The Evolving Landscape of Air-Cooled Heat Exchangers

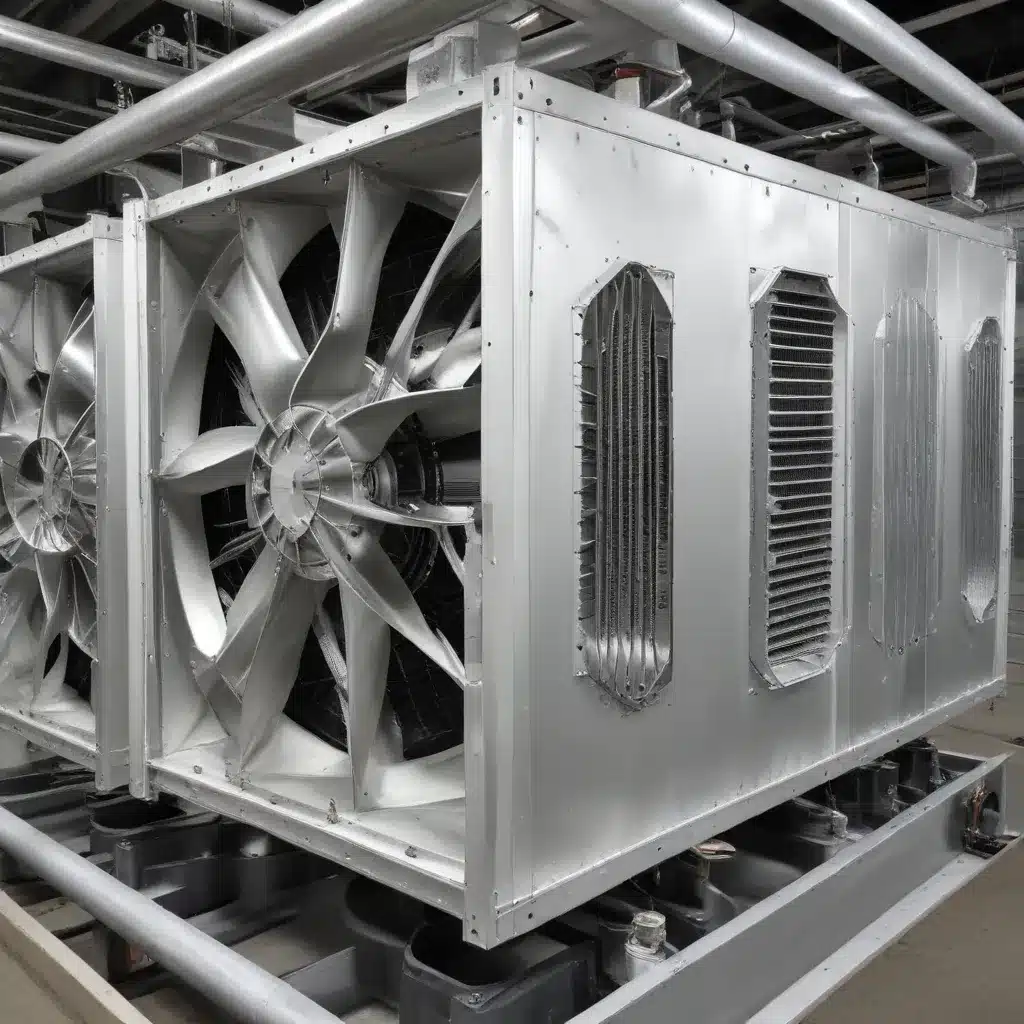

As industries across the spectrum strive for greater energy efficiency and sustainability, the critical role of air-cooled heat exchangers has come into sharp focus. These versatile and reliable thermal management components are at the heart of countless industrial processes, from power generation and transportation to HVAC systems and beyond. However, the demands placed on air-cooled heat exchangers have evolved, requiring innovative design approaches to meet the ever-increasing challenges of modern thermal management.

In this comprehensive article, we will delve into the pioneering advancements that are redefining the capabilities of air-cooled heat exchangers. By exploring the latest design innovations, engineering breakthroughs, and performance optimization strategies, we will uncover the key insights that are driving the future of this crucial technology.

