In the ever-evolving landscape of thermal management solutions, air-cooled heat exchangers have long played a crucial role in a wide range of industries, from HVAC systems to data centers. As the demand for efficient and reliable cooling systems continues to grow, researchers and engineers have turned their attention to the potential of microfluidics to enhance the thermal performance of these essential components.

The Challenge of Thermal Management in Air-Cooled Heat Exchangers

Air-cooled heat exchangers rely on the natural convection of air to dissipate heat from various systems and applications. However, as the heat loads and power densities continue to increase, traditional air-cooling methods struggle to keep up with the growing thermal management demands. This challenge has led to the exploration of innovative solutions that can enhance the heat transfer capabilities of air-cooled heat exchangers.

The Limitations of Conventional Air-Cooling Techniques

Conventional air-cooling techniques, such as finned-tube or plate-fin heat exchangers, have inherent limitations in their ability to dissipate high heat fluxes. The relatively low thermal conductivity and heat transfer coefficient of air, combined with the geometric constraints of traditional designs, can result in insufficient cooling capacity and potential hotspots within the system.

The Emergence of Microfluidics as a Solution

Microfluidics, the study and manipulation of fluids at the microscale, has emerged as a promising field for addressing the thermal management challenges faced by air-cooled heat exchangers. By incorporating microfluidic features and principles into the design and operation of these heat exchangers, researchers have been able to significantly improve their thermal performance and overcome the limitations of conventional air-cooling techniques.

Leveraging Microfluidics for Enhanced Thermal Performance

The integration of microfluidics into air-cooled heat exchangers has opened up new avenues for thermal management optimization. By harnessing the unique characteristics of fluids at the microscale, engineers can design heat exchanger systems that exhibit enhanced heat transfer capabilities, improved energy efficiency, and superior reliability.

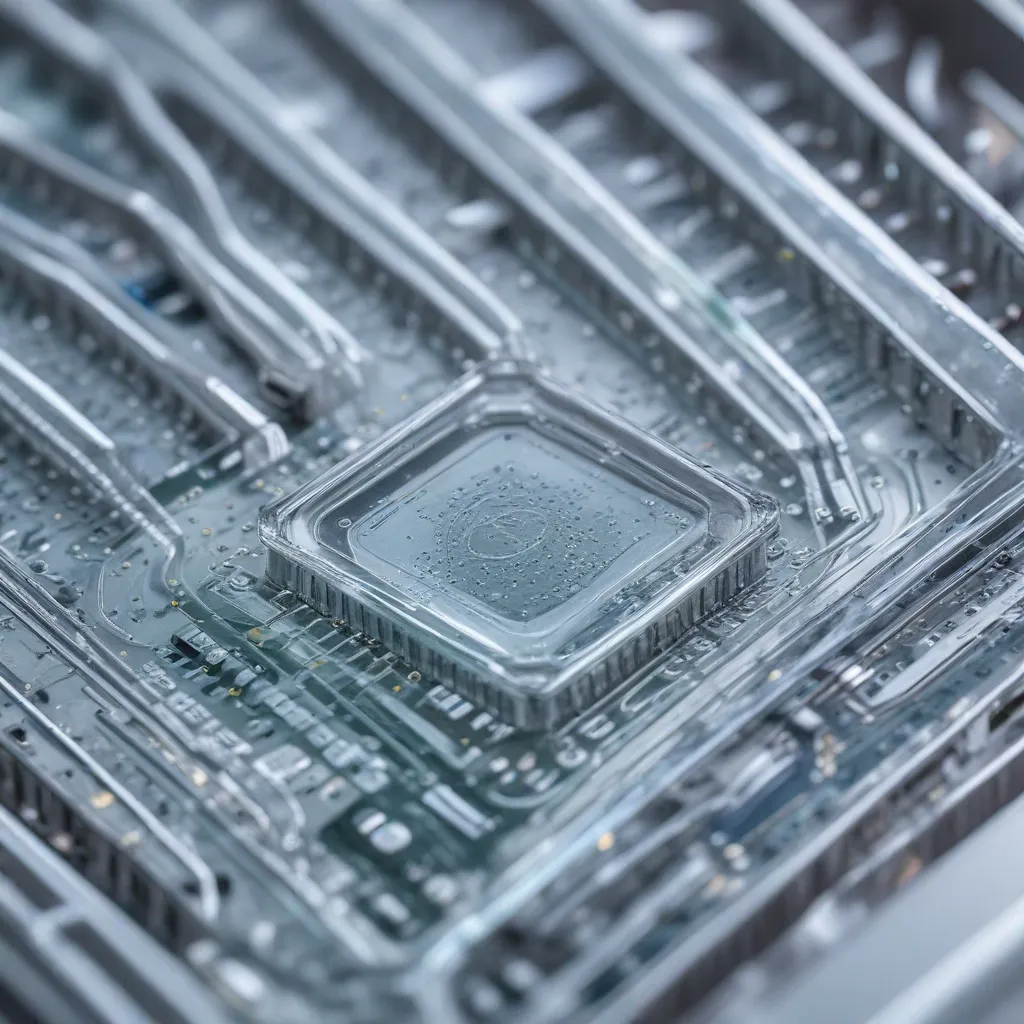

Microchannel Heat Exchangers

One of the key applications of microfluidics in air-cooled heat exchangers is the development of microchannel heat exchangers. These heat exchangers incorporate a network of microscale channels, often just a few hundred micrometers in diameter, that allow for the circulation of a cooling fluid in close proximity to the heat source. The high surface-to-volume ratio and the enhanced heat transfer coefficients achieved in these microchannels can significantly improve the overall thermal performance of the heat exchanger.

