As a seasoned expert in the field of air-cooled heat exchangers, I’m excited to share insights on how advancements in fin and tube geometries can significantly enhance the energy efficiency of these critical heat transfer devices. In today’s climate of rising energy costs and sustainability concerns, optimizing the performance of air-cooled heat exchangers has become more crucial than ever.

Importance of Fin and Tube Design in Air-Cooled Heat Exchangers

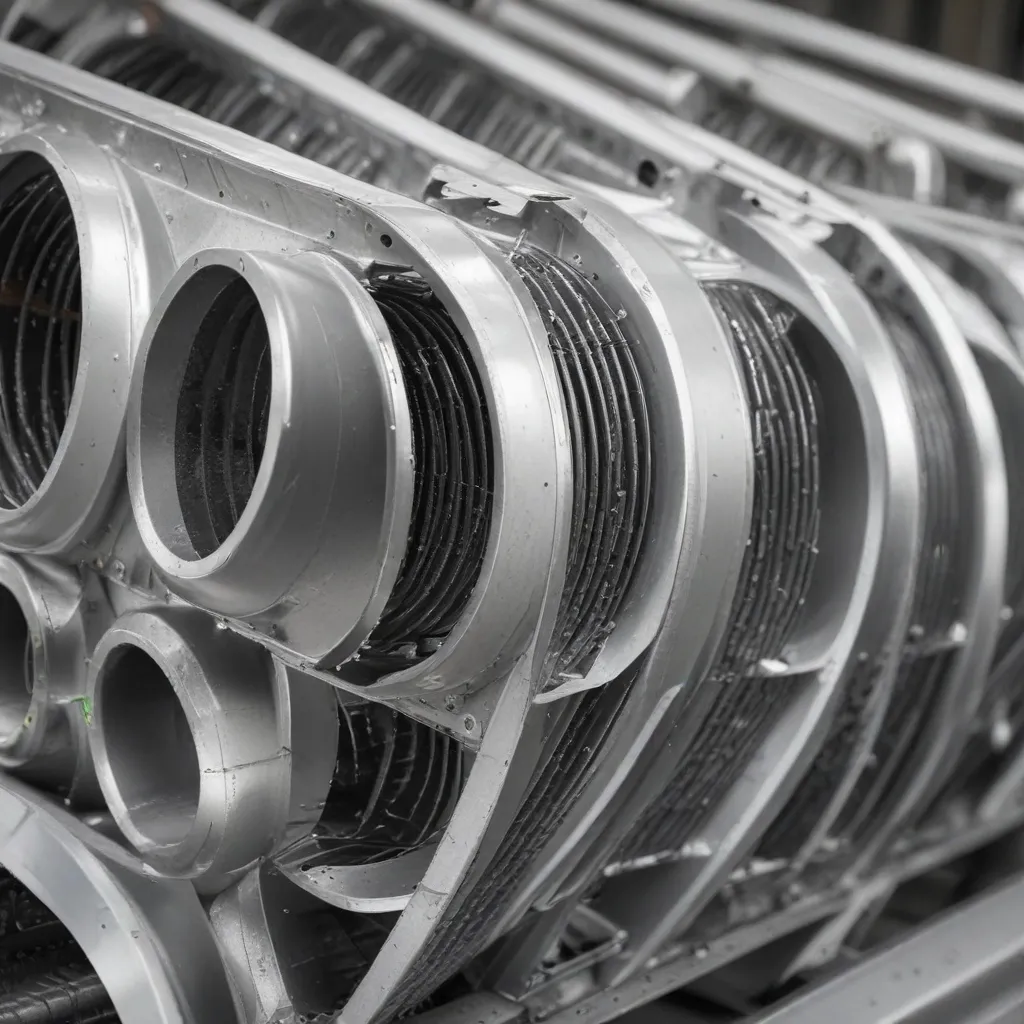

Air-cooled heat exchangers are widely used across various industries, from power generation and petrochemical processing to HVAC systems and industrial refrigeration. These heat exchangers rely on the circulation of ambient air to remove heat from a process fluid, making them an energy-efficient alternative to water-cooled systems in many applications.

The fin and tube geometry plays a pivotal role in determining the overall thermal and hydraulic performance of an air-cooled heat exchanger. The fin design influences the heat transfer coefficient on the air-side, while the tube configuration impacts both the heat transfer and pressure drop characteristics on the fluid side. Optimizing these geometric parameters is crucial for maximizing the energy efficiency and reducing the operating costs of air-cooled heat exchangers.

Enhancing Air-Side Heat Transfer with Advanced Fin Geometries

One of the key areas for improving the energy efficiency of air-cooled heat exchangers is the air-side heat transfer enhancement. Conventional fin designs, such as plate-fin and spiral-fin, have their limitations in terms of heat transfer performance and pressure drop characteristics.

Advanced fin geometries, such as louver fins and herringbone fins, have demonstrated superior air-side heat transfer coefficients compared to traditional designs. These fin types create intricate flow patterns and increased surface area, resulting in enhanced convective heat transfer without a significant increase in pressure drop.

