The Rise of Additive Manufacturing in Thermal Engineering

The evolution of additive manufacturing, commonly known as 3D printing, has been a remarkable journey that has transformed numerous industries by redefining traditional manufacturing processes, fostering innovation, and enabling unprecedented levels of customization, efficiency, and design flexibility. This technology has grown from a niche concept to a powerful tool with broad applications across diverse sectors, including the thermal engineering field.

In the realm of air-cooled heat exchangers, the integration of additive manufacturing has opened up new avenues for customized and optimized fabrication. Traditionally, the design and production of air-cooled heat exchangers have been constrained by the limitations of conventional manufacturing methods. However, the advent of 3D printing has revolutionized this landscape, empowering engineers and designers to push the boundaries of what is possible.

Customized Air-Cooled Heat Exchanger Design

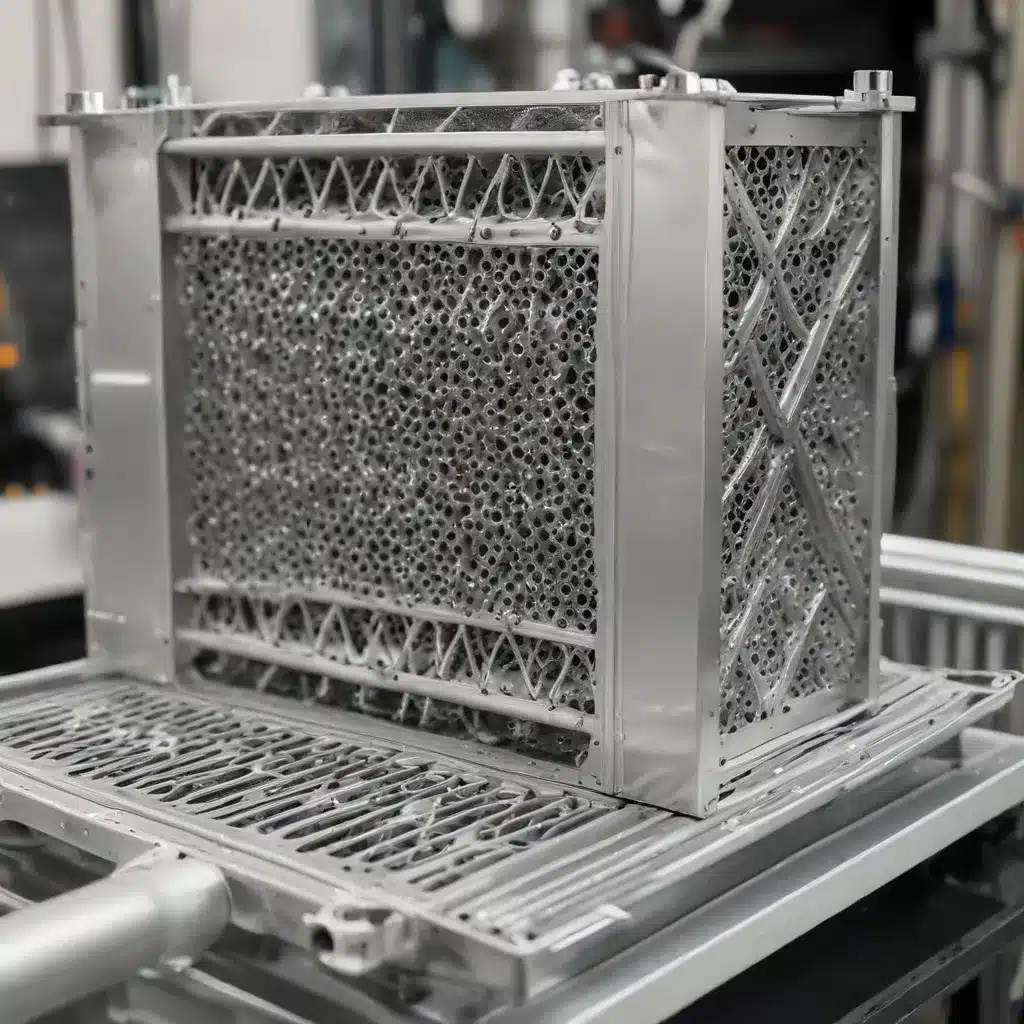

One of the primary advantages of additive manufacturing in the context of air-cooled heat exchangers is the ability to create highly customized designs tailored to specific applications and operating conditions. Traditional manufacturing often relies on standardized geometries and dimensions, limiting the potential for optimization. In contrast, 3D printing allows for the fabrication of intricate, complex heat exchanger configurations that can be precisely engineered to meet the unique thermal requirements of a given system.

By leveraging advanced CAD software and 3D modeling techniques, engineers can now design air-cooled heat exchangers with intricate flow paths, optimized fin structures, and enhanced heat transfer surfaces. These customized designs can account for factors such as the specific heat load, ambient conditions, and space constraints, enabling a higher degree of thermal performance optimization.

