Unlocking the Potential of Air-Cooled Heat Exchangers

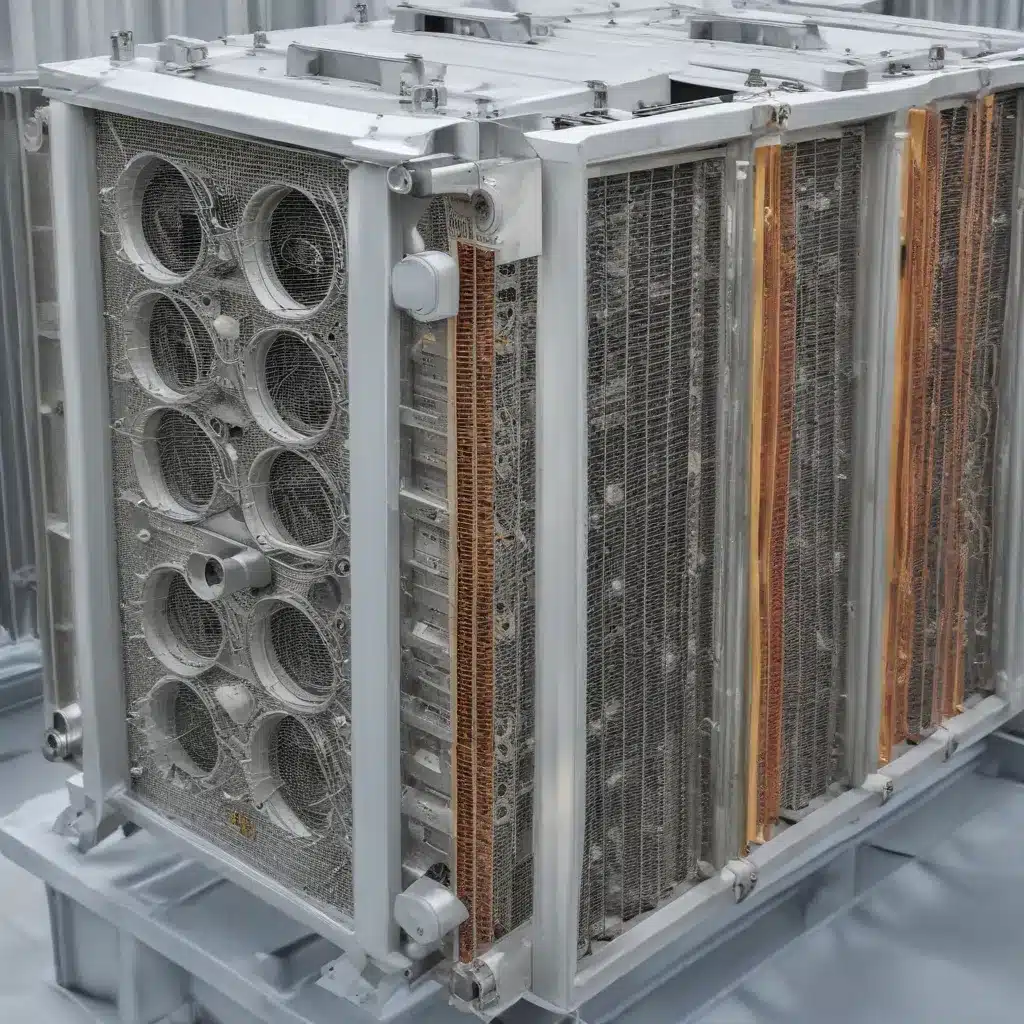

Air-cooled heat exchangers are essential components in a wide range of industrial and commercial applications, from power generation and manufacturing to HVAC systems and refrigeration. As the demand for energy-efficient and environmentally friendly solutions continues to grow, the optimization of air-cooled heat exchanger performance has become a top priority for engineers and researchers. By leveraging the latest advancements in materials science and heat transfer principles, we can unlock new frontiers in air-cooled heat exchanger design and operation.

This comprehensive article delves into the cutting-edge strategies and emerging technologies that are transforming the landscape of air-cooled heat exchangers. From the strategic incorporation of multifunctional materials to the implementation of passive cooling techniques, we will explore practical solutions that can significantly enhance the performance, efficiency, and reliability of these essential heat transfer systems.

Harnessing the Power of Multifunctional Materials

One of the most promising avenues for improving air-cooled heat exchanger performance is the strategic use of multifunctional materials. These advanced materials possess unique properties that can simultaneously address multiple challenges, such as improved heat transfer, reduced fouling, and enhanced corrosion resistance.

Nanostructured Coatings: The integration of nanostructured coatings on heat exchanger surfaces has demonstrated remarkable potential in enhancing heat transfer rates. These coatings, which can be applied through various deposition techniques, feature a high surface area-to-volume ratio and tailored surface topography. This can lead to increased heat transfer coefficients, improved wettability, and reduced fouling propensity, ultimately boosting the overall efficiency of the heat exchanger.

Hybrid Nanomaterial Composites: The incorporation of hybrid nanomaterial composites, such as the combination of carbon nanotubes and graphene, can further optimize air-cooled heat exchanger performance. These advanced materials exhibit superior thermal conductivity, allowing for more efficient heat dissipation. Additionally, their unique surface characteristics can contribute to improved wettability, anti-fouling properties, and enhanced corrosion resistance.

