In the world of thermal engineering, optimizing the performance of air-cooled heat exchangers is a constant challenge faced by industry experts. These critical components play a vital role in a wide range of applications, from power generation and industrial manufacturing to HVAC systems and refrigeration. As the demand for efficient and cost-effective heat transfer solutions continues to grow, the need for innovative strategies to enhance heat transfer has become increasingly important.

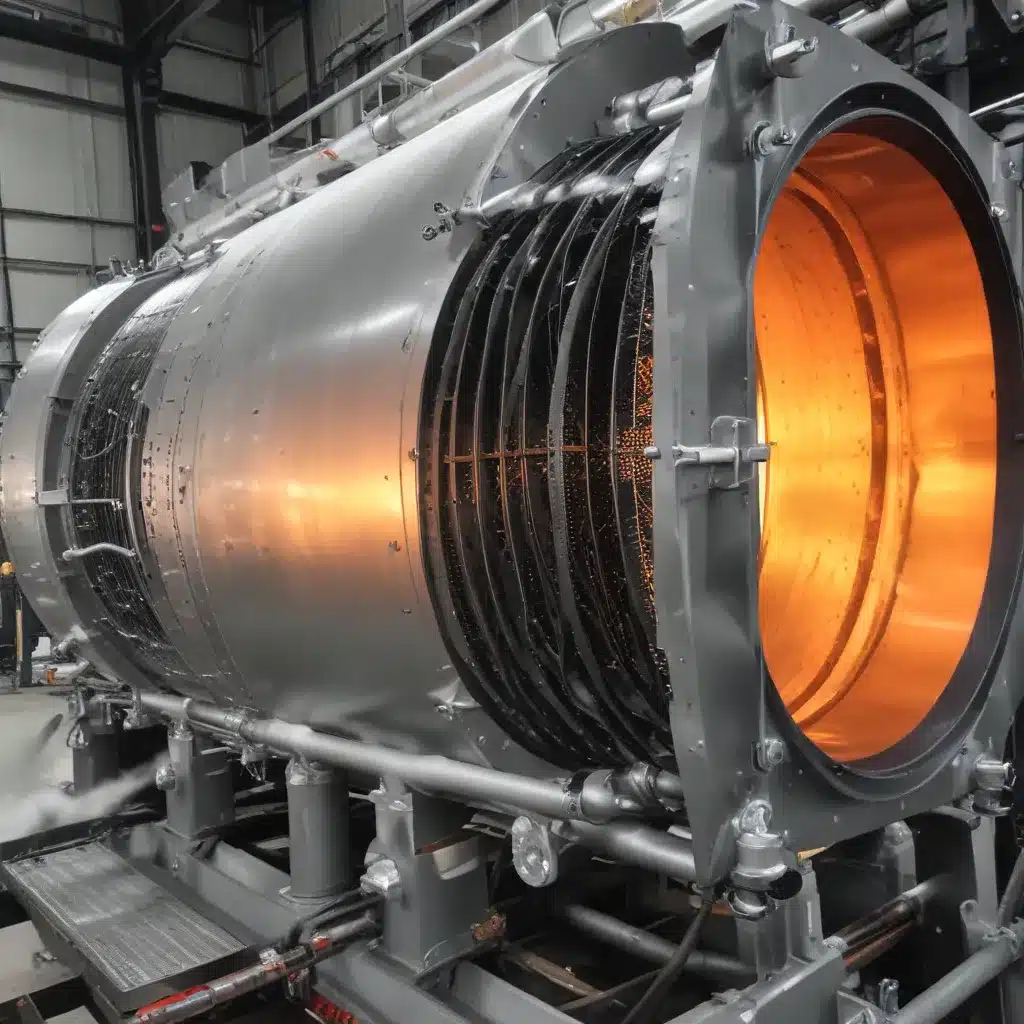

One promising approach to improving the thermal performance of air-cooled heat exchangers is the strategic use of turbulence promoters and flow enhancers. These advanced techniques can significantly boost the heat transfer rates within the heat exchanger, leading to improved overall efficiency and reduced operational costs.

Understanding the Importance of Turbulence Promotion

The heat transfer process in air-cooled heat exchangers is heavily influenced by the fluid dynamics within the system. Laminar flow, which is characterized by smooth, orderly fluid motion, can often hinder the heat transfer process. In contrast, turbulent flow, marked by chaotic and irregular fluid movements, can dramatically enhance the heat transfer rate.

By incorporating turbulence promoters, such as strategically placed ribs or fins, heat exchanger designers can actively disrupt the laminar boundary layer and induce higher levels of turbulence. This turbulence promotes better mixing of the fluid, leading to increased convective heat transfer coefficients and, ultimately, enhanced overall heat transfer performance.

