Unlocking the Potential of Nanofluids for Enhanced Heat Transfer

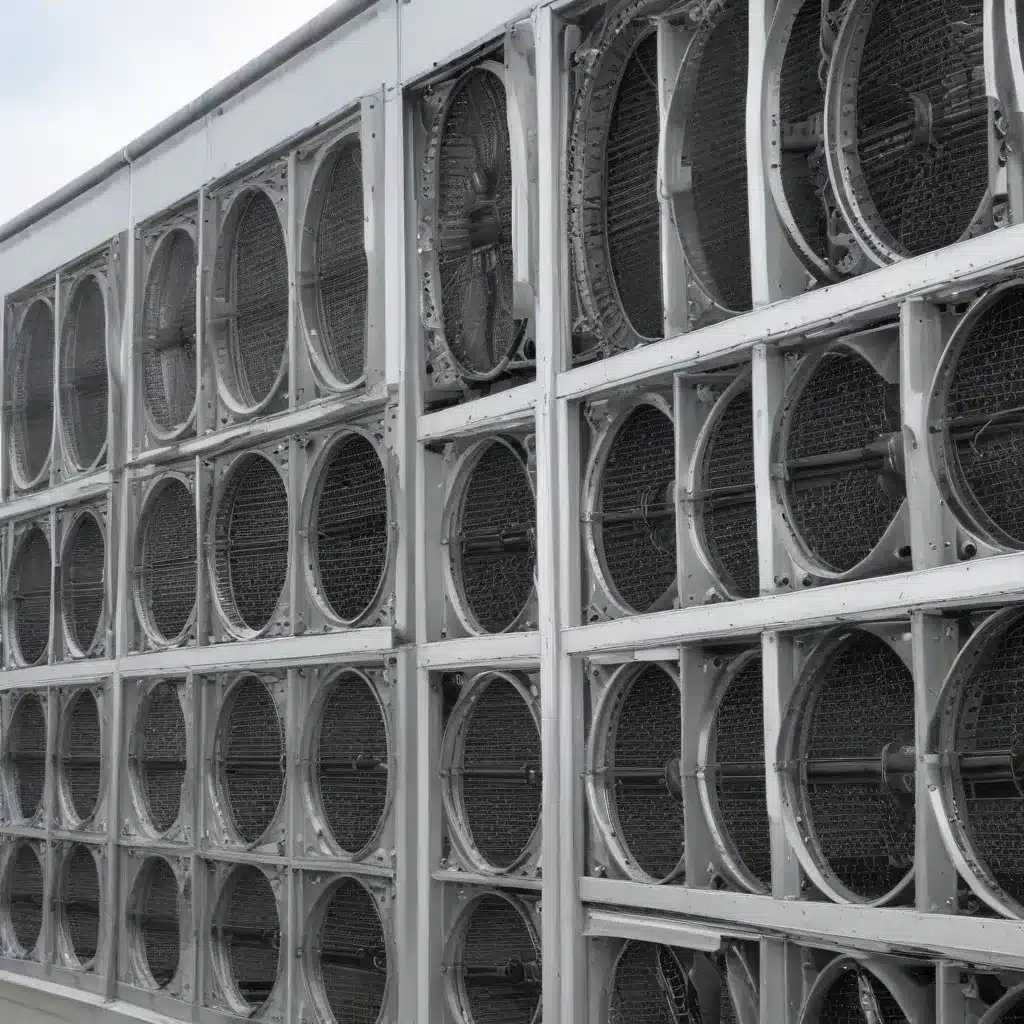

In the ever-evolving landscape of modern engineering, the demand for efficient and sustainable cooling solutions has become paramount. Air-cooled heat exchangers, renowned for their versatility and widespread application, have emerged as a critical component in various industries, from power generation to manufacturing. As global energy needs continue to surge, the imperative to enhance the thermal performance of these heat exchangers has gained renewed momentum.

Enter the realm of nanofluids – a revolutionary class of engineered fluids that hold the promise of revolutionizing the world of heat transfer. By dispersing microscopic nanoparticles within a base fluid, such as water or glycol, nanofluids exhibit enhanced thermal conductivity, superior heat transfer coefficients, and improved overall thermal performance. This extraordinary capability has positioned nanofluids as a game-changing solution for air-cooled heat exchangers, unlocking new frontiers in efficiency and sustainability.

In this comprehensive article, we will delve deep into the intricacies of harnessing nanofluids to optimize the performance of air-cooled heat exchangers. From understanding the underlying principles to exploring practical applications across various industries, we will equip you with the knowledge and insights to navigate the ever-evolving landscape of this cutting-edge technology.

The Science of Nanofluids: Enhancing Thermal Transport Properties

At the heart of the nanofluid revolution lies a fundamental understanding of the unique properties that emerge when nano-scale particles are dispersed within a base fluid. These nanoparticles, often made of materials such as metals, oxides, or carbon-based compounds, possess extraordinary thermal conductivity that far outpaces their bulk counterparts.

When incorporated into a base fluid, the nanoparticles interact with the surrounding molecules, creating a synergistic effect that amplifies the overall thermal transport capabilities. This phenomenon is attributed to the increased surface area-to-volume ratio of the nanoparticles, which facilitates more efficient heat transfer through mechanisms such as Brownian motion, thermophoresis, and enhanced thermal dispersion.

Notably, the choice of nanoparticle material and its concentration within the base fluid play a crucial role in determining the thermal performance of the resulting nanofluid. Materials like silver, copper, and aluminum oxide have garnered significant attention due to their exceptional thermal conductivity, while the optimal nanoparticle concentration is a delicate balance between enhanced heat transfer and maintaining fluid stability.

