As air-cooled heat exchangers continue to play a crucial role across various industries, the pursuit of enhanced thermal-hydraulic performance has become increasingly important. One promising avenue for optimization lies in the emerging field of microfluidics and the exploration of two-phase flow phenomena. In this comprehensive article, we will delve into the intricate relationship between these engineering frontiers and their transformative potential for air-cooled heat exchanger design, operation, and maintenance.

The Rise of Microfluidics in Heat Transfer Applications

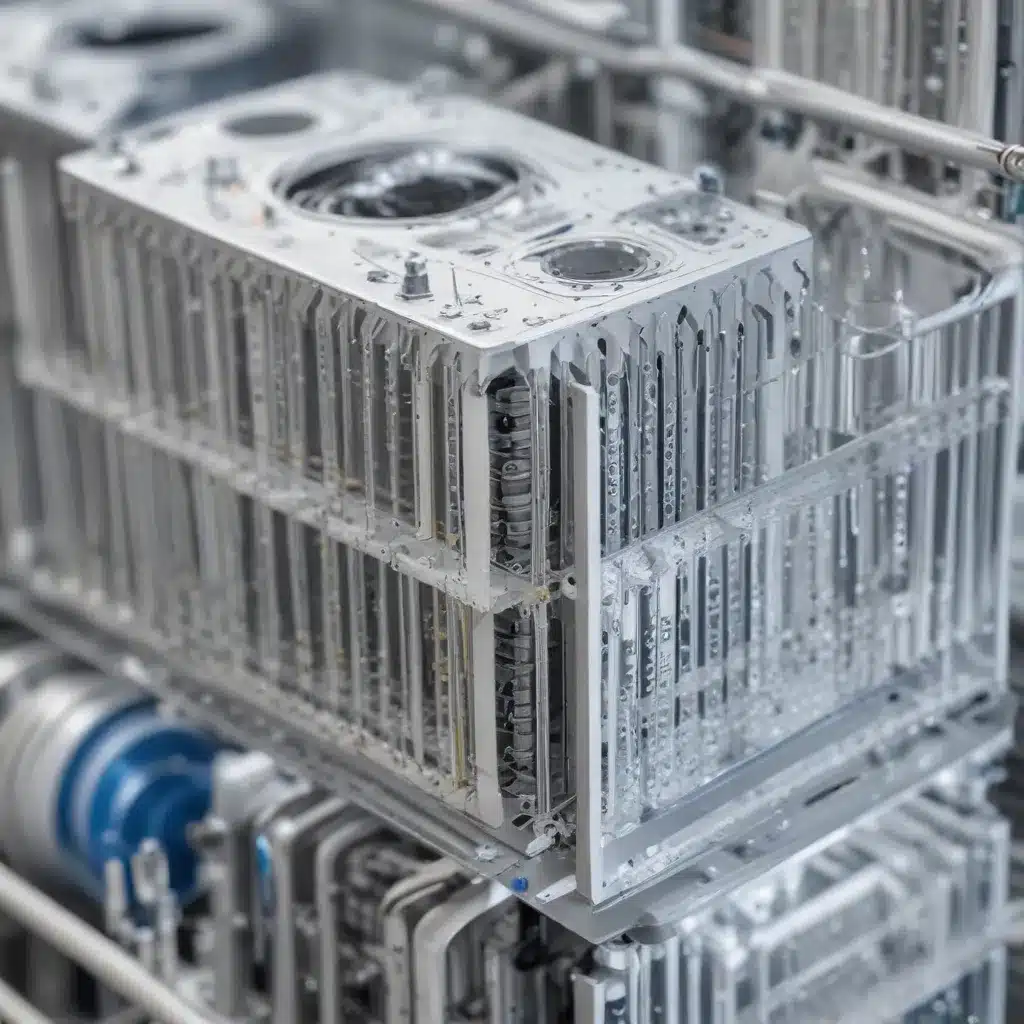

The advancements in miniaturization and the drive for compact, high-performance thermal management systems have propelled the field of microfluidics to the forefront of heat exchanger technology. Microfluidic devices, characterized by their microscale dimensions, offer several inherent advantages that can significantly impact the performance of air-cooled heat exchangers.

One of the primary benefits of microfluidics is the increased surface-to-volume ratio within the heat exchanger channels. This heightened ratio translates to enhanced heat transfer coefficients, as the fluid-surface interactions are intensified at the microscale. Additionally, the small channel dimensions enable higher heat flux removal capabilities, making microfluidic heat exchangers well-suited for applications with stringent space and weight constraints.

