The Transformative Role of Nanotech in Cooling Systems

Nanotechnology has emerged as a pivotal force in revolutionizing cooling technologies, offering unprecedented opportunities to enhance efficiency and performance. By manipulating materials on an atomic scale, nanotechnology optimizes the thermal management capabilities of cooling systems, driving a significant leap forward in this critical field.

Nanofluids, consisting of nanoparticles suspended in a base fluid, exemplify the power of nanotechnology in cooling applications. These advanced fluids exhibit superior thermal conductivity, enabling enhanced heat dissipation and more effective cooling of devices such as computer processors. Nanomuscle.com highlights how the integration of nanofluids into cooling systems can lead to a remarkable reduction in energy consumption, potentially lowering US energy usage by up to 20%.

The versatility of nanotechnology extends beyond nanofluids, with innovations like carbon nanotubes (CNTs) and graphene-based materials playing a transformative role in thermal management. CNTs, with their exceptional thermal conductivity, are now being utilized in micro-electromechanical systems (MEMS) to enable effective heat dissipation. Similarly, the superior heat conduction properties of graphene-based materials have revolutionized the electronics cooling industry, paving the way for more efficient and compact cooling solutions. Nanomuscle.com

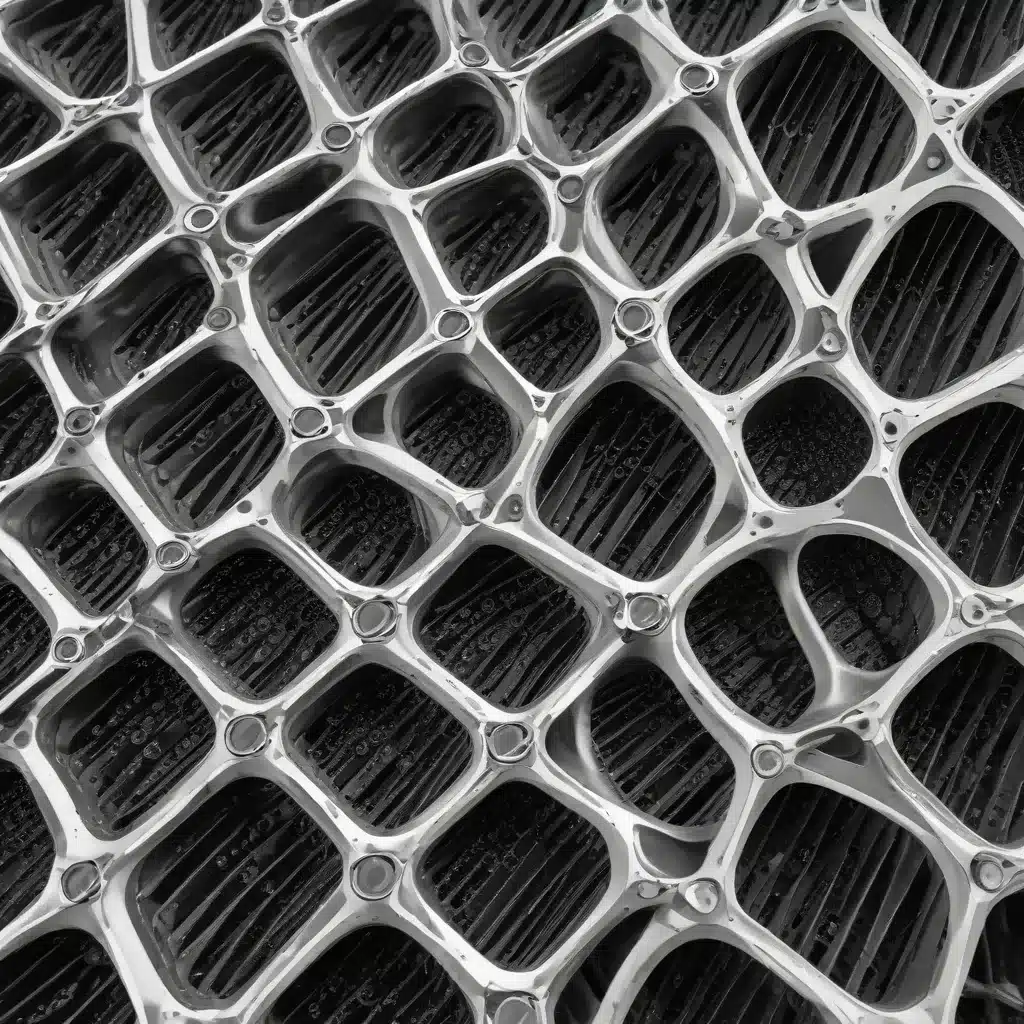

Nanomaterials and advanced coatings have also made significant strides in enhancing the performance of air-cooled heat exchangers, a crucial component in various industrial and commercial applications. By leveraging the unique properties of these innovative materials, air-cooled heat exchangers can achieve greater thermal efficiency, improved heat transfer rates, and enhanced durability, ultimately contributing to the optimization of overall system performance.

Understanding the Thermal Landscape: Factors Influencing Air-Cooled Heat Exchanger Efficiency

The performance of air-cooled heat exchangers is intrinsically tied to their ability to effectively manage thermal energy. A deep understanding of the underlying factors that influence heat exchanger efficiency is crucial for unlocking the full potential of these systems.

One of the primary factors affecting air-cooled heat exchanger performance is the thermal conductivity of the materials used in their construction. Traditionally, metals like aluminum and copper have been the go-to choices due to their high thermal conductivity. However, the emergence of advanced nanomaterials, such as carbon nanotubes and graphene, has opened up new frontiers in heat transfer optimization.

These nanomaterials possess extraordinary thermal properties, enabling them to outperform conventional metallic materials in heat dissipation capabilities. By incorporating nanomaterials into the design of air-cooled heat exchangers, engineers can achieve enhanced thermal conductivity, leading to improved heat transfer rates and higher overall efficiency.

