Unveiling the Potential of Innovative Fin Designs and Functionalized Surfaces

Air-cooled heat exchangers play a critical role in various industries, from automotive and aerospace to chemical processing and power generation. As technology advances and systems become more compact and energy-dense, the demand for improved thermal management solutions has never been greater. In this comprehensive article, we will delve into the latest advancements in air-cooled heat exchanger design, exploring how novel fin geometries and specialized surface coatings can unlock unprecedented levels of performance and efficiency.

Overcoming the Limitations of Conventional Fin Designs

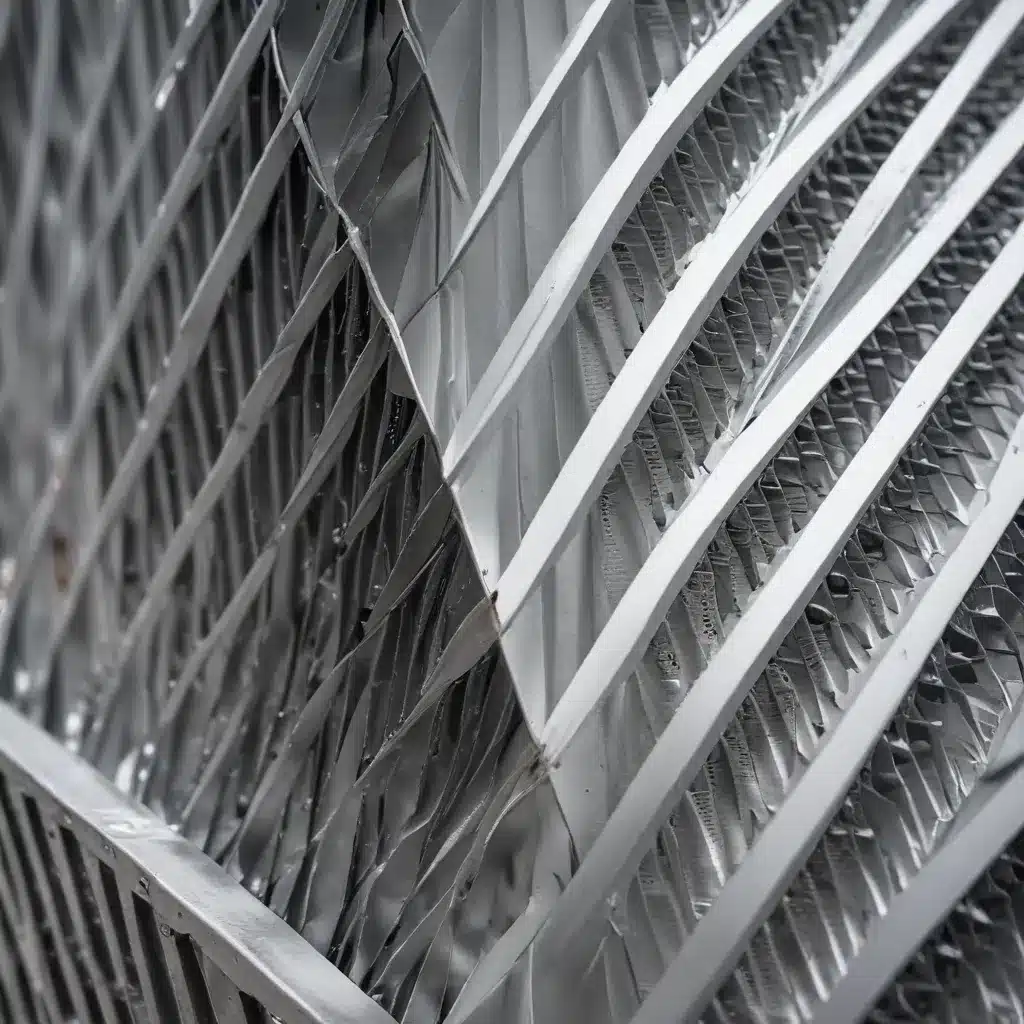

Traditionally, air-cooled heat exchangers have relied on simple geometric fin configurations, such as straight, circular, or triangular fins. While these designs have proven effective, they often struggle to keep pace with the rapidly evolving thermal management requirements of modern applications. The research presented in this article highlights the potential of more advanced fin geometries to significantly enhance heat transfer and reduce pressure drop.

