As a seasoned expert in the world of air-cooled heat exchangers, I’m excited to share insights and practical tips that can help optimize heat transfer performance and unlock new possibilities in thermal management. In this comprehensive article, we’ll delve into the latest advancements in tube designs and explore how they are revolutionizing the efficiency and versatility of air-cooled heat exchangers across various industries.

Understanding the Importance of Air-Cooled Heat Exchangers

Air-cooled heat exchangers play a crucial role in a wide range of applications, from industrial processes and power generation to HVAC systems and transportation. These robust, versatile devices facilitate the transfer of thermal energy between a hot fluid or gas and the surrounding air, enabling efficient cooling or heating as required. Their ability to operate without the need for water-based cooling systems makes them an attractive choice in regions with limited water availability or where water usage needs to be minimized.

However, the performance of air-cooled heat exchangers is inherently limited by the relatively low thermal conductivity and heat transfer coefficient of air compared to liquids. This challenge has driven engineers and researchers to continuously explore innovative tube designs that can enhance heat transfer and improve the overall efficiency of these crucial thermal management components.

Innovative Tube Designs for Enhanced Heat Transfer

Louvered Fin Tubes

One of the most prominent advancements in air-cooled heat exchanger technology is the use of louvered fin tubes. These tubes feature a series of small, angled fins that disrupt the airflow, creating turbulence and increasing the surface area available for heat transfer. Louvered fin tubes have been shown to enhance the heat transfer coefficient by up to 30% compared to traditional smooth-surfaced tubes, making them a highly effective solution for improving the thermal performance of air-cooled heat exchangers.

The unique design of louvered fin tubes disrupts the boundary layer, promoting better mixing of the air and creating more efficient heat exchange. This not only enhances the overall heat transfer rate but also reduces the pressure drop across the heat exchanger, leading to energy savings and improved system efficiency.

Wavy Fin Tubes

Another innovative tube design gaining traction in the air-cooled heat exchanger market is the wavy fin tube. These tubes feature a sinusoidal or undulating fin pattern, which helps to increase the surface area and promote complex airflow patterns that enhance heat transfer. Compared to traditional straight-fin tubes, wavy fin tubes can improve heat transfer by up to 20%, making them a compelling option for applications where space constraints or weight limitations are a concern.

The wavy fin design creates a secondary flow, which disrupts the boundary layer and generates vortices that mix the air more effectively. This increased turbulence and air-side heat transfer coefficient result in higher overall thermal performance, making wavy fin tubes a versatile choice for a variety of air-cooled heat exchanger applications.