Harnessing Nanofluids for Air-Cooled Heat Exchanger Applications

The integration of nanofluids into air-cooled heat exchangers has opened up a world of possibilities for improving thermal efficiency and optimizing energy usage. By leveraging the enhanced heat transfer properties of nanofluids, air-cooled heat exchangers can achieve higher heat dissipation rates, leading to reduced footprint, improved system compactness, and enhanced overall performance.

One of the key advantages of using nanofluids in air-cooled heat exchangers is their ability to enhance the convective heat transfer coefficient. The increased thermal conductivity and thermal diffusivity of nanofluids enable more efficient heat transfer from the heat exchanger surfaces to the working fluid, resulting in higher heat dissipation rates.

Furthermore, the unique flow characteristics of nanofluids, such as reduced boundary layer thickness and increased fluid mixing, contribute to the improved heat transfer performance. This can lead to a reduction in the required heat exchanger size, ultimately resulting in cost savings and improved system integration.

Optimizing Air-Cooled Heat Exchanger Design with Nanofluids

Designing air-cooled heat exchangers that effectively leverage the benefits of nanofluids requires a comprehensive understanding of the complex interplay between fluid dynamics, heat transfer, and material properties. Careful consideration of factors such as nanoparticle type, concentration, and flow conditions is essential to achieve optimal thermal performance.

One innovative approach in this context involves the strategic placement of rotating cylinders within the heat exchanger’s flow channels. These rotating elements can induce turbulence and enhance fluid mixing, further amplifying the heat transfer capabilities of the nanofluid. By adjusting parameters like the cylinder’s rotational speed and the volume fraction of nanoparticles, engineers can fine-tune the heat exchanger’s efficiency and tailor it to specific application requirements.

Additionally, the integration of advanced simulation and modeling techniques, such as computational fluid dynamics (CFD), has enabled designers to accurately predict the behavior of nanofluids within air-cooled heat exchangers. These powerful tools allow for the optimization of design parameters, including channel geometry, airflow patterns, and nanoparticle distribution, ensuring that the full potential of nanofluids is harnessed for enhanced thermal performance.

Maintenance and Operational Considerations for Nanofluid-based Air-Cooled Heat Exchangers

While the advantages of using nanofluids in air-cooled heat exchangers are compelling, it is crucial to address the operational and maintenance challenges that may arise. Proper handling and maintenance protocols are essential to ensure the long-term reliability and performance of these systems.

One key consideration is the potential for nanoparticle agglomeration and sedimentation within the heat exchanger’s fluid circuits. Over time, inadequate dispersion or changes in operating conditions can lead to the accumulation of nanoparticles, potentially clogging passages and reducing heat transfer efficiency. Proactive maintenance strategies, such as regular fluid monitoring, filtration, and the incorporation of stabilizing additives, can mitigate these concerns and maintain the integrity of the nanofluid-based system.

Furthermore, the compatibility of nanofluid components with the heat exchanger’s materials and seals must be carefully evaluated. Potential corrosion, erosion, or material degradation issues need to be addressed through the selection of appropriate construction materials and the implementation of comprehensive preventive maintenance protocols.

Industry Applications and Case Studies: Unlocking the Potential of Nanofluid-based Air-Cooled Heat Exchangers

The versatility of nanofluid-based air-cooled heat exchangers has led to their adoption across a diverse range of industries, each with its unique set of thermal management challenges and performance requirements. From power generation and manufacturing to HVAC systems and data centers, these innovative heat exchangers are revolutionizing the way we approach thermal management.

In the power generation sector, nanofluid-based air-cooled heat exchangers have demonstrated their ability to enhance the efficiency of steam turbine condensers, reducing the overall footprint and water consumption of these critical components. Case studies have shown that the implementation of nanofluids can lead to significant improvements in heat transfer rates, enabling more compact and energy-efficient power plant designs.

Similarly, in the manufacturing industry, nanofluid-based air-cooled heat exchangers have found applications in the cooling of high-performance machine tools, electronic equipment, and industrial processes. By effectively dissipating heat and maintaining optimal operating temperatures, these heat exchangers contribute to increased productivity, process reliability, and energy savings.

The advantages of nanofluid-based air-cooled heat exchangers are also evident in the HVAC industry, where they are being utilized to improve the efficiency and compact design of commercial and residential cooling systems. The enhanced heat transfer capabilities of nanofluids enable more effective cooling, reduced energy consumption, and improved system reliability, making them a compelling solution for modern building environments.

Conclusion: Embracing the Future of Nanofluid-Powered Air-Cooled Heat Exchangers

In the ever-evolving landscape of thermal management and energy efficiency, the integration of nanofluids into air-cooled heat exchangers has emerged as a transformative force. By harnessing the exceptional thermal properties of these engineered fluids, engineers and designers can push the boundaries of heat transfer performance, creating more compact, efficient, and sustainable cooling solutions.

As we continue to explore the vast potential of nanofluid-based air-cooled heat exchangers, the future holds endless possibilities. Advancements in materials science, fluid dynamics, and computational modeling will undoubtedly lead to further enhancements in thermal management capabilities, paving the way for innovative applications across diverse industries.

By embracing this cutting-edge technology, organizations can stay ahead of the curve, optimizing their energy usage, reducing carbon footprints, and delivering superior thermal management solutions that meet the ever-increasing demands of the modern world. The journey towards a more energy-efficient future starts with the exploration of nanofluids and their transformative impact on air-cooled heat exchangers.

Discover the power of nanofluids and unlock a new era of thermal performance with Air Cooled Heat Exchangers, your trusted partner in pioneering sustainable cooling solutions.