One of the promising approaches explored in recent studies is the incorporation of cross-shaped, I-shaped, and V-shaped pin fins. These novel fin configurations have demonstrated the ability to increase the surface area in contact with the phase change material (PCM), leading to improved heat transfer and a remarkable reduction in the device’s base plate temperature. The researchers found that the V-shaped fin geometry, in particular, could decrease the maximum base plate temperature by up to 6.6% compared to the more conventional circular fin design.

The key to the enhanced performance of these innovative fin geometries lies in their ability to optimize the heat transfer and fluid flow characteristics within the air-cooled heat exchanger. The unique shapes and orientations of the cross-shaped, I-shaped, and V-shaped fins create intricate flow patterns and increased turbulence, which can significantly enhance the convective heat transfer coefficient. Additionally, the greater surface area in contact with the PCM allows for more efficient latent heat storage and release, further improving the overall thermal management capabilities of the system.

Leveraging Surface Coatings for Thermal Performance Optimization

While advancements in fin geometry have shown promising results, the potential of air-cooled heat exchangers can be further unlocked through the strategic application of specialized surface coatings. Recent studies have explored the use of nanostructured coatings to modify the wettability and fluid-surface interactions within heat exchangers, leading to remarkable improvements in thermal and pressure drop performance.

The development of superhydrophobic and oleophobic coatings has been a particular area of interest. These functionalized surfaces, characterized by high water and oil contact angles, can significantly reduce the frictional forces between the fluid and the heat exchanger’s internal surfaces. This phenomenon, known as the “slip effect,” can lead to a decrease in pressure drop across the heat exchanger, ultimately enhancing its efficiency and reducing the energy required for fluid circulation.

Moreover, the nanostructured coatings can also influence the heat transfer mechanisms by altering the boundary layer dynamics and promoting the formation of favorable flow patterns. Studies have reported that the application of these coatings can increase the overall heat transfer coefficient by up to 50% compared to uncoated heat exchangers.

The integration of novel fin geometries and functionalized surface coatings presents a powerful synergy, as the combined effects can lead to even greater performance improvements. By optimizing both the fin design and the surface characteristics, air-cooled heat exchangers can achieve remarkable advancements in heat transfer, pressure drop, and overall thermal management capabilities.

Practical Considerations and Real-World Applications

Implementing these innovative solutions in real-world air-cooled heat exchanger applications requires careful consideration of various factors, such as manufacturing feasibility, durability, and compatibility with existing systems.

The researchers highlight the importance of developing coating deposition techniques that can be seamlessly integrated into the current production processes, such as brazing or bonding, without compromising the integrity of the nanostructured layers. Careful optimization of the coating application methods and post-treatment processes is crucial to ensure long-term performance and reliability.

Moreover, the assessment of the coatings’ resistance to environmental factors, such as temperature, humidity, and corrosive agents, is vital to ensure the heat exchangers can withstand the rigors of real-world operating conditions. The studies have revealed that the durability of the nanostructured coatings is a critical factor, as exposure to harsh environments can lead to the degradation of the superhydrophobic and oleophobic properties over time.

Despite these challenges, the potential benefits of leveraging novel fin geometries and functionalized surface coatings in air-cooled heat exchangers are immense. By continuously pushing the boundaries of thermal management technology, engineers and researchers can develop next-generation heat exchangers that are more compact, efficient, and capable of meeting the ever-increasing demands of modern industries.

Unlocking the Future of Air-Cooled Heat Exchanger Performance

As the world continues to seek more sustainable and energy-efficient solutions, the advancements in air-cooled heat exchanger design and surface engineering hold tremendous promise. By combining innovative fin geometries and advanced surface coatings, engineers can create heat exchangers that deliver superior thermal performance, reduced pressure drop, and enhanced reliability.

The insights and findings presented in this article highlight the exciting potential of these cutting-edge technologies. As researchers and industry professionals continue to explore and refine these approaches, we can expect to see even more remarkable improvements in the thermal management capabilities of air-cooled heat exchangers across a wide range of applications.

To stay informed about the latest developments in this field, be sure to visit the Air Cooled Heat Exchangers blog for more informative articles and expert insights. By embracing these innovative solutions, we can unlock a future where air-cooled heat exchangers play an even more pivotal role in driving technological advancements and sustainable progress.