The promise of nanofluids in thermal management

As technology and energy products require higher standards of function and performance, the problem of heat dissipation is becoming a significant issue in many appliances. Using a working fluid with high heat transfer performance is a topic worthy of research, as it may solve this problem without costly changes in the structure of the equipment. Many researchers have recently investigated the issue of nanofluid thermal properties, and the results show that nanofluids can enhance heat conduction performance due to their higher thermal conductivity than base fluids.

However, heat convection characteristics must also be considered in practical heat exchange applications. Numerous studies have focused on the heat transfer properties of convection for a single pipe with different structures, investigating parameters such as nanoparticle type and concentration, pipe cross-section, materials, flow conditions, and other factors. These studies have demonstrated that nanofluids can enhance the heat transfer performance in various heat exchange systems, including electronic liquid cooling, microchannel heat sinks, plate heat exchangers, double-tube heat exchangers, and heated enclosures.

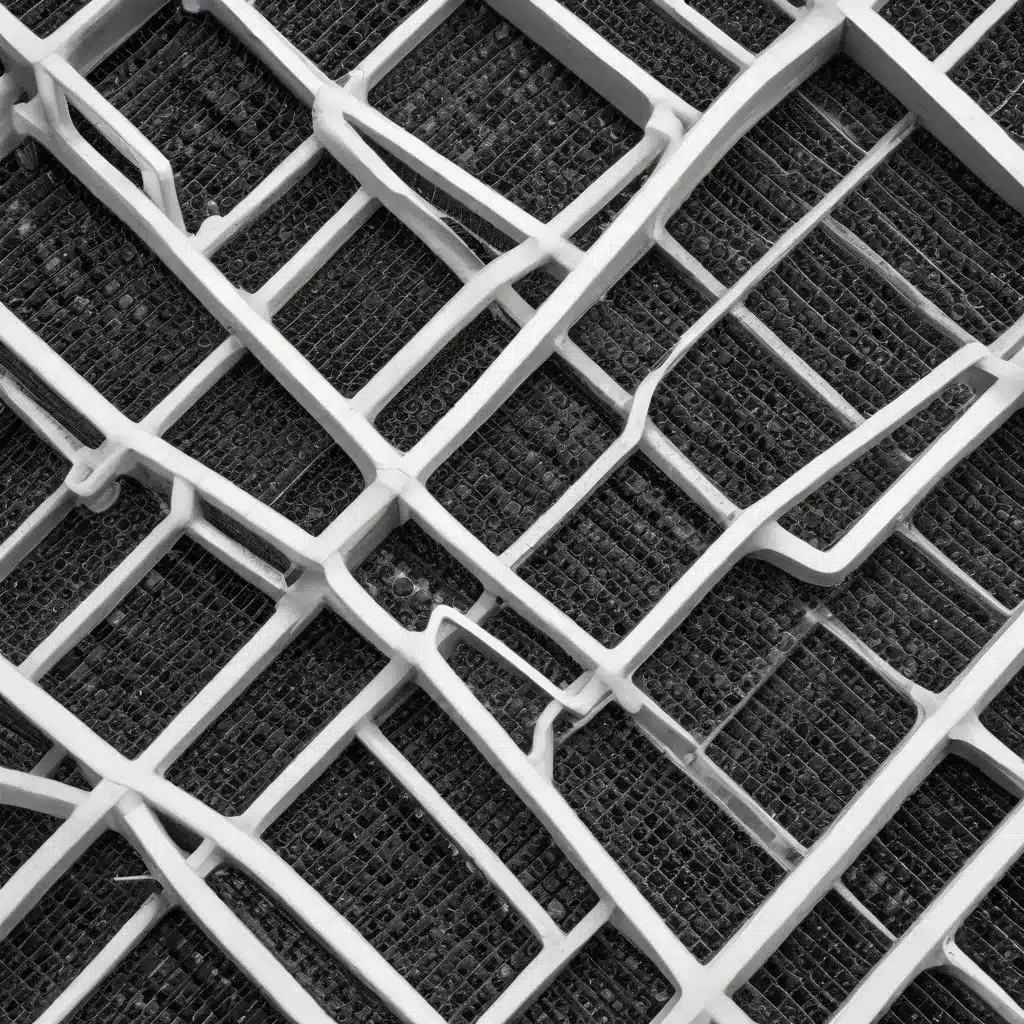

Despite the promising results, nanofluids have been seldom used in air-cooled heat exchangers, which are widely employed in automotive, air conditioning, proton exchange membrane fuel cell (PEMFC), and electronic chip cooling applications. Since the ultimate goal of radiators is to discharge heat into the atmosphere, air-cooled heat exchangers are a worthy research direction for exploring the potential of nanofluids in thermal management.

Evaluating the performance of Al2O3/water nanofluids in air-cooled heat exchangers

This study analyzes the characteristics of alumina (Al2O3)/water nanofluid to determine the feasibility of its application in an air-cooled heat exchanger for heat dissipation in PEMFC or electronic chip cooling. The experiments in this study measured the thermal conductivity and viscosity of the nanofluid at different concentrations (0.5, 1.0, and 1.5 wt.%) and temperatures (20-60°C), and then used the nanofluid in an actual air-cooled heat exchanger to assess its heat exchange capacity and pressure drop under laminar flow.

