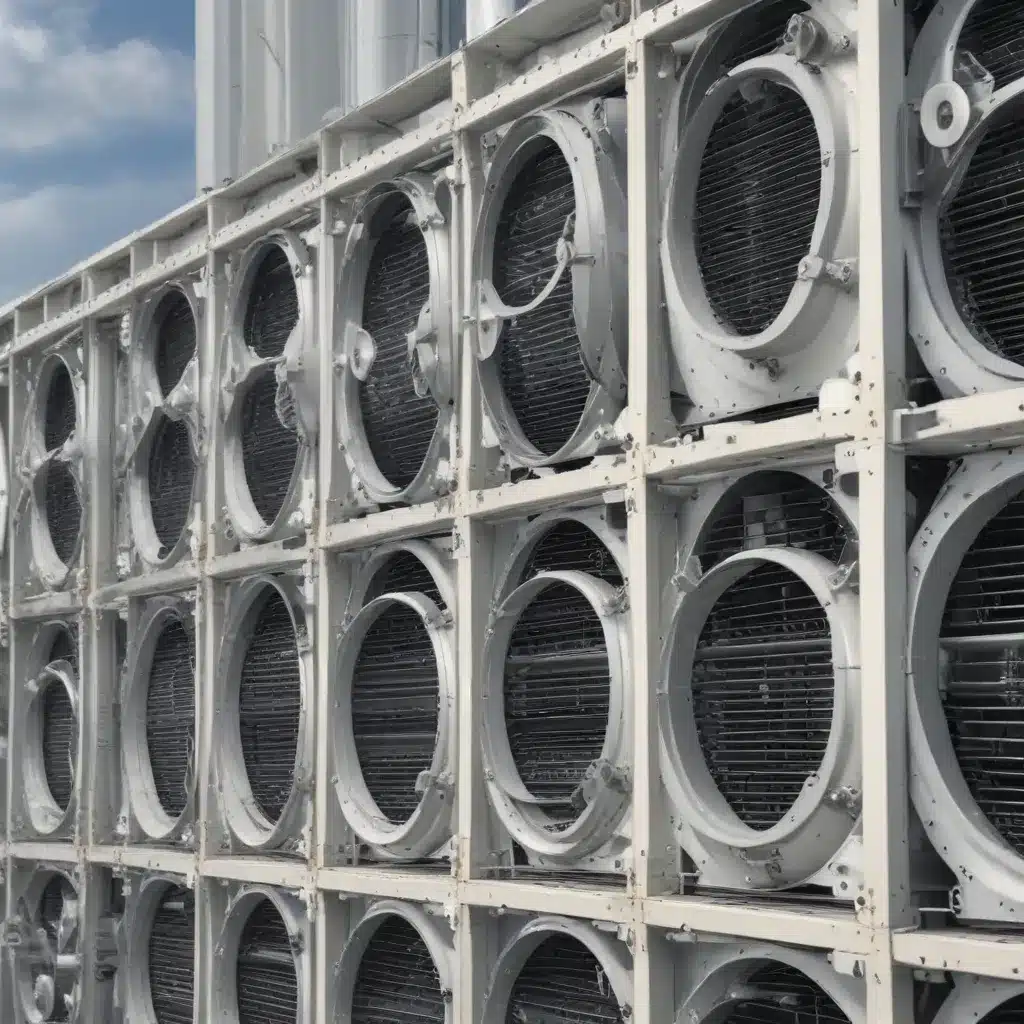

Harnessing the Power of Air-Cooled Heat Exchangers for Industrial Cooling

In the bustling world of industrial operations, the quest for efficiency is never-ending. Air Cooled Heat Exchangers (ACHEs) have become a pivotal component in the pursuit of enhanced energy savings, process optimization, and environmental responsibility. As seasoned experts in this field, we’ll delve into the intricate world of ACHEs, exploring practical tips and in-depth insights to help you unlock their full potential.

Understanding the Mechanics of Heat Transfer

At the heart of an ACHE lies the fundamental process of heat transfer. This process involves the movement of thermal energy from a hotter medium to a cooler one, facilitated by three primary mechanisms:

- Conduction: The transfer of heat through direct contact between molecules, allowing energy to flow from areas of higher temperature to areas of lower temperature.

- Convection: The transfer of heat by the movement of a fluid, such as air or water, across a surface. This can be either natural (driven by buoyancy) or forced (using fans or pumps).

- Radiation: The emission of electromagnetic waves, which can transport heat without the need for a physical medium.

By understanding these mechanisms and how they interplay within an ACHE, designers and engineers can optimize the system’s performance, enhancing energy efficiency and cooling effectiveness.

Types of Air-Cooled Heat Exchangers

Air-cooled heat exchangers come in various configurations, each with its own advantages and applications. Some of the most common types include:

- Finned Tube Heat Exchangers: These feature a series of tubes with attached fins, which increase the surface area for efficient heat transfer between the fluid flowing inside the tubes and the air passing over the fins.

- Plate-Fin Heat Exchangers: Consisting of flat plates with corrugated fins, these exchangers provide excellent heat transfer performance in a compact design, making them suitable for applications with space constraints.

- Cross-Flow Heat Exchangers: In this design, the hot and cold fluids flow perpendicular to each other, maximizing the surface area for heat exchange and enabling efficient cooling.

- Compact Heat Exchangers: These highly efficient exchangers employ advanced geometries, such as micro-channels or offset strip fins, to achieve high heat transfer rates in a small footprint.