Unlocking the Potential of Air-Cooled Heat Exchangers

Air-cooled heat exchangers have long been the workhorse of thermal management systems, offering a reliable and cost-effective solution for a wide range of applications. However, as industries strive for greater energy efficiency and sustainability, the performance demands placed on these heat exchangers have escalated. From improving heat transfer rates and reducing energy consumption to enhancing reliability and extending service life, the design and engineering of air-cooled heat exchangers have undergone a transformative evolution.

One of the primary drivers of this evolution is the growing emphasis on energy efficiency and environmental impact. As global concerns over climate change and resource conservation continue to rise, industries are under increasing pressure to optimize their energy usage and minimize their carbon footprint. This has prompted a renewed focus on the design and development of air-cooled heat exchangers that can deliver superior thermal management capabilities while minimizing energy consumption.

Innovative Design Approaches for Enhanced Performance

At the forefront of this evolution are cutting-edge design approaches that are reshaping the capabilities of air-cooled heat exchangers. From the incorporation of advanced materials and coatings to the optimization of airflow patterns and heat transfer mechanisms, these innovations are unlocking new levels of efficiency and performance.

Advanced Materials and Coatings

One of the key advancements in air-cooled heat exchanger design is the integration of innovative materials and surface coatings. By carefully selecting the right materials and applying specialized coatings, engineers can dramatically improve the heat transfer capabilities, corrosion resistance, and overall durability of these critical components.

Ceramic Coatings: The use of ceramic coatings on heat exchanger surfaces has emerged as a game-changing innovation. These advanced coatings not only enhance heat transfer rates but also provide superior protection against corrosion, erosion, and fouling. The improved heat transfer characteristics of ceramic-coated heat exchangers can result in significant energy savings, as less power is required to maintain the desired thermal management performance.

Nano-Structured Surfaces: Another promising advancement in air-cooled heat exchanger design is the incorporation of nano-structured surfaces. These engineered surfaces, featuring microscopic patterns and textures, can dramatically improve the wettability and heat transfer properties of the heat exchanger. By leveraging the unique properties of nano-scale structures, engineers can optimize the heat transfer processes, leading to enhanced thermal management capabilities.

Lightweight and High-Strength Materials: In addition to improved thermal performance, the design of air-cooled heat exchangers must also consider factors such as weight, durability, and manufacturing efficiency. Innovative lightweight and high-strength materials, such as aluminum alloys and advanced composites, are now being utilized to create heat exchangers that are more compact, easier to install, and less energy-intensive to operate.

Optimized Airflow and Heat Transfer

Another critical aspect of air-cooled heat exchanger design is the optimization of airflow patterns and heat transfer mechanisms. By carefully engineering the geometry, fin configurations, and air distribution systems, engineers can unlock significant improvements in thermal management performance.

Fin Designs: The design of heat exchanger fins has a profound impact on the overall heat transfer efficiency. Advanced fin geometries, such as wavy, louvered, or offset-strip fins, can enhance the turbulence and mixing of the airflow, leading to improved heat transfer coefficients and reduced pressure drops. These innovative fin designs not only boost thermal performance but also enable more compact and lightweight heat exchanger configurations.

Airflow Optimization: The efficient distribution and management of airflow across the heat exchanger surface is crucial for maximizing thermal performance. Techniques such as computational fluid dynamics (CFD) modeling, wind tunnel testing, and advanced air-flow simulations are being employed to optimize the air inlet and outlet designs, fan configurations, and flow management strategies. By optimizing the airflow patterns, engineers can minimize pressure drops, reduce energy consumption, and achieve higher heat transfer rates.

Advanced Heat Transfer Mechanisms: Beyond the optimization of airflow, researchers and engineers are also exploring innovative heat transfer mechanisms to enhance the performance of air-cooled heat exchangers. This includes the integration of phase change materials (PCMs), which can store and release latent heat to improve thermal management capabilities, as well as the utilization of thermoelectric cooling technologies that can provide precise temperature control and bidirectional heat transfer.

Improving Maintenance and Reliability

Alongside the advancements in design and engineering, the maintenance and reliability of air-cooled heat exchangers have also become a critical focus area. As these components play a vital role in the overall efficiency and uptime of industrial processes, ensuring their long-term performance and minimizing maintenance requirements is paramount.

Innovative Cleaning and Fouling Prevention

One of the primary challenges in maintaining air-cooled heat exchangers is the accumulation of fouling deposits on the heat transfer surfaces. These deposits, which can include dust, debris, and chemical residues, can significantly impair the heat transfer capabilities and lead to increased energy consumption and reduced system efficiency.

