The Evolving Landscape of Electronic Cooling Challenges

The rapid advancements in the electronics industry have led to a significant increase in power densities and heat generation within electronic devices. As these devices become smaller, smarter, and more powerful, the need for effective thermal management has become more critical than ever before. Conventional cooling techniques, such as natural and forced air convection, are often insufficient to dissipate the high heat fluxes generated by modern electronics.

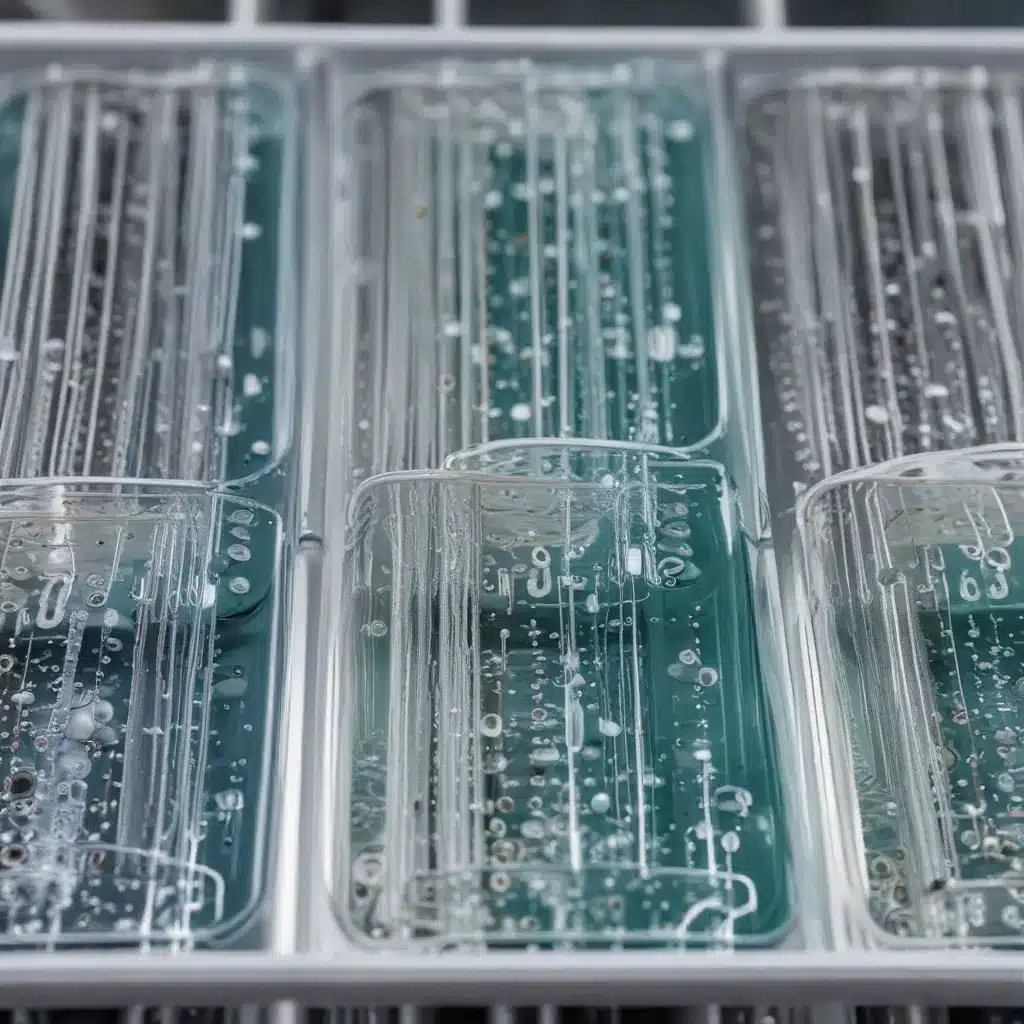

Addressing these challenges requires innovative approaches that can effectively manage the thermal performance of electronic systems. One such promising solution is the integration of microfluidics technology into air-cooled heat exchangers. Microfluidics, with its ability to precisely control the flow and behavior of fluids at the microscale, offers unique opportunities to enhance the heat transfer capabilities of air-cooled heat exchangers.

Harnessing the Power of Microfluidics for Thermal Management

Microfluidics technology involves the manipulation and control of fluids at the microscale, often within channels or structures with dimensions ranging from micrometers to millimeters. This precise control over fluid dynamics can be leveraged to optimize the thermal performance of air-cooled heat exchangers in several ways:

-

Enhanced Heat Transfer Coefficients: Microfluidic channels can be designed to create turbulent or chaotic fluid flow, increasing the heat transfer coefficients between the cooling fluid and the heat exchanger surfaces. This leads to more efficient heat dissipation and lower operating temperatures for the electronic components.

-

Targeted Cooling: Microfluidic systems can be tailored to direct the cooling fluid to specific hotspots or high-heat-generating regions within the electronic device. This targeted cooling approach allows for more effective heat management and prevents the formation of hot spots.