Another critical factor influencing air-cooled heat exchanger performance is the surface characteristics of the heat transfer surfaces. The use of advanced coatings, particularly those incorporating nanomaterials, has demonstrated remarkable potential in enhancing heat transfer efficiency. ScienceDirect.com

Nanocoatings can reduce thermal resistance, minimize fouling and corrosion, and improve heat transfer coefficients, ultimately contributing to enhanced overall performance. These coatings can be tailored to specific applications, ensuring optimal thermal management in diverse industrial settings.

Furthermore, the design and configuration of air-cooled heat exchangers play a significant role in their efficiency. Factors such as the arrangement of tubes, fin geometry, and airflow patterns can all impact the heat transfer capabilities of the system. By leveraging computational fluid dynamics (CFD) simulations and advanced modeling techniques, engineers can optimize the design of air-cooled heat exchangers, maximizing their thermal performance.

Nanomaterials and Advanced Coatings: Enhancing Air-Cooled Heat Exchanger Efficiency

The integration of nanomaterials and advanced coatings has been a game-changer in the realm of air-cooled heat exchanger technology, leading to significant improvements in efficiency and overall system performance.

Nanomaterials: Pushing the Boundaries of Thermal Management

Nanomaterials, with their exceptional thermal properties, have emerged as a transformative solution for air-cooled heat exchangers. Carbon nanotubes (CNTs) and graphene-based materials, in particular, have demonstrated remarkable potential in enhancing heat transfer capabilities.

The high thermal conductivity of CNTs allows for efficient heat dissipation, making them an ideal choice for integration into air-cooled heat exchanger designs. By incorporating CNTs into the heat transfer surfaces or fins, engineers can effectively improve the overall heat transfer rate of the system, resulting in enhanced cooling performance.

Graphene-based materials, known for their superior thermal conductivity, have also found their way into air-cooled heat exchanger applications. These advanced materials can be used to create highly efficient thermal interface coatings or as integrated components within the heat exchanger structure, enabling uniform heat distribution and minimizing localized hot spots.

The use of nanofluids, containing nanoparticles suspended in a base fluid, has also proven to be a game-changing innovation in air-cooled heat exchanger technology. These nanofluids exhibit enhanced thermal conductivity, allowing for more effective heat transfer between the air and the heat exchanger surfaces. SustainEnergyRes.SpringerOpen.com

Advanced Coatings: Optimizing Surface Characteristics

In addition to the advancements in nanomaterials, the development of advanced coatings has significantly contributed to the enhanced efficiency of air-cooled heat exchangers. These coatings can be tailored to address specific challenges, such as fouling, corrosion, and thermal resistance.