Louver Fins:

Louver fins feature a series of small, closely-spaced, parallel fins that are angled to the airflow direction. The louvers disrupt the boundary layer, promoting turbulence and increasing the effective heat transfer area. Studies have shown that louver fins can achieve up to 30% higher air-side heat transfer coefficients compared to conventional plain fins.

Herringbone Fins:

Herringbone fins, also known as wavy fins, have a wave-like pattern that creates a tortuous flow path for the air. This design induces secondary flow vortices, further enhancing the heat transfer process. Herringbone fins have been reported to yield up to 25% higher air-side heat transfer coefficients than plain fins.

The adoption of these advanced fin geometries can significantly improve the overall thermal performance of air-cooled heat exchangers, leading to reduced energy consumption and operating costs.

Optimizing Fluid-Side Heat Transfer with Innovative Tube Configurations

While the air-side heat transfer is crucial, the fluid-side performance also plays a vital role in the overall efficiency of air-cooled heat exchangers. Innovative tube configurations can help optimize the heat transfer and pressure drop characteristics on the fluid side, further enhancing the energy efficiency of the system.

Internally Enhanced Tubes:

Internally enhanced tubes, such as those with spiral ridges or dimpled surfaces, have been shown to significantly improve the fluid-side heat transfer coefficient. These surface modifications disrupt the boundary layer and create secondary flow patterns, leading to enhanced convective heat transfer. Studies have reported up to 50% improvement in the fluid-side heat transfer coefficient with the use of internally enhanced tubes.

Finned Tubes:

The incorporation of fins on the tube exterior can also contribute to improved fluid-side performance. Finned tubes increase the effective heat transfer surface area, leading to higher overall heat transfer rates. Additionally, the fin design can be tailored to optimize the air-side heat transfer, creating a synergistic effect on the overall exchanger performance.

Tube Bundles with Optimized Arrangements:

The arrangement and spacing of tube bundles within an air-cooled heat exchanger can also impact the fluid-side and air-side performance. Carefully designed tube bundle configurations, such as staggered or inline arrangements, can help minimize pressure drop and enhance heat transfer, ultimately improving the energy efficiency of the system.

By combining advanced fin geometries with innovative tube configurations, air-cooled heat exchanger designers can achieve significant improvements in overall thermal and hydraulic performance, resulting in substantial energy savings and reduced operating costs.

Maintenance and Operational Considerations for Optimal Performance

Maintaining the optimal performance of air-cooled heat exchangers is essential for maintaining their energy efficiency over time. Regular maintenance and monitoring of key parameters can help identify and mitigate potential issues that may arise, such as fouling, corrosion, or airflow blockages.

Fouling and Cleaning Strategies:

Fouling on the air-side and fluid-side surfaces can significantly degrade the heat transfer performance of air-cooled heat exchangers over time. Implementing effective cleaning strategies, such as regular chemical or mechanical cleaning, can help maintain the heat transfer efficiency and minimize the energy consumption of the system.

Corrosion and Material Selection:

The choice of materials for the fin and tube components is crucial in ensuring the long-term reliability and performance of air-cooled heat exchangers. Corrosion-resistant materials, such as stainless steel or copper alloys, can help prevent deterioration and maintain the design heat transfer characteristics.

Airflow Management and Fan Performance:

Ensuring efficient airflow through the heat exchanger is essential for optimizing its energy performance. Regularly inspecting and maintaining the fan systems, as well as addressing any obstructions or blockages in the air inlet and outlet, can help maintain the design airflow and maximize the heat transfer capabilities.

By adopting a proactive approach to maintenance and operational optimization, air-cooled heat exchanger operators can further enhance the energy efficiency and sustainability of their systems, reaping the benefits of improved performance and reduced energy consumption.

Conclusion

In the pursuit of energy efficiency and sustainability, advancements in fin and tube geometries have emerged as a powerful tool for enhancing the performance of air-cooled heat exchangers. By leveraging innovative designs, such as louver fins, herringbone fins, and internally enhanced tubes, air-cooled heat exchanger engineers can significantly improve both air-side and fluid-side heat transfer, leading to substantial energy savings and reduced operating costs.

Complementing these technological advancements, a comprehensive approach to maintenance and operational optimization is crucial for maintaining the long-term energy efficiency of air-cooled heat exchangers. By addressing fouling, corrosion, and airflow management, operators can ensure that their systems continue to operate at peak performance, contributing to the broader goals of sustainable energy systems.

As the demand for energy-efficient and environmentally-friendly industrial processes continues to grow, the strategic application of advanced fin and tube geometries in air-cooled heat exchangers will play a pivotal role in driving progress towards a more sustainable future. By embracing these cutting-edge technologies and best practices, air-cooled heat exchanger experts can contribute to the collective effort of enhancing energy efficiency and reducing the environmental impact of industrial operations.

To learn more about the latest advancements in air-cooled heat exchanger design and optimization, I encourage you to explore the resources available on the Air Cooled Heat Exchangers website. Our team of industry experts is dedicated to providing practical insights and innovative solutions to help you achieve your energy efficiency and sustainability goals.