-

Integrated Thermal Sensing and Control: Microfluidic systems can be integrated with thermal sensors and control mechanisms to enable real-time monitoring and active regulation of the cooling system. This allows for dynamic adjustments to the cooling parameters, ensuring optimal thermal performance under varying load conditions.

-

Miniaturization and Compact Design: The small scale of microfluidic channels enables the development of compact and lightweight heat exchanger designs, which is particularly important for applications with limited space, such as in portable electronics or aerospace systems.

-

Versatility and Customization: Microfluidic cooling systems can be designed to accommodate a wide range of heat loads, fluid properties, and geometric constraints, making them highly versatile and customizable for various electronic cooling applications.

Microfluidic-Enhanced Air-Cooled Heat Exchangers: Leveraging the Benefits

The integration of microfluidics into air-cooled heat exchangers has the potential to revolutionize thermal management in the electronics industry. By harnessing the unique capabilities of microfluidics, engineers can develop innovative heat exchanger designs that address the growing thermal challenges faced by modern electronic devices.

One of the key advantages of microfluidic-enhanced air-cooled heat exchangers is their ability to achieve higher heat transfer rates compared to traditional air-cooled systems. The micro-scale channels and complex flow patterns generated by microfluidic structures can significantly improve the convective heat transfer coefficients, leading to more efficient heat dissipation.

Furthermore, the targeted cooling capabilities of microfluidic systems can be particularly beneficial for handling hot spots and uneven heat generation within electronic devices. By directing the cooling fluid to specific high-heat regions, the overall thermal performance and reliability of the system can be enhanced.

The integration of thermal sensing and control mechanisms within the microfluidic cooling system also enables dynamic thermal management. This allows the heat exchanger to adapt to changing load conditions, ensuring that the electronic components are kept within their safe operating temperature ranges, even during peak performance or transient events.

Designing Effective Microfluidic-Enhanced Air-Cooled Heat Exchangers

The successful implementation of microfluidic-enhanced air-cooled heat exchangers requires a comprehensive understanding of the underlying principles of microfluidics, heat transfer, and fluid dynamics. Engineers and thermal management specialists must consider several key factors when designing these advanced cooling systems:

-

Microfluidic Channel Geometry: The shape, size, and arrangement of the microfluidic channels play a crucial role in determining the fluid flow and heat transfer characteristics. Optimizing the channel geometry can enhance turbulence, improve heat transfer coefficients, and minimize pressure drops.

-

Fluid Selection and Properties: The choice of the cooling fluid, such as water, refrigerants, or nanofluids, can significantly impact the heat transfer performance. Factors like thermal conductivity, viscosity, and phase change properties must be carefully evaluated.

-

Integrated Thermal Sensing and Control: Incorporating temperature sensors, flow meters, and control algorithms within the microfluidic system enables real-time monitoring and dynamic adjustment of the cooling parameters to maintain optimal thermal performance.

-

Structural Integrity and Reliability: The microfluidic channels must be designed to withstand the operating pressures and temperatures, as well as any mechanical stresses or vibrations, to ensure long-term reliability and durability of the cooling system.

-

Scalability and Manufacturing Considerations: Developing cost-effective and scalable manufacturing processes for microfluidic-enhanced heat exchangers is crucial for their widespread adoption in the electronics industry.

Emerging Trends and Future Prospects

As the electronics industry continues to push the boundaries of performance and miniaturization, the integration of microfluidics in air-cooled heat exchangers is expected to become increasingly prevalent. Some of the emerging trends and future developments in this field include:

-

Advanced Thermal Interface Materials: The use of novel thermal interface materials, such as graphene-based composites or phase change materials, can further enhance the heat transfer between the electronic components and the microfluidic cooling system.

-

Hybrid Cooling Approaches: Combining microfluidic cooling with other thermal management techniques, such as thermoelectric coolers or heat pipes, can create synergistic effects and provide even more effective cooling solutions.

-

Artificial Intelligence and Machine Learning: Integrating AI and ML algorithms into microfluidic cooling systems can enable intelligent, self-optimizing thermal management, adapting to changing operating conditions and maximizing the overall system efficiency.

-

Additive Manufacturing and Microfabrication: Advancements in additive manufacturing and microfabrication techniques can streamline the production of complex microfluidic heat exchanger geometries, leading to more cost-effective and customizable cooling solutions.

-

Sustainable and Energy-Efficient Cooling: Microfluidic-enhanced air-cooled heat exchangers can contribute to the development of more sustainable and energy-efficient cooling systems, aligning with the growing demand for environmentally conscious technologies.

Conclusion

As the electronics industry continues to evolve, the thermal management challenges posed by high-performance and miniaturized devices become increasingly complex. The integration of microfluidics technology into air-cooled heat exchangers offers a promising solution to address these challenges, leveraging the unique capabilities of micro-scale fluid control to enhance heat transfer and enable more effective thermal management.

By harnessing the power of microfluidics, engineers can develop innovative air-cooled heat exchangers that can dissipate high heat fluxes, manage hot spots, and adapt to changing operating conditions. As the field of microfluidic-enhanced thermal management continues to advance, we can expect to see a new generation of air-cooled heat exchangers that push the boundaries of performance, efficiency, and reliability in the electronics industry.