The Impact of Rib Angle on Heat Transfer

One of the key factors in the design of turbulence promoters is the angle of the ribs relative to the main flow direction. A team of researchers from Texas A&M University conducted a comprehensive study on the effects of rib angle on heat transfer and pressure drop in a square duct with rib-roughened walls.

Their findings revealed that angled ribs, with angles ranging from 45 to 30 degrees, can provide a significant performance advantage over the more commonly used 90-degree transverse ribs. The researchers found that the increased heat transfer conductance for the angled ribs was approximately 10-20% higher than the 90-degree ribs, while the pumping power requirement was 20-50% lower.

This is a crucial insight for heat exchanger designers, as it demonstrates that carefully selecting the rib angle can lead to substantial improvements in both thermal and hydraulic performance. By optimizing the rib geometry, heat exchanger efficiency can be enhanced without incurring disproportionate penalties in terms of pressure drop and pumping power.

Combining Turbulence Promoters with Flow Enhancers

While turbulence promoters play a vital role in enhancing heat transfer, they can be further complemented by the use of flow enhancers. These specialized features are designed to manipulate the fluid flow patterns within the heat exchanger, ensuring more effective utilization of the available heat transfer surface area.

One example of a flow enhancer is the use of vortex generators. These small, angled winglets or tabs are strategically placed within the heat exchanger, creating localized vortices that disrupt the boundary layer and promote increased mixing of the fluid. By creating these swirling flow patterns, vortex generators can significantly boost the convective heat transfer coefficient, leading to improved overall thermal performance.

Another flow enhancement technique is the incorporation of dimpled surfaces. These small, concave indentations on the heat transfer surfaces create turbulent flow and enhance the turbulent mixing of the fluid, leading to higher local heat transfer coefficients. The research conducted by the National Energy Technology Laboratory has shown that dimpled surfaces can provide up to a 30% increase in the Nusselt number (a dimensionless parameter that characterizes heat transfer) compared to smooth surfaces.

Optimizing Heat Exchanger Design with Advanced Techniques

When designing high-performance air-cooled heat exchangers, it is crucial to consider the synergistic effects of turbulence promoters and flow enhancers. By carefully selecting and integrating these advanced features, heat exchanger designers can unlock the full potential of their systems, achieving remarkable improvements in thermal efficiency and overall operational performance.

For example, a recent study published in the International Journal of Heat and Mass Transfer explored the use of combined turbulence promoters and flow enhancers in air-cooled heat exchangers. The researchers found that the integration of angled ribs and vortex generators resulted in a heat transfer enhancement of up to 35% compared to a baseline smooth-surface configuration, with only a moderate increase in pressure drop.

This demonstrates the power of a holistic approach to heat exchanger design, where multiple advanced techniques are strategically combined to achieve exceptional thermal performance without sacrificing energy efficiency or operational costs.

Exploring Industrial Applications and Maintenance Considerations

The benefits of incorporating turbulence promoters and flow enhancers in air-cooled heat exchangers extend across a wide range of industries, including power generation, petrochemical processing, HVAC systems, and refrigeration.

In the power generation sector, for instance, air-cooled heat exchangers play a critical role in the cooling of turbine components, enabling efficient and reliable electricity production. By optimizing the heat transfer performance of these systems, power plant operators can achieve significant improvements in overall efficiency, reducing fuel consumption and lowering operational costs.

Similarly, in the petrochemical industry, air-cooled heat exchangers are essential for the cooling and condensation of various process streams. Enhancing the heat transfer capabilities of these exchangers can lead to increased production yields, reduced energy demands, and improved environmental sustainability.

However, it is important to note that the integration of advanced turbulence promoters and flow enhancers may also introduce additional maintenance considerations. These specialized features can be more susceptible to fouling and clogging, which can compromise their effectiveness over time. Regular inspection, cleaning, and maintenance procedures are crucial to ensure the long-term reliable operation of air-cooled heat exchangers equipped with these technologies.

Conclusion: Unlocking the Full Potential of Air-Cooled Heat Exchangers

As the demand for efficient and sustainable thermal management solutions continues to grow, the strategic use of turbulence promoters and flow enhancers in air-cooled heat exchangers has emerged as a powerful strategy for driving performance improvements. By leveraging the synergistic effects of these advanced techniques, heat exchanger designers can unlock remarkable gains in heat transfer rates, energy efficiency, and overall system optimization.

Whether you’re working in the power generation, petrochemical, or any other industry that relies on air-cooled heat exchangers, staying informed about the latest advancements in turbulence promotion and flow enhancement is essential. By embracing these innovative approaches, you can position your organization at the forefront of thermal engineering, delivering cutting-edge solutions that meet the evolving needs of the market.

To learn more about the latest developments in air-cooled heat exchanger technology, we encourage you to explore the wealth of resources available on our website. Our team of industry experts is dedicated to providing practical guidance, in-depth insights, and real-world case studies to help you optimize the performance of your air-cooled heat exchangers and stay ahead of the curve.