The Importance of Optimizing Air-Cooled Heat Exchangers

Air-cooled heat exchangers (ACHEs) play a vital role in various industrial processes, from petrochemical refineries and gas processing plants to power generation facilities and HVAC systems. These versatile heat transfer devices utilize the surrounding air to cool or condense process fluids, making them an essential component in maintaining the efficiency and reliability of many critical operations.

As energy consumption and environmental impact become increasingly pressing concerns, optimizing the efficiency of air-cooled heat exchangers has become a top priority for industrial operators. By employing advanced design techniques, innovative fin configurations, and rigorous performance analysis, it is possible to significantly enhance the energy efficiency of these heat exchangers without compromising their reliability or operational capabilities.

In this comprehensive article, we will explore the nuances of air-cooled heat exchanger design, delve into the latest advancements in finned tube optimization, and provide actionable insights to help you maximize the energy efficiency of your ACHE systems.

Understanding the Anatomy of Air-Cooled Heat Exchangers

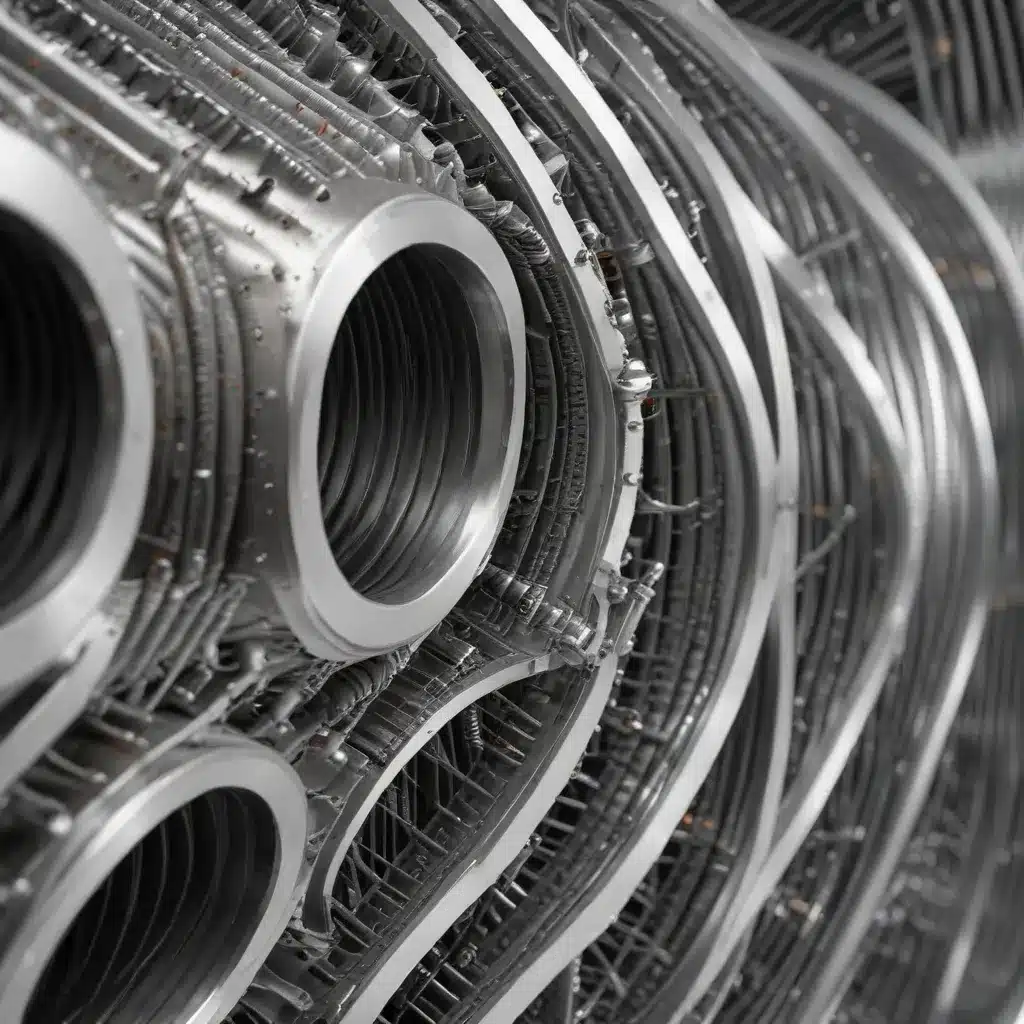

At the heart of an air-cooled heat exchanger is a series of finned tubes, through which the hot process fluid flows. As the fluid passes through the tubes, heat is transferred to the surrounding air, which is directed over the exterior of the tubes by a fan or natural convection.

The design and configuration of these finned tubes play a crucial role in the overall efficiency and performance of the ACHE. Three common fin types are used in air-cooled heat exchangers:

-

L-Fins: Formed by wrapping a metal strip around the base tube, creating an ‘L’ shape. L-fins are a cost-effective solution but are limited in their temperature range and susceptibility to damage in harsher environments.

-

Embedded Fins: The fin material is wound into a helical groove cut into the outer surface of the tube, providing excellent heat transfer and higher temperature capabilities.

-

Extruded Fins: Produced by forcing both the tube and fin material through a die in a single step, creating a strong, integral bond. Extruded fins offer superior corrosion resistance and durability, making them ideal for harsh operating conditions.

The choice of fin type depends on factors such as the operating environment, required heat transfer efficiency, cost considerations, and maintenance practices. Understanding the strengths and limitations of each fin design is crucial in selecting the optimal configuration for a given application.

