools in the arsenal of heat exchanger experts, enabling them to tackle the growing complexities and deliver innovative solutions.

In the past, the design of air-cooled heat exchangers was often based on empirical correlations and simplified models, relying heavily on physical prototyping and testing. While this approach provided a functional starting point, it lacked the depth and flexibility to address the multifaceted challenges faced by modern heat exchanger applications. The advent of multiphysics simulation, however, has transformed the landscape, empowering engineers to explore and optimize air-cooled heat exchanger designs in ways that were previously unimaginable.

The Power of Multiphysics Simulation and CFD

Multiphysics simulation tools, such as Simcenter STAR-CCM+, integrate a comprehensive suite of computational fluid dynamics capabilities that allow engineers to model and analyze the intricate interactions between various physical phenomena. This holistic approach is crucial for accurately predicting the real-world performance of air-cooled heat exchangers, which often involve complex fluid flow, heat transfer, and even structural dynamics.

“Simcenter STAR-CCM+ enables us to simulate the complexity and explore the possibilities of products operating under real-world conditions,” explains a seasoned CFD engineer. “By integrating a wide range of physics, including fluid dynamics, heat transfer, multiphase flows, particle dynamics, and more, we can create highly accurate digital representations of air-cooled heat exchanger systems.”

Bridging the Gap from Design to Performance

One of the key advantages of multiphysics simulation is its ability to bridge the gap between the design and performance of air-cooled heat exchangers. Traditional design approaches often relied on simplistic assumptions and empirical correlations, which could lead to suboptimal or even flawed designs. Multiphysics simulation, on the other hand, enables engineers to accurately model the complex interplay of fluid flow, heat transfer, and structural mechanics, ensuring that the final design will perform as intended in real-world operating conditions.

“With Simcenter STAR-CCM+, we can quickly move from multi-CAD geometry data to a complete, run-ready analysis model,” says a heat exchanger design expert. “The software’s automated meshing and pre-processing capabilities allow us to spend more time evaluating results and exploring design possibilities, rather than getting bogged down in lengthy preparation tasks.”

Pushing the Boundaries of Air-Cooled Heat Exchanger Performance

Multiphysics simulation empowers heat exchanger engineers to explore innovative design concepts and push the boundaries of performance. By simulating the effects of various parameters, such as fin geometry, tube arrangements, and air flow patterns, engineers can optimize heat transfer efficiency, minimize pressure drops, and enhance overall system performance.

“The ability to simulate a wide range of physics, from fluid dynamics to particle dynamics and beyond, allows us to tackle even the most complex air-cooled heat exchanger applications,” explains a thermal systems expert. “We can model the impact of factors like fouling, vibrations, and structural fatigue, ensuring that our designs not only perform well but also maintain their efficiency over the long term.”

Driving Innovation through Design Exploration and Optimization

Multiphysics simulation, when combined with advanced design exploration and optimization techniques, becomes a powerful tool for innovation. Simulation-driven design workflows enable engineers to rapidly evaluate multiple design iterations, identify the most promising concepts, and fine-tune them to achieve optimal performance.

“With the design exploration capabilities in Simcenter STAR-CCM+, we can efficiently explore hundreds of design variations and find the best solution,” says a heat exchanger design engineer. “The ability to automate simulation workflows and leverage advanced optimization algorithms has significantly accelerated our innovation process, allowing us to bring better products to market faster.”

Streamlining the Development Process

Multiphysics simulation and CFD also play a crucial role in streamlining the overall development process for air-cooled heat exchangers. By providing accurate virtual prototypes, engineers can reduce the need for physical testing, saving time and resources. Additionally, the ability to quickly assess the impact of design changes and identify performance bottlenecks early in the design phase helps to minimize costly design iterations and rework.

“Simcenter STAR-CCM+ has been instrumental in our ability to accurately predict the performance of our air-cooled heat exchangers,” notes a heat exchanger manufacturer. “The tight integration with CAD and the seamless pre-processing capabilities have allowed us to drastically reduce the time we spend preparing models for simulation, enabling us to focus on optimizing the designs.”

Advancing Air-Cooled Heat Exchanger Applications

The advancements in multiphysics simulation and CFD have opened up new frontiers for air-cooled heat exchanger applications, enabling engineers to tackle increasingly complex thermal management challenges.

Electronics Cooling

In the realm of electronics cooling, the demand for more compact and efficient heat dissipation solutions has driven the need for sophisticated simulation tools. Simcenter STAR-CCM+ provides a comprehensive suite of capabilities for modeling the intricate fluid flow and heat transfer dynamics within electronic enclosures, printed circuit boards, and chip-level packages, allowing for the optimization of air-cooled heat sink and heat exchanger designs.

“As the power density of electronic components continues to increase, we rely on Simcenter STAR-CCM+ to accurately predict the thermal performance of our air-cooled heat exchangers,” explains an electronics cooling specialist. “The software’s ability to model conduction, convection, and radiation allows us to design highly effective thermal management solutions that keep our clients’ critical systems running at peak performance.”

Industrial Process Cooling

In industrial settings, air-cooled heat exchangers play a vital role in temperature control and process efficiency. Multiphysics simulation enables engineers to optimize the design of these heat exchangers for a wide range of applications, from power generation and manufacturing to chemical processing and waste management.

“Simcenter STAR-CCM+ has been instrumental in helping us design and optimize air-cooled heat exchangers for our industrial process cooling systems,” says a thermal engineer. “By accurately modeling the complex fluid dynamics and heat transfer within these systems, we can ensure optimal performance, minimize energy consumption, and reduce maintenance requirements.”

Renewable Energy Systems

The growing adoption of renewable energy technologies, such as wind turbines and solar power plants, has also brought about new challenges in air-cooled heat exchanger design. Multiphysics simulation tools like Simcenter STAR-CCM+ allow engineers to model the intricate interactions between the heat exchanger, the surrounding environment, and the renewable energy system as a whole, leading to more efficient and reliable thermal management solutions.

“As we work to advance the performance and sustainability of our renewable energy systems, Simcenter STAR-CCM+ has become an indispensable tool,” explains a renewable energy engineer. “The software’s ability to simulate multiphase flows, particle dynamics, and fluid-structure interactions has been crucial in optimizing the air-cooled heat exchangers that play a critical role in maintaining the efficiency and reliability of our wind turbines and solar power plants.”

Embracing the Future of Air-Cooled Heat Exchanger Design

As the demands on thermal management systems continue to grow, the role of multiphysics simulation and computational fluid dynamics in air-cooled heat exchanger design will only become more pivotal. By leveraging the power of these advanced simulation tools, engineers can unlock new levels of performance, efficiency, and sustainability, paving the way for innovative, cutting-edge thermal management solutions.

“The future of air-cooled heat exchanger design is inextricably linked to the advancements in multiphysics simulation and CFD,” concludes a thermal systems expert. “As we strive to meet the ever-evolving challenges of our industries, these simulation tools will continue to be the driving force behind the development of smarter, more reliable, and more sustainable thermal management systems.”