Furthermore, the unique flow characteristics observed in microfluidic systems, such as laminar flow, capillary effects, and the dominance of surface forces, can be leveraged to optimize heat transfer processes. For instance, the precise control of fluid flow enabled by microfluidics can lead to improved heat exchanger efficiency and better thermal management of critical components.

Exploring the Potential of Two-Phase Flow

Alongside the advancements in microfluidics, the exploration of two-phase flow phenomena has emerged as a promising approach for enhancing the thermal-hydraulic performance of air-cooled heat exchangers. The phase change processes involved in two-phase flow, such as boiling and condensation, can significantly enhance the heat transfer capabilities of these systems.

One of the key advantages of two-phase flow in air-cooled heat exchangers is the ability to harness the latent heat of vaporization. During the phase change from liquid to vapor, a substantial amount of thermal energy is absorbed, enabling higher heat transfer rates compared to single-phase convective heat transfer alone. This phenomenon can be particularly beneficial in applications where high heat fluxes need to be dissipated, such as in the cooling of power electronics or high-performance computing systems.

Moreover, two-phase flow can improve the overall thermal efficiency of air-cooled heat exchangers by reducing the required airflow rates or heat exchanger size. The enhanced heat transfer coefficients associated with two-phase flow can lead to more compact and energy-efficient heat exchanger designs, making them attractive for a wide range of industrial and commercial applications.

Integrating Microfluidics and Two-Phase Flow

The synergistic integration of microfluidics and two-phase flow holds immense potential for revolutionizing the design, optimization, and performance of air-cooled heat exchangers. By leveraging the unique characteristics of both fields, engineers can unlock novel strategies for thermal management and system-level efficiency improvements.

One promising approach is the development of microchannel heat exchangers that incorporate two-phase flow phenomena. These miniaturized heat exchangers can exploit the benefits of both microfluidics and two-phase flow, such as increased heat transfer coefficients, reduced fluid inventory, and enhanced thermal-hydraulic performance.

| Microfluidic Approach | Two-Phase Flow Approach | Integrated Approach |

|---|---|---|

|

– Increased surface-to-volume ratio – Improved heat flux removal – Precise flow control |

– Harnessing latent heat of vaporization – Enhanced heat transfer coefficients – Improved thermal efficiency |

– Microchannel heat exchangers – Optimized heat transfer performance – Reduced fluid inventory and size |

By strategically combining the advantages of microfluidics and two-phase flow, engineers can develop innovative air-cooled heat exchanger designs that push the boundaries of thermal management and deliver superior performance in a wide range of applications.

Challenges and Considerations

While the integration of microfluidics and two-phase flow holds immense promise, it also presents a unique set of challenges that must be carefully addressed. One of the primary concerns is the increased complexity associated with the design, manufacturing, and operation of these advanced heat exchanger systems.

The precise control of fluid flow and heat transfer within microscale channels requires a deep understanding of the underlying fluid mechanics and heat transfer phenomena. This necessitates extensive research, modeling, and experimental validation to ensure reliable and predictable performance.

Moreover, the management of two-phase flow instabilities, such as flow boiling crisis and flow reversal, becomes increasingly critical at the microscale. Addressing these challenges requires innovative approaches to flow stabilization, active control mechanisms, and enhanced heat transfer surfaces.

In addition, the integration of these advanced heat exchanger technologies into existing industrial and commercial systems may pose logistical and economic challenges. Factors such as cost, scalability, and compatibility with existing infrastructure must be carefully considered to enable widespread adoption and successful implementation.

Conclusion: Unlocking the Future of Air-Cooled Heat Exchangers

The integration of microfluidics and two-phase flow has the potential to revolutionize the design and performance of air-cooled heat exchangers. By harnessing the unique advantages of these emerging fields, engineers can develop innovative thermal management solutions that push the boundaries of efficiency, compact size, and high-performance cooling.

As the industry continues to evolve, the exploration of microfluidics and two-phase flow will undoubtedly play a crucial role in shaping the future of air-cooled heat exchanger technology. By addressing the challenges and capitalizing on the opportunities, we can unlock new frontiers in thermal engineering and deliver game-changing advancements that transform the way we manage heat in a wide range of applications.

To stay informed on the latest developments and insights in the world of air-cooled heat exchangers, be sure to visit https://www.aircooledheatexchangers.net/, the leading destination for industry professionals and enthusiasts alike.