Integrating additive manufacturing into the design process of air-cooled heat exchangers also empowers engineers to explore novel geometries and innovative heat transfer enhancement strategies that were previously challenging or cost-prohibitive to implement. This newfound design freedom paves the way for the development of more efficient, compact, and reliable heat exchanger solutions.

Material Advancements and Thermal Performance

The versatility of additive manufacturing extends beyond design flexibility; it also introduces new possibilities in terms of material selection and thermal performance optimization. Conventional manufacturing methods for air-cooled heat exchangers have typically been limited to a narrow range of metallic materials, such as aluminum and copper, due to the constraints of traditional fabrication processes.

However, the advent of additive manufacturing has expanded the material palette, allowing for the utilization of a wider range of materials, including advanced alloys, ceramics, and even composite materials. These novel materials can be tailored to offer enhanced thermal conductivity, corrosion resistance, and durability, all of which are crucial factors in the performance and lifespan of air-cooled heat exchangers.

Furthermore, additive manufacturing techniques, such as selective laser melting (SLM) and electron beam melting (EBM), enable the creation of highly complex internal structures and features within the heat exchanger components. These intricate geometries can be designed to improve airflow, enhance heat transfer, and minimize pressure drop, ultimately leading to significant improvements in thermal efficiency and overall system performance.

Maintenance and Repair Considerations

In addition to the advantages in design and thermal performance, additive manufacturing also holds the potential to revolutionize the maintenance and repair of air-cooled heat exchangers. Traditionally, the replacement or repair of damaged or worn-out heat exchanger components has been a challenging and time-consuming process, often requiring specialized equipment and skilled technicians.

However, the integration of 3D printing into the maintenance ecosystem can streamline these processes. By maintaining a digital library of heat exchanger component designs, repair services can rapidly produce replacement parts on-demand, reducing downtime and minimizing the need for extensive inventory. This capability is particularly beneficial for addressing unique or legacy heat exchanger models, where finding compatible spare parts can be a significant challenge.

Moreover, additive manufacturing techniques enable the fabrication of customized repair solutions, such as tailored fin structures or specialized coatings, to address specific wear or damage patterns. This level of customization can extend the lifespan of air-cooled heat exchangers and optimize their performance over time, ultimately enhancing the overall lifecycle management of these critical thermal systems.

Enabling Rapid Prototyping and Agile Manufacturing

The inherent speed and flexibility of additive manufacturing have also transformed the way air-cooled heat exchanger designs are developed and brought to market. Rapid prototyping enabled by 3D printing allows engineers to quickly iterate on design concepts, test alternative configurations, and validate thermal performance without the lengthy lead times and high costs associated with traditional manufacturing methods.

This agile approach to design and development empowers thermal engineering teams to respond more effectively to evolving market demands, industry regulations, and customer-specific requirements. The ability to swiftly produce physical prototypes and perform on-site testing further enhances the optimization process, leading to more efficient and reliable air-cooled heat exchanger solutions.

Expanding the Frontiers of Air-Cooled Heat Exchanger Applications

The integration of additive manufacturing into the air-cooled heat exchanger domain has also opened up new frontiers of application. Beyond traditional industrial and commercial settings, the customization and design flexibility offered by 3D printing have enabled the development of specialized heat exchanger solutions for niche markets and emerging technologies.

For instance, the aerospace and defense industries have increasingly embraced additive manufacturing for the production of lightweight, high-performance air-cooled heat exchangers that are crucial for the thermal management of avionics, propulsion systems, and other mission-critical components. The ability to fabricate intricate geometries and optimize heat transfer characteristics has been a game-changer in these sectors, where weight and space constraints are of paramount importance.

Similarly, the growing adoption of renewable energy technologies, such as concentrated solar power plants and high-performance electric vehicles, has driven the demand for customized air-cooled heat exchangers that can efficiently manage the thermal loads associated with these applications. Additive manufacturing has empowered engineers to design and rapidly iterate on heat exchanger solutions tailored to the unique requirements of these emerging markets.

Addressing Challenges and Future Outlook

While the integration of additive manufacturing into air-cooled heat exchanger fabrication has presented numerous opportunities, it is not without its challenges. Ensuring consistent material properties, quality control, and compliance with industry standards are crucial considerations that require robust processes and ongoing research and development.

Advancements in material science and printing technologies continue to address these challenges, paving the way for the widespread adoption of additive manufacturing in the thermal engineering field. As the technology matures and becomes more accessible, the potential for customized and optimized air-cooled heat exchanger solutions to revolutionize various industries grows ever stronger.

Looking ahead, the synergy between additive manufacturing and air-cooled heat exchanger design holds immense promise. By empowering engineers to push the boundaries of thermal management, this convergence of technologies will undoubtedly lead to more efficient, reliable, and sustainable thermal systems that can adapt to the evolving needs of modern industries and the ever-changing environmental landscape.