As a seasoned expert in the field of air-cooled heat exchangers, I am excited to share my insights on the latest advancements in fin design and geometry that can significantly enhance heat transfer performance. Air-cooled heat exchangers are ubiquitous in various industries, from HVAC systems and automotive applications to aerospace and renewable energy, thanks to their compact size, lightweight construction, and efficient heat transfer capabilities.

The Importance of Fin Design in Air-Cooled Heat Exchangers

The fins in an air-cooled heat exchanger play a crucial role in facilitating heat transfer between the fluid (typically air) and the heat exchanger surfaces. By increasing the surface area exposed to the air, fins enhance the convective heat transfer coefficient, resulting in more efficient heat dissipation. However, the design of these fins can significantly impact the overall performance of the heat exchanger.

Conventional Fin Geometries

Traditionally, air-cooled heat exchangers have employed rectangular or circular fin geometries. These straightforward designs provide a solid foundation for heat transfer, but they are often limited in their ability to maximize efficiency. Researchers have explored various innovative fin shapes and configurations to push the boundaries of heat transfer enhancement.

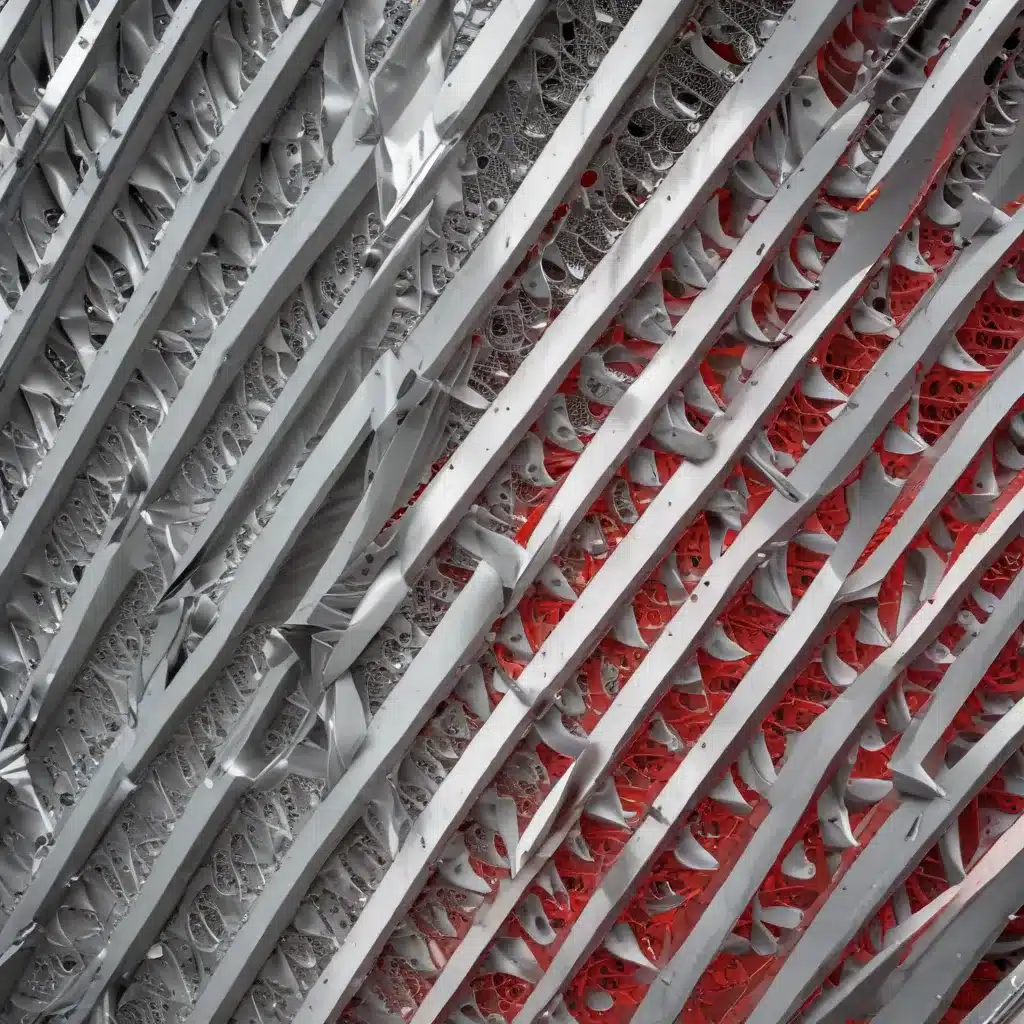

Wavy Fin Designs

One of the prominent advancements in air-cooled heat exchanger technology is the introduction of wavy fin geometries. These fins feature a sinusoidal or undulating pattern that creates turbulence in the airflow, disrupting the boundary layer and improving convective heat transfer. The strategic placement of these wavy fins can result in a significant increase in heat transfer rates, often by 20% or more compared to traditional rectangular fins.

Serrated Fin Designs

Another innovative fin geometry that has gained traction is the serrated or louvered fin design. These fins feature a series of small, angled louvers or serrations that create additional turbulence and air disruption, further enhancing heat transfer. The strategic placement and orientation of these serrations can optimize airflow and heat exchange, leading to substantial performance improvements, often in the range of 15-25% over conventional fin designs.