To address this challenge, engineers are developing innovative cleaning and fouling prevention strategies. Automated cleaning systems, such as robotic brushes or high-pressure water jets, can be integrated into the heat exchanger design to periodically remove accumulated deposits, ensuring optimal heat transfer performance without the need for manual intervention.

Additionally, the use of self-cleaning coatings and hydrophobic/superhydrophobic surfaces is gaining traction in the air-cooled heat exchanger industry. These advanced surface treatments can prevent the adhesion of fouling deposits, making it easier to maintain the heat exchanger’s cleanliness and thermal efficiency over extended periods of operation.

Predictive Maintenance and Condition Monitoring

Another critical aspect of improving the reliability and longevity of air-cooled heat exchangers is the adoption of predictive maintenance and condition monitoring strategies. By leveraging advanced sensors, data analytics, and machine learning algorithms, operators can now monitor the real-time performance and health of their heat exchangers, allowing them to plan and execute maintenance tasks proactively.

Sensor-Based Monitoring: Integrating a network of sensors, such as temperature, pressure, and vibration sensors, into the heat exchanger design enables the continuous monitoring of its operating conditions. By analyzing this sensor data, operators can detect early signs of degradation, fouling, or impending failures, allowing them to intervene before major issues arise.

Predictive Maintenance Models: Combining sensor data with historical performance records and advanced analytics, engineers can develop predictive maintenance models that forecast the remaining useful life of air-cooled heat exchangers. These models can help operators schedule maintenance activities, optimize spare parts inventory, and minimize unplanned downtime, ultimately improving the overall reliability and cost-effectiveness of their thermal management systems.

Advancements in Industrial Applications

The impact of the latest innovations in air-cooled heat exchanger design and engineering is being felt across a wide range of industrial sectors, each with its own unique thermal management challenges and requirements. From power generation and transportation to data centers and HVAC systems, these advancements are driving significant improvements in energy efficiency, sustainability, and operational reliability.

Power Generation and Energy Production

In the power generation industry, air-cooled heat exchangers play a critical role in the cooling and thermal management of various components, from steam turbines and generators to heat recovery systems. The incorporation of advanced materials, optimized airflow designs, and predictive maintenance strategies has enabled power plant operators to enhance the efficiency and reliability of their thermal management systems, ultimately improving the overall performance and environmental impact of their facilities.

Transportation and Mobility

The transportation sector, particularly in the rapidly evolving electric vehicle (EV) industry, has seen a surge of innovation in air-cooled heat exchanger design. As EV manufacturers strive to maximize driving range and energy efficiency, the thermal management of batteries, motors, and other critical components has become a crucial focus area. The development of advanced heat pump systems, like the world’s first 4th generation heat pump system introduced by Hanon Systems, has revolutionized the way EVs manage their thermal loads, leading to significant improvements in energy efficiency and driving range.

Data Centers and HVAC Systems

The growing demand for energy-efficient and reliable cooling solutions in data centers and HVAC systems has also driven advancements in air-cooled heat exchanger design. By leveraging innovative materials, optimized airflow patterns, and predictive maintenance strategies, engineers are developing heat exchangers that can meet the stringent thermal management requirements of these applications while minimizing energy consumption and environmental impact.

Charting the Future of Air-Cooled Heat Exchangers

As the demands placed on thermal management systems continue to evolve, the air-cooled heat exchanger industry is at the forefront of a transformative revolution. The pioneering advancements in design, engineering, and maintenance practices are unlocking new levels of energy efficiency, reliability, and sustainability, paving the way for a future where air-cooled heat exchangers play an even more crucial role in powering the world’s industries.

By embracing the latest innovations, industries across the spectrum can optimize their thermal management capabilities, reduce their environmental footprint, and enhance the overall performance and longevity of their critical systems. As we continue to push the boundaries of what is possible in air-cooled heat exchanger design, the future holds immense promise for a more efficient, sustainable, and resilient thermal management landscape.

To stay informed on the latest advancements and trends shaping the air-cooled heat exchanger industry, be sure to explore the resources and insights available on Air Cooled Heat Exchangers. Our team of experts is dedicated to providing you with the knowledge and tools you need to navigate the evolving landscape of this crucial technology.