Unlocking the Potential of Nanofluids for Enhanced Air-Cooled Heat Exchanger Efficiency

As a seasoned expert in the realm of air-cooled heat exchangers, I’ve witnessed the industry’s relentless pursuit of innovative solutions to improve efficiency and performance. One such promising approach that has captured the attention of thermal engineers and researchers is the integration of nanofluids into air-cooled heat exchanger systems.

Nanofluids, a cutting-edge class of engineered fluids, have emerged as a transformative tool in the quest to enhance heat transfer capabilities. Comprised of base fluids, such as water or glycol, infused with minute metallic or metallic oxide nanoparticles, nanofluids possess remarkable thermal properties that surpass those of their conventional counterparts.

In this comprehensive article, we’ll delve into the intricate workings of air-cooled heat exchangers and uncover the profound impact that nanofluids can have on their performance. We’ll explore the underlying principles, practical applications, and optimization strategies that can unlock the true potential of these advanced cooling solutions.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

Air-cooled heat exchangers are a ubiquitous and versatile subset of heat transfer equipment, found across a wide range of industries, from power generation and HVAC systems to chemical processing and industrial manufacturing. These ingenious devices harness the power of forced or natural convection, using air as the primary cooling medium to dissipate heat from a variety of heat-generating sources.

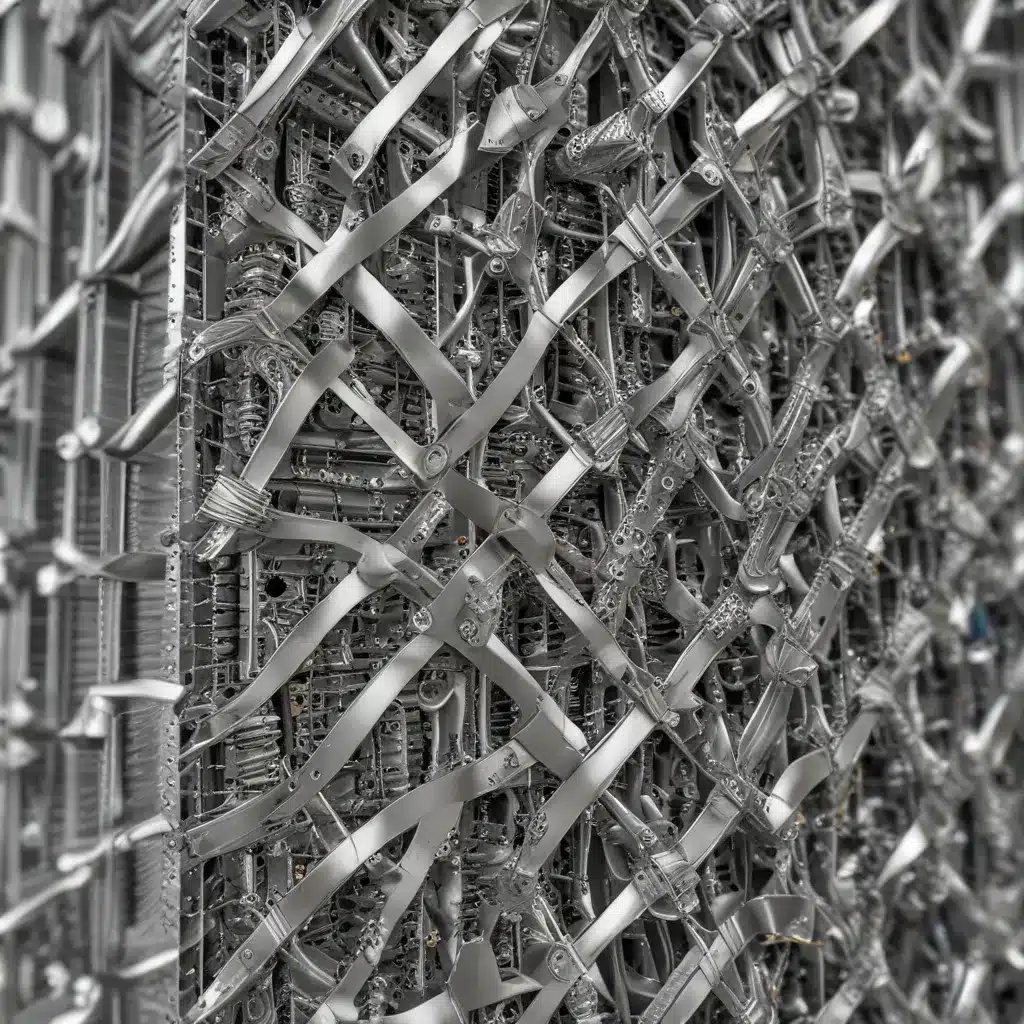

The core design of an air-cooled heat exchanger typically consists of a network of finned tubes or plate-fin assemblies, strategically arranged to maximize the surface area exposed to the airflow. As the air passes over these heat transfer surfaces, it absorbs the thermal energy, effectively cooling the fluid or material within the exchanger.

One of the primary challenges facing air-cooled heat exchangers, however, is the inherently low thermal conductivity of air. This physical limitation can result in suboptimal heat transfer rates, leading to reduced overall system efficiency and potential performance bottlenecks. This is where the introduction of nanofluids into the heat exchanger design can yield transformative results.

Nanofluids: Revolutionizing Air-Cooled Heat Transfer

Nanofluids, as mentioned earlier, are engineered fluids that incorporate nanoparticles, typically made of metals or metal oxides, dispersed within a base fluid. These nanoparticles, measuring only a few nanometers in size, possess exceptional thermal properties that can significantly enhance the heat transfer capabilities of the base fluid.