The selection of the appropriate ACHE type depends on factors such as the specific cooling requirements, available space, operating conditions, and budget considerations. By carefully matching the heat exchanger design to the application, industries can optimize energy efficiency and performance.

Industrial Applications of Air-Cooled Heat Exchangers

Air-cooled heat exchangers find widespread use across a diverse range of industries, each with its unique cooling needs and challenges. Some notable applications include:

- Power Generation: ACHEs play a crucial role in power plants, dissipating the waste heat generated by turbines, generators, and other equipment, ensuring efficient and reliable energy production.

- Petrochemical and Refining: In these industries, ACHEs are essential for cooling process streams, lubricating oils, and other fluids, contributing to the safety and efficiency of operations.

- Manufacturing: From electronics and automotive to pharmaceuticals and food processing, ACHEs help maintain optimal operating temperatures for machinery, ensuring product quality and process stability.

- Data Centers: As the demand for data processing and storage continues to rise, ACHEs have become indispensable in maintaining the thermal management of servers and other critical IT equipment, enabling energy-efficient operations.

- HVAC Systems: ACHEs are a vital component in heating, ventilation, and air conditioning (HVAC) systems, providing efficient cooling for both commercial and residential applications.

By carefully selecting and integrating ACHEs into these diverse industrial settings, organizations can unlock significant energy savings, improve process reliability, and reduce their environmental impact.

Benefits of Efficient Air-Cooled Heat Exchangers

The advantages of incorporating high-performance ACHEs into industrial cooling systems are numerous and profound. Some of the key benefits include:

- Energy Savings: By optimizing heat transfer and reducing the energy required for cooling, efficient ACHEs can lead to substantial reductions in electricity consumption and operating costs.

- Improved Reliability: Effective thermal management helps prevent equipment overheating, reducing the risk of breakdowns and prolonging the lifespan of critical industrial assets.

- Enhanced Productivity: Maintaining optimal operating temperatures ensures consistent and reliable production, minimizing downtime and maximizing output.

- Environmental Responsibility: The improved energy efficiency of ACHEs translates to a lower carbon footprint, contributing to a more sustainable industrial landscape.

- Flexible Design: ACHEs can be customized to meet the specific cooling requirements of various applications, offering versatility and adaptability.

By leveraging these benefits, industries can gain a competitive edge, enhance their environmental stewardship, and achieve long-term cost savings.

Maintaining and Optimizing Air-Cooled Heat Exchangers

To ensure the longevity and peak performance of ACHEs, it is essential to follow a comprehensive maintenance regimen. Some key best practices include:

- Regular Cleaning: Periodically cleaning the fins, tubes, and other components to remove accumulated dirt, dust, and debris, which can impede airflow and reduce heat transfer efficiency.

- Inspection and Monitoring: Regularly inspecting the ACHE for signs of wear, corrosion, or fouling, and addressing any issues promptly to prevent further deterioration.

- Optimizing Airflow: Ensuring that the airflow around the ACHE is unobstructed and that the fan(s) are operating at the optimal speed and efficiency.

- Proactive Maintenance: Implementing a preventive maintenance program, including scheduled inspections, lubricating moving parts, and replacing worn components before they fail.

- Performance Optimization: Continuously monitoring the ACHE’s performance and making adjustments to operating parameters, such as fan speed or coolant flow rate, to maximize efficiency.

By adhering to these best practices, industries can extend the lifespan of their ACHEs, minimize maintenance costs, and maintain peak cooling performance throughout the equipment’s lifetime.

Future Trends and Innovations in Air-Cooled Heat Exchangers

The field of ACHE technology is continuously evolving, driven by the growing demand for more efficient and sustainable industrial cooling solutions. Some emerging trends and innovations to watch include:

- Advancements in Materials and Coatings: The development of new materials and coatings for ACHE components, such as corrosion-resistant and self-cleaning surfaces, can enhance durability and improve heat transfer performance.

- Intelligent Controls and Automation: The integration of smart sensors, advanced algorithms, and automated control systems can optimize ACHE operation, adapting to changing conditions and maximizing energy efficiency.

- Hybrid Cooling Systems: The combination of air-cooled and liquid-cooled heat exchangers, known as hybrid cooling, can provide the benefits of both technologies, offering enhanced overall system efficiency.

- Waste Heat Recovery: Innovative ACHE designs that can capture and repurpose waste heat, such as through the use of thermoelectric generators, can further improve the overall energy efficiency of industrial processes.

- Sustainability and Environmental Considerations: As the focus on sustainability and environmental responsibility intensifies, ACHEs are being designed with reduced water consumption, lower noise levels, and improved energy efficiency to minimize the ecological impact of industrial operations.

By staying informed about these emerging trends and innovations, industries can strategically invest in cutting-edge ACHE technologies, positioning themselves for long-term success and environmental stewardship.

Conclusion: Embracing the Future of Air-Cooled Heat Exchangers

In the heart of industrial facilities, cooling systems play a critical role in ensuring efficiency and productivity. Among these systems, air-cooled heat exchangers have become indispensable, providing reliable and energy-efficient thermal management solutions across a diverse range of industries.

By understanding the principles of heat transfer, selecting the appropriate ACHE design, and following best practices for maintenance and optimization, industries can unlock the full potential of these versatile components. As the landscape of ACHE technology continues to evolve, embracing innovative and sustainable solutions will be key to maintaining a competitive edge and driving progress towards a more energy-efficient future.

To explore the possibilities of air-cooled heat exchangers in your operations, visit our website and discover how we can help you enhance energy efficiency and unlock new levels of performance.