Internally Finned Tubes

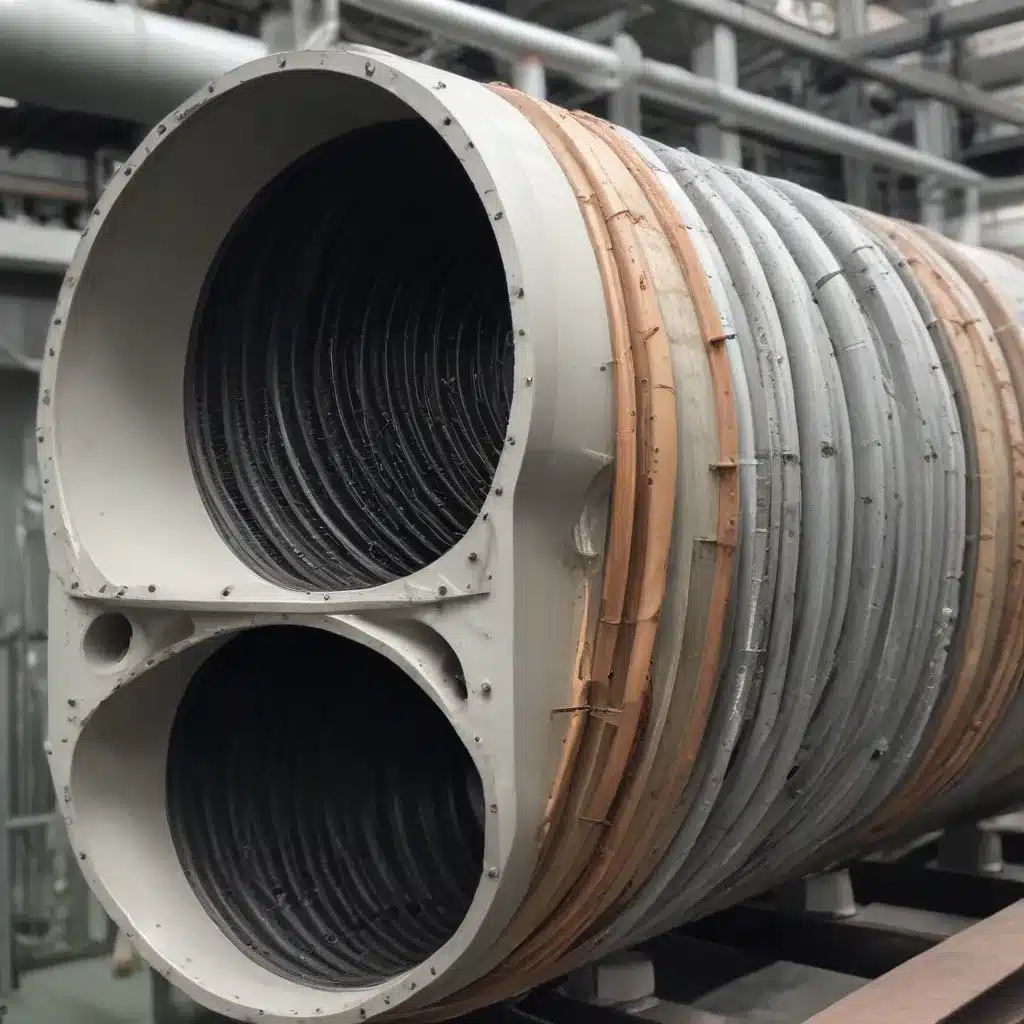

While external fin designs have been the primary focus of innovation, advancements in internally finned tubes have also shown promising results for enhancing heat transfer in air-cooled heat exchangers. These tubes feature a series of small, spiral-shaped fins or ridges on the inner surface, which increase the surface area and promote more efficient heat transfer between the fluid and the tube wall.

The internal fins create turbulence and disrupt the boundary layer within the tube, leading to improved heat transfer on the fluid side. This, in turn, can enhance the overall thermal performance of the air-cooled heat exchanger, particularly in applications where the fluid-side heat transfer coefficient is a limiting factor.

Hybrid Tube Designs

To further push the boundaries of heat transfer performance, researchers and engineers have explored the development of hybrid tube designs that combine multiple innovative features. For example, some air-cooled heat exchanger designs incorporate both louvered fins and internal fins, leveraging the synergistic benefits of these technologies to achieve even greater thermal efficiency.

These hybrid tube designs often require more complex manufacturing processes, but the potential for significant performance improvements makes them an attractive option for specialized applications where maximizing heat transfer is of paramount importance.

Factors to Consider When Selecting Innovative Tube Designs

When choosing the right innovative tube design for an air-cooled heat exchanger, there are several key factors to consider:

-

Application Requirements: The specific thermal management needs, operating conditions, and constraints of the target application should guide the selection of the appropriate tube design. For example, wavy fin tubes may be more suitable for space-constrained applications, while louvered fins may be better suited for high-heat-flux scenarios.

-

Heat Transfer Performance: Evaluate the expected improvements in heat transfer coefficient, thermal efficiency, and overall heat exchanger effectiveness that the innovative tube design can provide. This information can help to quantify the potential benefits and justify the investment in these advanced technologies.

-

Pressure Drop and Airflow Considerations: The impact of the tube design on air-side pressure drop and the corresponding energy requirements for airflow should be carefully assessed. Maintaining a balance between heat transfer enhancement and acceptable pressure drop is crucial for system-level optimization.

-

Manufacturability and Cost: The complexity and production costs associated with the innovative tube design must be taken into account, as these factors can influence the overall feasibility and economic viability of the air-cooled heat exchanger solution.

-

Maintenance and Reliability: The ease of cleaning, servicing, and maintaining the heat exchanger with the selected tube design is an important consideration, as it can impact the long-term performance and operational costs of the system.

By thoroughly evaluating these factors, you can make informed decisions and select the innovative tube design that best aligns with the specific requirements and constraints of your air-cooled heat exchanger application.

Integrating Innovative Tube Designs into Air-Cooled Heat Exchanger Solutions

At https://www.aircooledheatexchangers.net/, we are committed to staying at the forefront of air-cooled heat exchanger technology, continuously incorporating the latest advancements in tube designs to deliver superior thermal management solutions.

Our team of experienced engineers and thermal specialists work closely with our clients to understand their unique challenges and requirements, and then leverage our expertise to design and integrate the most appropriate innovative tube technologies. Whether it’s louvered fins, wavy fins, or hybrid designs, we ensure that the selected solution optimizes heat transfer, minimizes energy consumption, and meets the specific needs of each application.

Through our rigorous testing and evaluation processes, we can provide our clients with reliable performance data, expert guidance, and tailored recommendations to help them make informed decisions and navigate the evolving landscape of air-cooled heat exchanger technology.

Conclusion

As the demand for efficient and sustainable thermal management solutions continues to grow, the development of innovative tube designs for air-cooled heat exchangers has become a critical area of focus. By leveraging advanced technologies like louvered fins, wavy fins, and hybrid designs, we can unlock new levels of heat transfer performance, leading to improved energy efficiency, reduced environmental impact, and enhanced system reliability.

By staying at the forefront of these advancements and working closely with our clients, we are poised to help businesses across various industries harness the full potential of air-cooled heat exchangers and drive the future of thermal management. If you’re interested in exploring how innovative tube designs can benefit your application, I encourage you to connect with our team of experts at https://www.aircooledheatexchangers.net/. Together, we can embark on a journey of enhanced heat transfer and unlock new possibilities for your thermal management needs.