Phase-Change Materials (PCMs): The strategic integration of phase-change materials within air-cooled heat exchangers can significantly enhance their thermal management capabilities. These materials undergo reversible phase transitions, absorbing or releasing latent heat during the process. By strategically positioning PCM-based heat sinks, the temperature fluctuations within the heat exchanger can be dampened, leading to more stable and efficient operation.

Leveraging Passive Cooling Strategies

In parallel with the advancements in multifunctional materials, passive cooling strategies have emerged as powerful tools to optimize air-cooled heat exchanger performance without relying on active energy-consuming systems.

Biomimetic Surfaces: Drawing inspiration from nature, researchers have developed biomimetic surfaces that mimic the intricate structures and functionalities observed in natural systems. These surfaces, often featuring hierarchical micro- and nano-scale patterns, can enhance heat transfer through improved wettability, reduced boundary layer thickness, and the promotion of turbulent flow regimes.

Evaporative Cooling: The incorporation of evaporative cooling techniques, such as the use of porous media or wetted surfaces, can significantly boost the heat dissipation capabilities of air-cooled heat exchangers. As the airflow passes over the wetted surfaces, the evaporative cooling effect can lead to substantial reductions in the air and surface temperatures, resulting in improved overall efficiency.

Finned Structures: The strategic design and optimization of finned structures within air-cooled heat exchangers can dramatically enhance heat transfer performance. Advanced computational fluid dynamics (CFD) modeling and additive manufacturing techniques have enabled the development of highly efficient fin geometries, such as wavy, louvered, or corrugated fins, which can promote turbulent airflow and increase the effective heat transfer area.

Integrating Hybrid Cooling Approaches

While the individual strategies discussed above offer significant improvements, the true potential of air-cooled heat exchanger optimization lies in the synergistic integration of multiple cooling approaches. By combining the strengths of different techniques, engineers can create hybrid cooling systems that deliver unparalleled performance and versatility.

Thermoelectric-Enhanced Cooling: The integration of thermoelectric cooling modules with air-cooled heat exchangers can provide a unique hybrid solution. Thermoelectric devices, which leverage the Peltier effect, can actively pump heat away from the heat exchanger, effectively complementing the passive cooling strategies. This hybrid approach can result in enhanced heat dissipation, improved temperature control, and increased overall system efficiency.

Integrated PCM-Finned Structures: The combination of phase-change materials and advanced finned structures can create a powerful passive cooling system for air-cooled heat exchangers. The PCMs can absorb and release heat during phase transitions, effectively dampening temperature fluctuations, while the finned structures optimize the heat transfer to the surrounding airflow.

Biomimetic Surfaces with Evaporative Cooling: By integrating biomimetic surface structures with evaporative cooling techniques, air-cooled heat exchangers can benefit from the synergistic effects of improved wettability, turbulent flow promotion, and the evaporative cooling phenomenon. This hybrid approach can lead to significant enhancements in heat transfer performance and reduced operational temperatures.

Unlocking the Future: Opportunities and Considerations

As the field of air-cooled heat exchanger design and optimization continues to evolve, several emerging opportunities and considerations come into focus:

-

Additive Manufacturing and Customized Geometries: The rise of additive manufacturing technologies, such as 3D printing, has opened up new avenues for the creation of intricate and customized heat exchanger geometries. This can enable the rapid prototyping and implementation of highly optimized fin structures, tailored to specific applications and operating conditions.

-

Integrated Sensing and Predictive Maintenance: The integration of advanced sensing technologies and predictive analytics can revolutionize the maintenance and operation of air-cooled heat exchangers. By monitoring key parameters, such as fouling levels, vibration, and corrosion, operators can proactively address issues and optimize the overall system performance.

-

Sustainable and Environmentally Friendly Materials: As the emphasis on sustainability and environmental stewardship grows, the development of air-cooled heat exchangers that utilize eco-friendly and recyclable materials will become increasingly important. This includes the use of biodegradable or bio-based materials, as well as the incorporation of circular economy principles in the design and manufacturing processes.

-

Optimization through Computational Modeling: Advancements in computational fluid dynamics (CFD) and multiphysics simulations have enabled more accurate modeling and optimization of air-cooled heat exchanger designs. By leveraging these computational tools, engineers can explore and test a wider range of design alternatives, leading to more efficient and cost-effective solutions.

-

Synergies with Renewable Energy Systems: As the global shift towards renewable energy continues, the integration of air-cooled heat exchangers with solar, wind, or geothermal power systems will become increasingly relevant. Optimizing the thermal management of these renewable energy applications can lead to enhanced overall system efficiency and reliability.

Conclusion

In the pursuit of energy-efficient and sustainable solutions, the optimization of air-cooled heat exchanger performance has become a crucial focus area. By harnessing the power of multifunctional materials and leveraging passive cooling strategies, we can unlock new frontiers in heat transfer technology. The strategic integration of hybrid cooling approaches, such as thermoelectric-enhanced systems and biomimetic surface structures, further amplifies the potential for significant performance improvements.

As the industry continues to evolve, the integration of additive manufacturing, predictive maintenance, sustainable materials, and computational modeling will play a pivotal role in shaping the future of air-cooled heat exchangers. By embracing these advancements, we can create heat transfer systems that are more efficient, reliable, and environmentally responsible, contributing to the broader goal of a sustainable energy future.

Visit https://www.aircooledheatexchangers.net/ to explore more articles and resources on the latest developments in air-cooled heat exchanger technology.