Microchannel Fin Designs

The concept of microchannel heat exchangers has revolutionized the field of air-cooled heat transfer. These heat exchangers feature extremely small flow channels and fins, often in the range of a few millimeters or less. By reducing the size of the flow passages, the surface area-to-volume ratio is significantly increased, resulting in enhanced heat transfer. Microchannel heat exchangers have found applications in electronics cooling, automotive air conditioning, and high-performance computing, where their compact size and high efficiency are highly valued.

Computational Fluid Dynamics (CFD) Optimization

The advancement of computational fluid dynamics (CFD) software has played a pivotal role in the optimization of air-cooled heat exchanger designs. Engineers can now simulate and analyze the intricate fluid flow and heat transfer dynamics within these heat exchangers with unprecedented accuracy. This enables the development of highly efficient fin geometries and the optimization of existing systems, leading to significant performance improvements.

CFD-Driven Fin Design Optimization

By leveraging CFD simulations, engineers can explore a wide range of fin geometries, configurations, and arrangements to identify the most effective designs for specific applications. This includes evaluating the impact of fin spacing, thickness, and orientation on heat transfer rates, pressure drop, and overall thermal-hydraulic performance. The ability to virtually test and optimize fin designs before physical prototyping is a game-changer in the field of air-cooled heat exchanger development.

Validation and Benchmarking

Alongside the optimization process, CFD simulations play a crucial role in validating the performance of air-cooled heat exchangers. By comparing the predicted results from CFD models with experimental data or field observations, engineers can ensure the accuracy and reliability of their designs. This validation process helps build confidence in the use of innovative fin geometries and the ability to achieve the desired heat transfer performance in real-world applications.

Material Innovations and Advancements

In addition to the advancements in fin design and geometry, the materials used in air-cooled heat exchangers have also evolved, further enhancing their capabilities. The introduction of advanced materials, such as graphene-enhanced composites, has improved thermal conductivity and durability, opening up new possibilities for high-performance heat exchangers in demanding environments.

Graphene-Enhanced Composites

Graphene, a two-dimensional allotrope of carbon, has demonstrated exceptional thermal and electrical properties. By incorporating graphene into the materials used for heat exchanger fins and other components, engineers can significantly improve the overall thermal conductivity of the system. This enhancement in thermal transport capabilities can lead to more efficient heat dissipation and improved overall performance of the air-cooled heat exchanger.

Additive Manufacturing and 3D Printing

The rise of additive manufacturing and 3D printing technologies has also impacted the field of air-cooled heat exchangers. These advanced manufacturing techniques enable the creation of intricate fin geometries and flow passages that would be challenging or even impossible to produce using traditional manufacturing methods. This opens up new design possibilities, allowing for the integration of complex, optimized fin structures that can further enhance heat transfer performance.

Maintenance and Optimization Strategies

Maintaining the optimal performance of air-cooled heat exchangers is crucial, as they are often critical components in various industrial processes. Regular maintenance and optimization strategies can help ensure the long-term efficiency and reliability of these heat exchangers.

Fouling and Cleaning

One of the primary maintenance considerations for air-cooled heat exchangers is the accumulation of fouling on the fin surfaces. Dust, debris, and other contaminants can build up over time, reducing the heat transfer efficiency. Implementing regular cleaning procedures, such as the use of high-pressure air or water, can help maintain the cleanliness of the fins and restore the heat exchanger’s performance.

Airflow Optimization

Ensuring optimal airflow through the heat exchanger is essential for maximizing heat transfer. Factors such as fan speed, duct design, and air inlet/outlet configurations can significantly impact the airflow patterns and, consequently, the overall heat transfer performance. Periodic reviews and adjustments to the airflow system can help maintain the desired level of heat exchange.

Monitoring and Performance Tracking

Regularly monitoring the performance of air-cooled heat exchangers, such as tracking temperature differentials, pressure drops, and overall heat transfer rates, can provide valuable insights for optimization. By analyzing trends and identifying any deviations from the expected performance, engineers can implement targeted maintenance or design modifications to enhance the heat exchanger’s efficiency.

Conclusion

Air-cooled heat exchangers play a pivotal role in numerous industries, and the continuous advancements in fin design, computational fluid dynamics, and material innovations have significantly enhanced their heat transfer capabilities. From wavy and serrated fin geometries to microchannel heat exchangers and graphene-enhanced composites, the industry is witnessing remarkable progress in the quest for more efficient and compact air-cooled heat transfer solutions.

By understanding the importance of fin design, leveraging the power of CFD optimization, and incorporating the latest material advancements, engineers and heat exchanger manufacturers can push the boundaries of air-cooled heat transfer performance. Coupled with effective maintenance strategies and ongoing performance monitoring, the air-cooled heat exchanger technology continues to evolve, meeting the ever-increasing demands of modern industries.

As an expert in this field, I am excited to see the continued innovation and improvements in air-cooled heat exchanger design and applications. By embracing these advancements, we can drive greater energy efficiency, reduce environmental impact, and push the boundaries of what is possible in thermal engineering.