As the electric vehicle (EV) and hybrid electric vehicle (HEV) market continues to experience rapid growth, effective thermal management has become a critical factor in ensuring the safety, efficiency, and longevity of these advanced powertrain systems. At the forefront of this challenge are innovative air-cooled heat exchanger technologies that are revolutionizing the way thermal energy is managed in EVs and HEVs.

Optimizing Battery Thermal Management

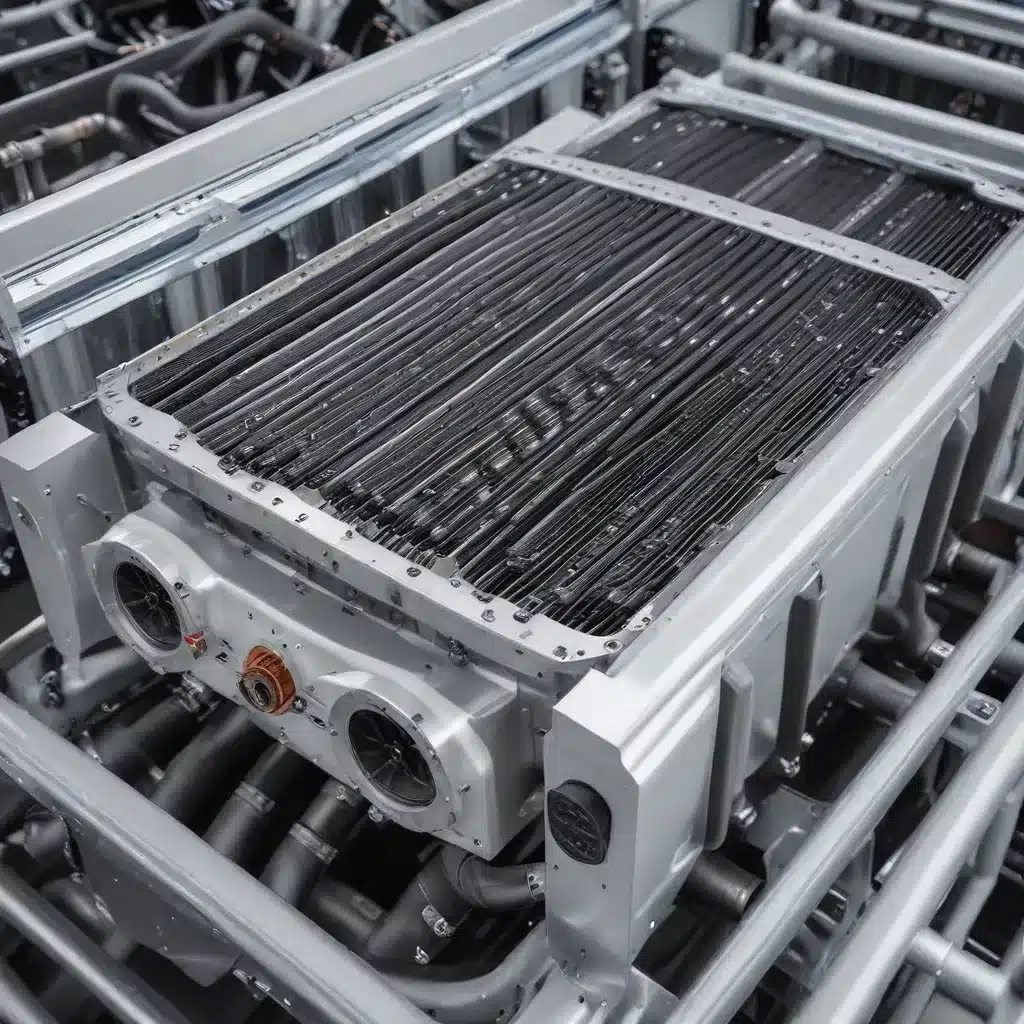

The heart of any EV or HEV is its lithium-ion battery pack, which must operate within a narrow temperature range to maintain optimal performance, durability, and safety. Innovative air-cooled heat exchangers are playing a pivotal role in this regard, providing efficient and reliable thermal control for battery systems.

Fluxless Aluminum Brazing for Battery Cooling

One notable advancement in air-cooled heat exchanger technology is the development of fluxless aluminum brazing processes. This clean manufacturing technique, pioneered by companies like Dana PTG, Thermal Products, has enabled the production of highly efficient battery cooling heat exchangers.

Through collaborative research with academic institutions, these advanced fluxless brazing processes have been further refined to enhance braze performance, improve environmental sustainability, and optimize cost-effectiveness. The resulting heat exchangers not only effectively dissipate the heat generated by battery charging and discharging but also incorporate innovative features like integrated sol-gel thick film heaters to improve battery performance in cold environments.