Microjet Impingement Cooling

Another microfluidic-based approach to enhancing the thermal performance of air-cooled heat exchangers is the use of microjet impingement cooling. In this technique, a series of microscale jets or nozzles are used to direct a concentrated flow of cooling fluid onto the targeted hot spots or high-heat-flux regions within the heat exchanger. This localized and high-intensity cooling can effectively dissipate the concentrated heat, leading to a more uniform temperature distribution and improved overall thermal management.

Micro-Pin Fin Heat Exchangers

Micro-pin fin heat exchangers incorporate an array of microscale pin fins or pillars within the heat exchanger channels or surfaces. These micro-pin fins, typically ranging from 100 to 500 micrometers in size, can significantly increase the surface area for heat transfer, while also promoting turbulent flow and enhanced convective heat transfer. The strategic placement and optimization of these micro-pin fins can result in substantial improvements in the thermal performance of air-cooled heat exchangers.

Microfluidic Cooling Strategies

In addition to the specific microfluidic heat exchanger designs, researchers have also explored various microfluidic cooling strategies to enhance the thermal performance of air-cooled heat exchangers. These strategies include the use of phase-change materials, electrohydrodynamic (EHD) cooling, and the integration of microfluidic heat sinks or cold plates within the overall heat exchanger system.

Overcoming Challenges and Optimizing Microfluidic Heat Exchangers

While the potential of microfluidics in improving the thermal performance of air-cooled heat exchangers is evident, the implementation of these technologies is not without its challenges. Engineers and researchers have been working diligently to address these challenges and optimize the design and operation of microfluidic-based heat exchangers.

Addressing Fabrication and Scalability Challenges

One of the key challenges in the widespread adoption of microfluidic heat exchangers is the complexity and cost associated with their fabrication. Techniques such as micromachining, laser micromachining, or additive manufacturing are often required to produce the intricate microfluidic features. Overcoming these fabrication hurdles and developing scalable manufacturing processes are crucial for making microfluidic heat exchangers more accessible and cost-effective.

Optimizing Fluid Flow and Heat Transfer Characteristics

Ensuring efficient and uniform fluid flow through the microscale channels and features is another critical aspect of microfluidic heat exchanger design. Researchers have explored various strategies, including the use of microstructured surfaces, flow-guiding elements, and advanced fluid dynamic modeling, to optimize the fluid flow and heat transfer characteristics within these systems.

Addressing Reliability and Maintenance Concerns

Reliability and maintenance are also important considerations when implementing microfluidic heat exchangers in real-world applications. Factors such as fouling, clogging, and the potential for leaks must be carefully addressed through innovative design approaches and the development of robust maintenance protocols.

Integrating Microfluidics into Larger Systems

As air-cooled heat exchangers are often part of larger thermal management systems, the seamless integration of microfluidic-based heat exchangers into these systems is crucial. Ensuring compatibility, efficient heat transfer between components, and overall system optimization are all important aspects that require careful consideration.

The Future of Microfluidics in Air-Cooled Heat Exchangers

The integration of microfluidics into air-cooled heat exchangers holds immense promise for the future of thermal management solutions. As researchers and engineers continue to push the boundaries of this technology, we can expect to see even greater advancements in the thermal performance, energy efficiency, and reliability of these critical components.

Emerging Applications and Industry Adoption

The potential applications of microfluidic-enhanced air-cooled heat exchangers span a wide range of industries, from data centers and electronics cooling to industrial processing and transportation. As the demand for efficient and high-performance thermal management solutions grows, the adoption of these technologies is likely to accelerate across various sectors.

Synergies with Other Emerging Technologies

The evolution of microfluidic heat exchangers is not happening in isolation. The field is closely intertwined with other emerging technologies, such as advanced materials, additive manufacturing, and the Internet of Things (IoT). The integration of these complementary technologies can further enhance the capabilities and benefits of microfluidic-based air-cooled heat exchangers.

Continuous Research and Development

Ongoing research and development efforts in the field of microfluidics and thermal engineering will undoubtedly lead to even more innovative and transformative solutions for air-cooled heat exchangers. Collaboration between academia, industry, and regulatory bodies will be crucial in driving the continued advancement and widespread adoption of these technologies.

As the air-cooled heat exchanger industry continues to evolve, the integration of microfluidics promises to be a game-changer, unlocking new levels of thermal performance, energy efficiency, and reliability. By embracing this transformative technology, engineers and industry leaders can position themselves at the forefront of the thermal management revolution.

To learn more about the latest advancements in air-cooled heat exchangers and how your organization can benefit from these technologies, please visit our website at https://www.aircooledheatexchangers.net/.