Experimental results show that the nanofluid has a higher heat exchange capacity than water, and a higher concentration of nanoparticles provides an even better ratio of heat exchange. The maximum enhanced ratio of heat exchange and pressure drop for all the experimental parameters in this study was about 39% and 5.6%, respectively. In addition to nanoparticle concentration, the temperature and mass flow rates of the working fluid can also affect the enhanced ratio of heat exchange and pressure drop of the nanofluid.

Preparing the Al2O3/water nanofluid

The base liquid was prepared by adding 0.2 wt.% of cationic dispersant (water-soluble chitosan) to distilled water to obtain good suspension for the nanofluid. The Al2O3/water nanofluid produced by a two-step synthesis method was then used as the experimental sample, with homogenization, electromagnetic agitation, and ultrasonic vibration alternately used to disperse the Al2O3 nanoparticles into three weight fractions (0.5, 1.0, and 1.5 wt.%).

The reason for using a lower concentration of nanofluid was to avoid blocking pipes and an overly high pressure drop caused by the sedimentation of nanoparticles and increased viscosity from a high concentration of nanofluid. The Al2O3 nanoparticles used in this study have a real density of approximately 3,880 kg/m³, which can be converted to weight fraction and volume fraction using the appropriate equations.

Characterizing the nanofluid properties

The thermal conductivity and viscosity of the nanofluid were measured at various temperatures and concentrations using a thermal properties analyzer and a rheometer, respectively. The results showed that as the temperature increases, the effect of increasing nanoparticle concentration on the thermal conductivity ratio is lower than changing the applied temperature. Increasing both the concentration and temperature raises the probability that nanoparticle-liquid collisions will produce a near quasi-convection phenomenon, helping to increase the thermal conductivity of the Al2O3/water nanofluid.

However, the viscosity of the nanofluid increases with increasing nanoparticle loading in the base liquid. For a concentration of 0.5 wt.% and within a temperature range of 20°C to 60°C, the viscosity ratio increases by 21.5% to 41.3%. For a concentration of 1.0 wt.%, the viscosity ratio increases by 32.7% to 47.8%, and for a concentration of 1.5 wt.%, the viscosity ratio increases by 38.7% to 56.3%. These results show that the viscosity of the Al2O3/water nanofluid is much higher than water, which must be considered when addressing pressure drop issues in the heat exchanger.

Evaluating heat exchange and pressure drop in the air-cooled heat exchanger

The heat exchange capacity and pressure drop experiments in this study used a heated tank to simulate the heating source, and evaluated the cooling performance of the nanofluid using an air-cooled heat exchanger under different conditions for concentration, temperature, and nanofluid mass flow rate.

The results show that the nanofluid can enhance the air-cooled heat exchange capacity ratio under all experimental conditions investigated in this study. This is primarily because the added nanoparticles improve the heat transfer performance of the fluid through mechanisms such as enhanced thermal conductivity, increased nanoparticle collisions with the base fluid and heat exchanger walls, and improved convective heat transfer.

However, the enhanced ratio of heat exchange decreases at higher temperatures, likely due to the uneven flow rate distribution in the rectangular tube with a high aspect ratio. The higher viscosity of the nanofluid at high temperatures can strengthen this phenomenon, leading to a lower enhanced ratio of heat exchange compared to lower temperatures.

The maximum enhanced ratio of heat exchange was obtained at 30°C and 1.5 wt.% nanofluid concentration, reaching about 33-39% compared to water. The enhanced ratio of pressure drop was also measured, with the largest value being 5.6% at 30°C, 0.035 kg/s mass flow rate, and 1.5 wt.% concentration.

Optimizing air-cooled heat exchanger performance with nanofluids

The experiments on heat exchange and pressure drop show that the overall benefits significantly decrease when the nanofluid is used in the air-cooled heat exchanger at higher temperatures. The enhanced ratio of pressure drop can even become higher than the enhanced ratio of heat exchange under some conditions, leading to a lower overall efficiency of the cooling system using the nanofluid compared to water.

Therefore, the air-cooled heat exchanger operating at 30-40°C has the best overall efficiency in this study. At these temperatures, the nanofluid provides a maximum enhanced ratio of heat exchange of about 33-39% without an overly high pressure drop. Considering both the heat exchange performance and pump power consumption, the 0.05 wt.% Al2O3/water nanofluid exhibited the best overall system performance.

As technology continues to advance, the need for effective thermal management solutions will only grow. The results of this study demonstrate the potential of nanofluids, such as Al2O3/water, to enhance the performance of air-cooled heat exchangers without requiring major structural changes to the equipment. By carefully optimizing the nanofluid concentration, temperature, and flow rate, engineers can unlock the benefits of nanofluids in a wide range of industrial and consumer applications.

To learn more about the latest developments in air-cooled heat exchanger technology, be sure to visit the Air Cooled Heat Exchangers website. There you’ll find a wealth of expert insights, practical tips, and industry-leading resources to help you stay ahead of the curve.