Optimizing Air Flow and Fan Performance

Achieving efficient air flow over the finned tube bundle is essential for maximizing the heat transfer capabilities of an air-cooled heat exchanger. Three common air flow configurations are used in ACHE systems:

- Forced Draft: Fans are positioned below the tube bundle, pushing air upwards through the heat exchanger.

- Induced Draft: Fans are located above the tube bundle, pulling air through the exchanger and discharging the hot air.

- Natural Draft: Relying on natural convection without the use of fans, this configuration is suitable for large-scale installations where noise reduction is critical.

Each configuration offers unique advantages and trade-offs in terms of maintenance access, air inlet temperatures, and susceptibility to air recirculation. Careful selection and optimization of the air flow system can have a significant impact on the overall efficiency and performance of the ACHE.

In addition to the air flow configuration, the selection and operation of the fans themselves play a crucial role in energy efficiency. Utilizing larger-diameter fans that operate at lower speeds can significantly reduce noise output without compromising cooling performance. Incorporating variable frequency drives (VFDs) allows for precise fan speed control, enabling the system to adapt to changing cooling demands and minimize energy consumption.

Advancements in Finned Tube Design and Optimization

One of the most impactful areas for improving the energy efficiency of air-cooled heat exchangers is the optimization of finned tube design. Advanced computational techniques, such as Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), have revolutionized the way engineers approach finned tube optimization.

Computational Fluid Dynamics (CFD): CFD simulations provide a detailed understanding of fluid flow and heat transfer within the ACHE. By modeling the complex geometries and flow patterns inside the finned tube bundle, engineers can identify areas of flow maldistribution, hot spots, and opportunities for performance enhancement. This information is invaluable in optimizing fin spacing, tube arrangement, and other design parameters to maximize heat transfer and minimize pressure drop.

Finite Element Analysis (FEA): FEA is used to assess the structural integrity and thermal performance of the heat exchanger components, including the tubes, tubesheets, and shell. By applying realistic operating conditions, such as pressure, temperature, and thermal expansion, FEA helps identify potential failure points, optimize material usage, and ensure compliance with safety standards. This analysis is crucial for ensuring the long-term reliability and durability of the ACHE.

In addition to these computational tools, specialized software packages like HTRI Xist and HTRI XACE have been developed specifically for the thermal and hydraulic analysis of shell-and-tube and air-cooled heat exchangers, respectively. These software suites incorporate extensive empirical data and advanced algorithms to predict key performance metrics, allowing engineers to optimize designs for maximum efficiency, safety, and compliance with industry standards.

Maintaining Optimal ACHE Performance Through Proactive Maintenance

Proper maintenance and care are essential for maintaining the energy efficiency and reliability of air-cooled heat exchangers over their lifespan. Regular inspections and preventive measures can help mitigate common issues that can impact ACHE performance, such as:

-

Fouling: Both internal and external fouling can occur, reducing heat transfer efficiency. Implementing effective cleaning methods and anti-fouling coatings is crucial for maintaining optimal performance.

-

Leaks: Identifying and repairing leaks in the header plugs and other components is necessary to prevent further deterioration and ensure efficient heat transfer.

-

Mechanical Wear: Routine maintenance and lubrication of fans, bearings, and other moving parts is essential for ensuring the long-term reliability of the ACHE system.

-

Louver and Actuator Functionality: Inspecting and maintaining the proper operation of louvers, linkages, and actuators is important for managing airflow and optimizing cooling capabilities.

By addressing these maintenance needs proactively, industrial operators can extend the lifespan of their air-cooled heat exchangers, minimize energy consumption, and avoid costly unplanned downtime.

Applying Advanced ACHE Design and Optimization in Industrial Applications

Air-cooled heat exchangers play a critical role in a wide range of industrial sectors, including:

- Carbon Capture: ACHEs are used to cool compressed CO2 streams after compression and before transmission or storage.

- Gas Transmission: Interstage coolers employ ACHEs to cool natural gas at compressor stations, where compression generates significant heat.

- Petrochemical: ACHEs are utilized to condense vapors and cool process streams in various petrochemical operations.

- SAGD and Refining: These industries rely on air-cooled heat exchangers to maintain the temperature of processed fluids and for utility (glycol, water, or steam) cooling.

By leveraging advanced design techniques, innovative fin configurations, and sophisticated computational analysis, industrial operators can optimize the energy efficiency of their air-cooled heat exchangers, leading to reduced energy consumption, lower operating costs, and a more sustainable environmental footprint.

Conclusion: Embracing Cutting-Edge ACHE Design and Optimization

As the demand for energy-efficient and environmentally responsible industrial processes continues to grow, the optimization of air-cooled heat exchangers has become increasingly critical. By embracing advanced computational tools, innovative fin designs, and proactive maintenance practices, industrial operators can unlock the full potential of their ACHE systems, enhancing energy efficiency, improving reliability, and driving sustainable operations.

Whether you are designing a new air-cooled heat exchanger or seeking to upgrade an existing system, the insights and techniques outlined in this article can serve as a valuable guide in your journey towards optimized ACHE performance. By partnering with experienced ACHE experts, you can leverage the latest advancements in finned tube design, air flow optimization, and computational analysis to transform the way you approach thermal management in your industrial operations.

To learn more about how https://www.aircooledheatexchangers.net/ can assist you in enhancing the energy efficiency of your air-cooled heat exchangers, contact us today. Our team of seasoned experts is ready to help you unlock the full potential of this critical heat transfer technology.