The addition of these nanoparticles to the base fluid, such as water or glycol, alters the fluid’s thermal conductivity, viscosity, and heat capacity in a manner that dramatically improves its heat transfer performance. This enhanced heat transfer can be attributed to several factors, including the increased thermal conductivity of the nanofluid, the Brownian motion of the nanoparticles, and the increased surface area-to-volume ratio of the nanoparticles.

When integrated into an air-cooled heat exchanger, nanofluids can act as a potent heat transfer medium, effectively absorbing and dissipating thermal energy at a much higher rate than traditional cooling fluids. This improved heat transfer efficiency can lead to several tangible benefits, including:

-

Increased Cooling Capacity: Nanofluids’ superior thermal properties allow air-cooled heat exchangers to dissipate more heat, enabling higher heat loads to be managed without compromising performance.

-

Reduced Equipment Size: The enhanced heat transfer capabilities of nanofluids can potentially allow for the use of smaller air-cooled heat exchanger units, leading to space and cost savings.

-

Improved Energy Efficiency: By enhancing the heat transfer process, nanofluids can contribute to reduced energy consumption and operational costs associated with air-cooled heat exchanger systems.

-

Enhanced Reliability: Improved heat transfer can help maintain optimal operating temperatures for critical components, promoting system reliability and extending equipment lifespan.

Optimizing Air-Cooled Heat Exchanger Performance with Nanofluids

Harnessing the full potential of nanofluids in air-cooled heat exchanger applications requires a comprehensive understanding of the various parameters that influence their performance. Let’s explore some of the key factors to consider:

Nanoparticle Selection and Concentration

The choice of nanoparticle type and its concentration within the base fluid can have a significant impact on the heat transfer characteristics of the nanofluid. Factors such as the nanoparticle material, size, and volume fraction can all contribute to the overall thermal performance.

Research has shown that nanoparticles with higher thermal conductivity, such as silver or copper, tend to outperform materials like titanium oxide in terms of enhancing heat transfer. However, the optimal nanoparticle concentration must be carefully balanced, as excessive concentrations can lead to increased viscosity and pressure drop within the heat exchanger, potentially offsetting the benefits.

Fluid Flow and Fluid Dynamics

The way the nanofluid flows through the air-cooled heat exchanger plays a crucial role in its heat transfer efficiency. Factors like the Reynolds number, which describes the ratio of inertial to viscous forces, and the flow regime (laminar or turbulent) can significantly influence the heat transfer performance.

Strategies such as incorporating turbulence-inducing elements, like rotating cylinders or baffles, within the heat exchanger’s flow path can further enhance the convective heat transfer by promoting fluid mixing and boundary layer disruption.