Comprehensive Battery Thermal Management Strategies

To achieve comprehensive thermal management, EV and HEV manufacturers are increasingly integrating air-cooled heat exchangers with other thermal control systems, such as:

- Active Thermal Regulation: Incorporating smart control algorithms and sensors to actively monitor and adjust the cooling system’s performance based on real-time battery usage and environmental conditions.

- Thermal Energy Storage: Utilizing phase-change materials or thermal energy storage systems to capture and release heat as needed, improving overall thermal management efficiency.

- Multi-Stage Cooling: Employing a combination of air-cooled and liquid-cooled heat exchangers to create a hybrid thermal management solution that maximizes cooling capacity and flexibility.

By taking a holistic approach to battery thermal management, manufacturers can ensure optimal performance, safety, and longevity for their EV and HEV battery systems.

Enhancing Motor Thermal Management

In addition to battery thermal management, air-cooled heat exchangers play a crucial role in managing the thermal challenges associated with electric motors and power electronics in EVs and HEVs.

Efficient Motor Cooling

Electric motors, which are at the heart of the powertrain, generate significant amounts of heat during operation. Effective cooling is essential to maintain motor efficiency, prevent overheating, and extend the motor’s lifespan. Innovative air-cooled heat exchanger designs, often incorporating advanced fin geometries and high-performance materials, are engineered to efficiently dissipate this heat, ensuring optimal motor performance.

Integrating Thermal Management Systems

Just as with battery thermal management, a comprehensive approach to motor thermal management involves integrating air-cooled heat exchangers with other thermal control systems, such as:

- Active Cooling Control: Implementing advanced control algorithms and sensors to dynamically adjust the cooling system based on motor load, speed, and environmental conditions.

- Waste Heat Utilization: Capturing and repurposing the waste heat generated by the motor to contribute to the overall vehicle’s thermal management, such as cabin heating or battery thermal regulation.

- Hybrid Cooling Architectures: Combining air-cooled and liquid-cooled heat exchangers to create a versatile and adaptable thermal management system that can handle a wide range of operating conditions.

By optimizing the integration of air-cooled heat exchangers within the broader thermal management ecosystem, manufacturers can maximize the efficiency, reliability, and performance of EV and HEV electric motors.

Integrating Air-Cooled Heat Exchangers for Comprehensive Thermal Management

The advancement of air-cooled heat exchanger technologies has enabled a more holistic approach to thermal management in EVs and HEVs. By seamlessly integrating these innovative solutions into the design of battery, motor, and other critical subsystems, manufacturers can achieve unprecedented levels of thermal control and energy efficiency.

Comprehensive System Integration

A well-designed thermal management system in an EV or HEV should incorporate air-cooled heat exchangers that are strategically integrated with other thermal control components, such as:

- Air conditioning (AC) systems: Leveraging the air-cooling capabilities of heat exchangers to optimize the performance and efficiency of the vehicle’s climate control system.

- Regenerative braking systems: Capturing and dissipating the thermal energy generated during braking to improve overall energy utilization.

- Cabin heating and ventilation: Utilizing waste heat from various powertrain components to provide efficient cabin heating, reducing the need for energy-intensive electric or fuel-based heating systems.

By seamlessly integrating air-cooled heat exchangers into this broader thermal management ecosystem, manufacturers can ensure optimal energy utilization, enhanced passenger comfort, and improved overall vehicle performance.

Intelligent Control Algorithms

Maximizing the efficiency and effectiveness of a comprehensive thermal management system requires the implementation of advanced control algorithms. These intelligent control systems utilize a network of sensors, actuators, and sophisticated software to continuously monitor and adjust the various thermal subsystems, ensuring optimal performance under diverse driving conditions and environmental factors.

Key features of these intelligent control algorithms include:

- Predictive Thermal Modeling: Leveraging machine learning and artificial intelligence to anticipate thermal loads and proactively adjust the cooling system’s response.

- Adaptive Load Balancing: Dynamically allocating thermal management resources based on real-time demands from different subsystems, ensuring no single component is over- or under-cooled.

- Integrated Diagnostics: Continuously monitoring the health and performance of the thermal management system, identifying potential issues, and triggering preventive maintenance actions.

By integrating these advanced control strategies with innovative air-cooled heat exchanger technologies, EV and HEV manufacturers can optimize the overall thermal management system, maximizing energy efficiency, reliability, and driving experience for their customers.

Conclusion

As the electric and hybrid vehicle market continues to evolve, the role of air-cooled heat exchanger technologies in enhancing thermal management has become increasingly critical. From optimizing battery and motor cooling to seamlessly integrating these solutions within a comprehensive thermal management ecosystem, innovative advancements in air-cooled heat exchanger design and manufacturing are paving the way for a new era of EV and HEV performance and efficiency.

By leveraging the expertise of industry leaders like Dana PTG, Thermal Products and collaborating with academic institutions, manufacturers can continue to push the boundaries of what’s possible in thermal management, ultimately delivering safer, more reliable, and more energy-efficient electric and hybrid vehicles to consumers worldwide.