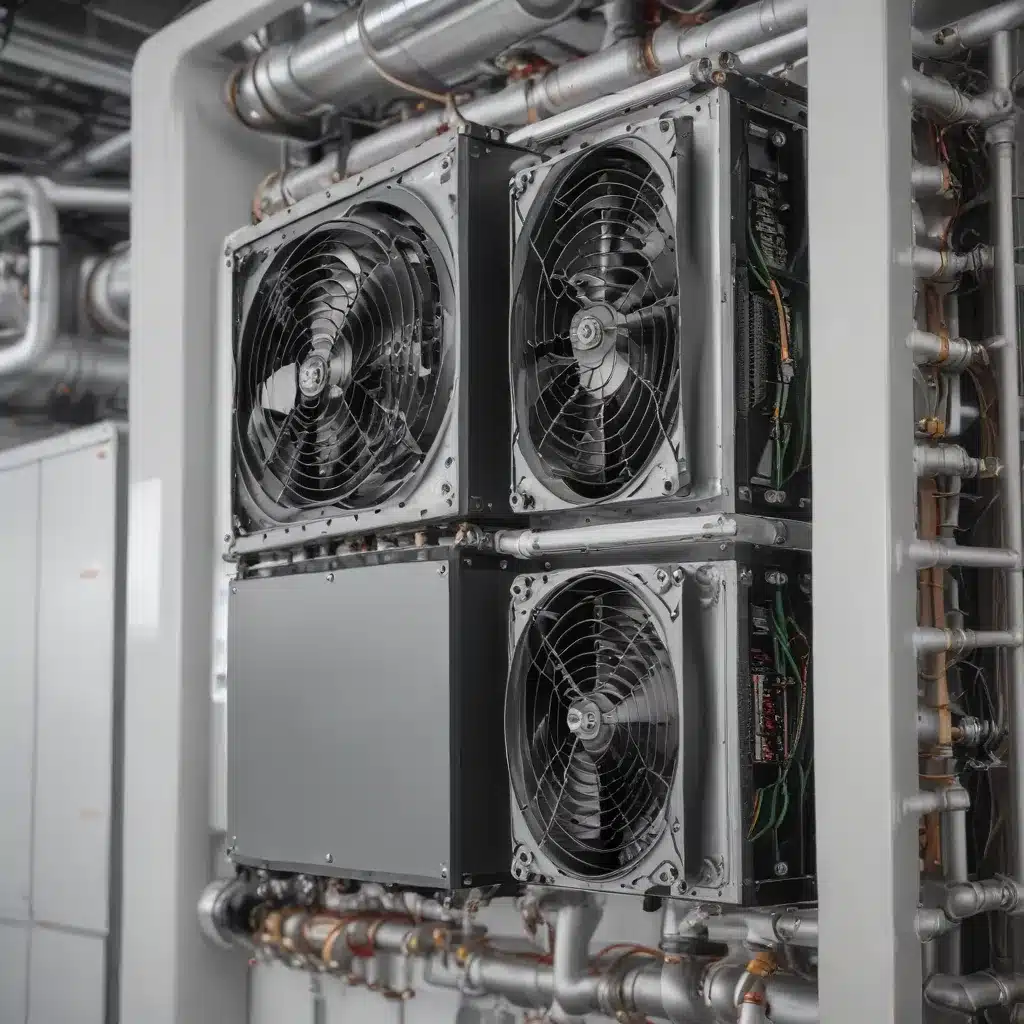

The Evolving Landscape of Air-Cooled Heat Exchangers

Air-cooled heat exchangers have long been a staple in industrial and commercial applications, playing a crucial role in efficiently transferring thermal energy. However, as technology continues to advance, the landscape of air-cooled heat exchanger management is undergoing a transformative shift. The integration of cutting-edge control systems and the Internet of Things (IoT) is unlocking new possibilities for optimizing the performance, efficiency, and maintenance of these essential heat transfer devices.

Harnessing the Power of Advanced Control Systems

Traditional air-cooled heat exchanger management often relied on manual adjustments, reactive maintenance, and basic control systems. Today, the landscape is evolving rapidly, with the emergence of sophisticated control systems that can proactively manage and optimize heat exchanger operations. These advanced control systems leverage sophisticated algorithms, real-time data analytics, and adaptive control strategies to achieve unprecedented levels of efficiency and reliability.

Key features of modern air-cooled heat exchanger control systems include:

-

Predictive Maintenance: By continuously monitoring critical parameters such as vibration, temperature, and pressure, these control systems can detect early warning signs of potential issues. This allows for timely maintenance interventions, reducing the risk of unexpected downtime and extending the overall lifespan of the heat exchangers.

-

Automated Optimization: Advanced control algorithms can dynamically adjust operating parameters, such as fan speed, airflow, and coolant flow, to maintain optimal heat transfer efficiency. This adaptive approach ensures that the heat exchangers operate at peak performance, regardless of changing environmental conditions or process requirements.

-

Integrated Diagnostics: Comprehensive monitoring and diagnostics capabilities provide valuable insights into the health and performance of air-cooled heat exchangers. By analyzing trends and identifying anomalies, operators can make informed decisions about maintenance, upgrades, or system modifications.