Nanocoatings, in particular, have demonstrated exceptional performance in improving heat transfer coefficients and reducing thermal resistance. By applying these coatings to the heat transfer surfaces, engineers can create a smoother, more uniform surface, facilitating better airflow and more efficient heat dissipation.

Furthermore, nanocoatings can enhance the wettability and anti-fouling properties of heat exchanger surfaces, preventing the accumulation of contaminants and maintaining optimal heat transfer characteristics over extended periods of operation. ScienceDirect.com

The combination of nanomaterials and advanced coatings has led to the creation of highly efficient and reliable air-cooled heat exchangers, capable of withstanding diverse operating conditions and delivering exceptional thermal performance.

Real-World Applications and Case Studies

The transformative impact of nanomaterials and advanced coatings on air-cooled heat exchanger performance has been demonstrated in various real-world applications across diverse industries.

Power Generation and Industrial Cooling

In the power generation industry, air-cooled heat exchangers equipped with nanocoatings have shown remarkable resilience to extreme operating conditions. Power plants, for example, have integrated these coatings to maintain optimal performance under high-temperature and high-pressure environments, ensuring reliable and efficient cooling of critical components.

Nanomuscle.com highlights the success stories of data centers that have implemented nanofluid-based cooling solutions to address the challenge of high heat loads. By replacing traditional coolants with nanofluids, these facilities have achieved improved temperature control and reduced energy consumption, enhancing the overall sustainability of their operations.

Automotive and HVAC Applications

The automotive industry has also reaped the benefits of nanomaterials and advanced coatings in air-cooled heat exchanger applications. The integration of these technologies has led to the development of more compact and efficient cooling systems for vehicles, contributing to improved fuel efficiency and reduced emissions.

In the HVAC (Heating, Ventilation, and Air Conditioning) sector, air-cooled heat exchangers with nanocoatings have demonstrated enhanced performance in personal cooling devices like air conditioners and wearable coolers. These coatings have been found to reduce energy consumption and improve thermal regulation, enhancing comfort and efficiency for end-users.

Aerospace and Electronics Cooling

The aerospace industry has also embraced the benefits of nanomaterials and advanced coatings in air-cooled heat exchanger applications. The unique thermal management requirements of aircraft and spacecraft have driven the adoption of these innovative solutions, ensuring reliable and efficient cooling of critical electronic components and systems.

In the electronics cooling domain, the incorporation of graphene-based materials and carbon nanotubes into air-cooled heat exchanger designs has revolutionized the industry. These advanced materials have enabled more effective heat dissipation, addressing the challenges posed by the ever-increasing power densities of modern electronic devices.

The Future of Air-Cooled Heat Exchangers: Unlocking the Potential of Nanomaterials and Advanced Coatings

As the world continues to seek more efficient and sustainable cooling solutions, the future of air-cooled heat exchanger technology holds immense promise, driven by the remarkable advancements in nanomaterials and advanced coatings.

Ongoing research and development in this field are focused on further enhancing the thermal performance, durability, and cost-effectiveness of air-cooled heat exchangers. Emerging nanomaterials, such as two-dimensional materials and nanocomposites, are being explored to push the boundaries of thermal conductivity and heat transfer capabilities.

Moreover, the integration of smart and adaptive technologies, such as real-time monitoring systems and dynamic control algorithms, is set to revolutionize the way air-cooled heat exchangers are managed and optimized. These innovations will enable predictive maintenance, proactive adjustments, and enhanced system resilience, ultimately leading to improved overall efficiency and reliability.

The quest for sustainable cooling solutions is also driving the exploration of hybrid and integrated cooling systems, where air-cooled heat exchangers are combined with other technologies, such as thermoelectric modules or phase-change materials. These hybrid approaches have the potential to unlock new levels of thermal management, catering to the diverse needs of various industries.

As the industry continues to evolve, the role of nanomaterials and advanced coatings in air-cooled heat exchanger technology will only become more prominent. By leveraging these innovative solutions, engineers and researchers can unlock unprecedented levels of efficiency, reliability, and environmental sustainability, paving the way for a future where cooling systems operate at the pinnacle of performance and energy-efficiency.

At Air Cooled Heat Exchangers, we are committed to staying at the forefront of these advancements, providing our readers with the latest insights, practical tips, and industry-leading expertise to help them navigate the ever-evolving landscape of air-cooled heat exchanger technology.