Thermal Management and Optimization

Effectively managing the thermal performance of air-cooled heat exchangers involves optimizing a range of parameters, including:

- Airflow rate and direction

- Fin design and geometry

- Nanofluid flow rate and operating temperature

- Integration of advanced heat transfer enhancement techniques

By carefully adjusting these variables, heat exchanger designers can unlock the full potential of nanofluids, ensuring optimal heat dissipation, reduced thermal stresses, and improved overall system efficiency.

Practical Applications and Case Studies

The application of nanofluids in air-cooled heat exchanger systems extends across a diverse range of industries, each with its unique challenges and requirements. Let’s explore a few illustrative examples:

Power Generation and HVAC

In power generation facilities, air-cooled heat exchangers play a critical role in cooling power-generating equipment, such as turbines and generators. The integration of nanofluids in these systems can lead to enhanced heat dissipation, allowing for increased power output and improved overall plant efficiency.

Similarly, in HVAC applications, air-cooled heat exchangers are commonly used for cooling and heat rejection. Nanofluids can enhance the performance of these systems, leading to more efficient climate control, reduced energy consumption, and improved comfort for building occupants.

Chemical and Process Industries

Air-cooled heat exchangers are extensively utilized in chemical processing plants, where they are tasked with cooling a wide range of heat-generating equipment and processes. The use of nanofluids in these applications can result in more effective heat transfer, better temperature control, and enhanced process safety and reliability.

Automotive and Transportation

In the automotive and transportation sectors, air-cooled heat exchangers are employed for cooling critical components, such as engine coolant, transmission fluid, and electronics. The integration of nanofluids in these systems can lead to improved cooling efficiency, reduced weight, and enhanced overall vehicle performance and fuel economy.

Maintenance and Optimization Strategies

Maintaining the optimal performance of air-cooled heat exchangers equipped with nanofluids requires a proactive and well-informed approach. Key maintenance and optimization strategies include:

-

Periodic Nanofluid Analysis: Regular monitoring and analysis of the nanofluid’s composition, stability, and thermal properties can help identify any degradation or contamination, allowing for timely maintenance and replenishment.

-

Fouling and Scaling Prevention: Implementing effective cleaning protocols and monitoring for potential fouling or scaling can help maintain the heat transfer surfaces’ efficiency and minimize pressure drop.

-

Airflow Optimization: Regularly inspecting and maintaining the airflow pathways, fan operation, and heat exchanger geometry can ensure optimal heat dissipation and mitigate performance degradation over time.

-

Thermal Performance Monitoring: Continuous monitoring of key parameters, such as inlet and outlet temperatures, pressure drops, and overall heat transfer coefficients, can provide valuable insights for optimization and troubleshooting.

-

Predictive Maintenance: Adopting advanced predictive maintenance strategies, leveraging data analytics and machine learning, can help anticipate potential failures and enable proactive maintenance, maximizing the air-cooled heat exchanger’s operational lifespan.

By diligently implementing these maintenance and optimization strategies, air-cooled heat exchanger operators can ensure the long-term performance, reliability, and efficiency of their systems, while fully capitalizing on the benefits of nanofluid-based cooling.

Conclusion: Embracing the Future of Air-Cooled Heat Exchangers

As the global demand for energy continues to rise, the importance of harnessing efficient and sustainable thermal management solutions has never been more paramount. The integration of nanofluids into air-cooled heat exchanger systems represents a transformative step forward, offering the potential to unlock unprecedented levels of heat transfer performance and energy efficiency.

By understanding the fundamental principles, optimizing key parameters, and implementing robust maintenance practices, thermal engineers and industry professionals can harness the power of nanofluids to revolutionize the way we cool critical equipment and processes. As we continue to push the boundaries of thermal management technology, the future of air-cooled heat exchangers looks brighter than ever, poised to deliver reliable, efficient, and sustainable cooling solutions for a wide range of applications.

To learn more about the latest advancements in air-cooled heat exchanger technology and the role of nanofluids, I encourage you to visit the Air Cooled Heat Exchangers blog, where you’ll find a wealth of valuable resources and expert insights.