-

Remote Monitoring and Control: Many of these control systems offer remote access and control capabilities, enabling operators to monitor and manage air-cooled heat exchangers from anywhere, reducing the need for on-site personnel and enhancing operational flexibility.

Leveraging the Internet of Things (IoT) for Intelligent Heat Exchanger Management

The integration of IoT technology with air-cooled heat exchangers further amplifies the potential for intelligent management and optimization. By connecting heat exchangers to the IoT ecosystem, operators can unlock a wealth of data-driven insights and intelligent control capabilities.

Key IoT-enabled features for air-cooled heat exchanger management include:

-

Comprehensive Data Acquisition: IoT-enabled sensors and devices can capture a vast array of operational data, including temperatures, pressures, vibrations, and environmental conditions. This real-time data stream provides a comprehensive view of the heat exchanger’s performance and health.

-

Predictive Maintenance and Optimization: By leveraging advanced analytics and machine learning algorithms, IoT-based systems can identify patterns, predict potential failures, and optimize operating parameters to maximize efficiency and minimize downtime.

-

Seamless Integration and Connectivity: IoT platforms facilitate the integration of air-cooled heat exchangers with other industrial systems, enabling cross-functional data sharing, centralized monitoring, and coordinated control across the entire facility or enterprise.

-

Intelligent Alerts and Notifications: IoT-enabled systems can provide timely alerts and notifications, informing operators of critical events, anomalies, or the need for maintenance, allowing for proactive decision-making and rapid response.

-

Scalable and Flexible Architecture: The modular and scalable nature of IoT-based systems allows for the easy integration of new heat exchangers, sensors, and control devices, ensuring that the management solution can adapt to changing needs and accommodate future growth.

Unlocking the Benefits of Advanced Control and IoT for Air-Cooled Heat Exchangers

By harnessing the power of advanced control systems and IoT technology, organizations operating air-cooled heat exchangers can unlock a myriad of benefits that drive enhanced performance, efficiency, and cost-effectiveness.

Improved Operational Efficiency

The combination of predictive maintenance, automated optimization, and real-time data analytics enabled by these advanced systems can lead to significant improvements in the overall operational efficiency of air-cooled heat exchangers. Optimized fan speeds, airflow, and coolant management can minimize energy consumption, while proactive maintenance strategies reduce the risk of unplanned downtime and extend the lifespan of the equipment.

Enhanced Reliability and Uptime

Intelligent monitoring, fault detection, and adaptive control capabilities provided by these systems help maintain the optimal performance of air-cooled heat exchangers. By anticipating and addressing potential issues before they escalate, operators can minimize the occurrence of breakdowns and ensure a more reliable and uninterrupted operation of critical heat transfer processes.

Cost Savings and Reduced Maintenance Burden

Advanced control and IoT-enabled systems can lead to substantial cost savings by reducing energy consumption, extending equipment life, and optimizing maintenance schedules. The data-driven insights and predictive maintenance capabilities allow operators to transition from a reactive to a proactive maintenance approach, minimizing the need for costly emergency repairs and unplanned downtime.

Improved Sustainability and Environmental Impact

Air-cooled heat exchangers play a vital role in energy-intensive industries, and the optimization of their performance can have a significant impact on environmental sustainability. By improving energy efficiency and reducing greenhouse gas emissions, these advanced systems contribute to the overall environmental stewardship of the organizations that implement them.

Implementing Advanced Control and IoT for Air-Cooled Heat Exchangers

Integrating advanced control systems and IoT technology into air-cooled heat exchanger management requires a strategic and well-planned approach. Organizations should consider the following key steps to ensure a successful implementation:

-

Assess Current Infrastructure and Capabilities: Evaluate the existing air-cooled heat exchanger systems, control mechanisms, and data management capabilities. This assessment will help identify areas for improvement and guide the selection of appropriate advanced control and IoT solutions.

-

Develop a Comprehensive Integration Plan: Design a detailed roadmap for the integration of advanced control and IoT technologies, including the selection of compatible hardware and software, data connectivity and security requirements, and the implementation of necessary infrastructure upgrades.

-

Leverage Expert Guidance and Support: Collaborate with experienced air-cooled heat exchanger manufacturers, system integrators, or industry experts to ensure the successful deployment and optimization of the advanced control and IoT systems.

-

Prioritize Data Analytics and Reporting: Invest in robust data analytics capabilities to extract valuable insights from the wealth of operational data generated by the IoT-enabled heat exchangers. Develop comprehensive reporting and visualization tools to support data-driven decision-making.

-

Foster a Culture of Continuous Improvement: Encourage a mindset of constant optimization and refinement within the organization. Regularly review the performance of the advanced control and IoT systems, and implement incremental improvements to enhance efficiency, reliability, and sustainability.

By embracing the power of advanced control systems and IoT technology, organizations can transform the way they manage and optimize their air-cooled heat exchangers, unlocking new levels of efficiency, reliability, and cost-effectiveness. As the industry continues to evolve, these cutting-edge solutions will play a pivotal role in shaping the future of thermal management and drive the air-cooled heat exchanger industry forward.