Unlocking the Full Potential of Air-Cooled Heat Exchangers with Intelligent Design and Control

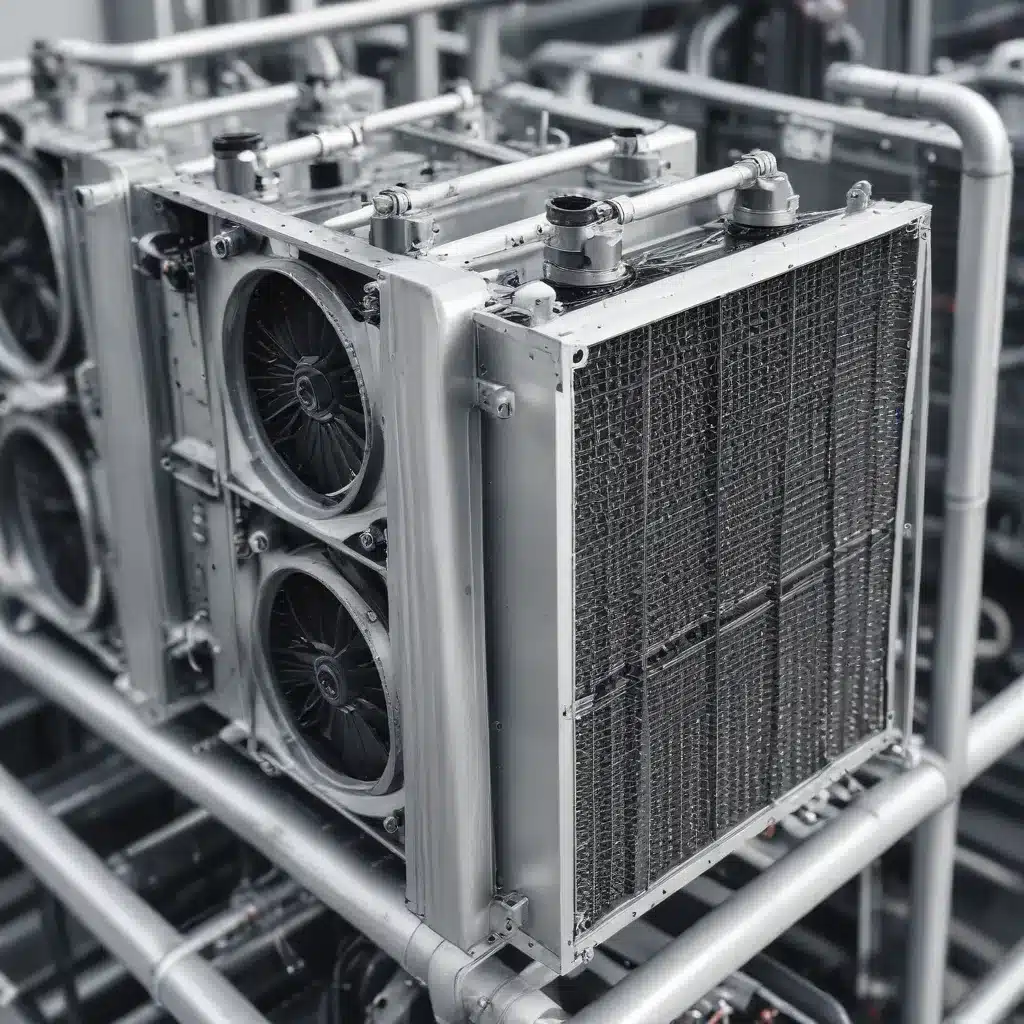

In the ever-evolving landscape of thermal management systems, air-cooled heat exchangers have long been the backbone of various industries, from power generation and HVAC to petrochemical processing and industrial manufacturing. As the demand for energy-efficient and reliable thermal solutions continues to surge, harnessing the full potential of these ubiquitous heat exchangers has become a crucial priority.

Fortunately, the advent of advanced data analytics and machine learning (ML) technologies has ushered in a new era of air-cooled heat exchanger optimization. By integrating these cutting-edge tools into the design, engineering, and control strategies of air-cooled heat exchangers, we can now unlock unprecedented levels of performance, efficiency, and reliability.

In this comprehensive article, we will explore the transformative power of ML-driven optimization and control strategies in the realm of air-cooled heat exchangers. From enhanced design and manufacturing processes to real-time performance monitoring and adaptive control, we’ll delve into the latest advancements that are redefining the boundaries of what’s possible in thermal management.

Optimizing Air-Cooled Heat Exchanger Design with Machine Learning

The design of air-cooled heat exchangers is a complex and multifaceted endeavor, involving the careful consideration of factors such as airflow patterns, heat transfer coefficients, material selection, and geometric configurations. Traditionally, this design process has relied heavily on empirical data, trial-and-error approaches, and the expertise of seasoned engineers. However, the integration of ML-based techniques has revolutionized the way we approach air-cooled heat exchanger design.

One of the key advantages of using ML in the design process is the ability to accurately model and predict the performance of heat exchangers under various operating conditions. By leveraging advanced algorithms and vast datasets, ML-based models can capture the intricate relationships between design parameters and thermal-fluid dynamics, enabling engineers to explore a wider design space and identify optimal configurations.

For example, researchers have developed ML-enhanced control co-design optimization frameworks for battery thermal management systems that utilize air-cooled heat exchangers. These frameworks simultaneously optimize the heat exchanger’s plant design (e.g., fin geometry, tube spacing) and the control strategy (e.g., airflow rate, temperature setpoints) to minimize energy consumption while ensuring reliable thermal management. By considering the inherent uncertainties in the cooling equipment, these ML-driven approaches generate robust and reliable designs that can adapt to real-world operating conditions.

Similarly, research on machine learning for thermal transport has demonstrated the potential of ML-based surrogate models to streamline the design and optimization of air-cooled heat exchangers. These computationally efficient models can replace complex finite element simulations, enabling designers to rapidly explore a broader design space and identify optimal configurations that maximize heat transfer performance and minimize pressure drop.

Moreover, the integration of ML-based design optimization with uncertainty quantification has emerged as a powerful approach for developing air-cooled heat exchangers that are resilient to variations in environmental conditions, manufacturing tolerances, and operational parameters. By explicitly accounting for these uncertainties during the design phase, engineers can ensure that the heat exchangers deliver consistent and reliable performance, even in the face of changing or unpredictable operating environments.

Enhancing Air-Cooled Heat Exchanger Maintenance and Performance Monitoring with Machine Learning

While optimizing the design of air-cooled heat exchangers is crucial, maintaining their peak performance over time is equally important. Traditional maintenance strategies often rely on periodic inspections, reactive repairs, and rule-based control algorithms, which can be inefficient and fail to address the complex, nonlinear behavior of these systems.

Here, ML-based technologies are proving to be invaluable in revolutionizing air-cooled heat exchanger maintenance and performance monitoring. By leveraging advanced sensor networks, data analytics, and predictive modeling, ML-driven techniques can identify and address potential issues before they escalate, ensuring optimal performance and reliability.

One promising application of ML in this domain is predictive maintenance, where ML algorithms analyze sensor data to detect anomalies, predict equipment failures, and recommend proactive maintenance actions. This approach can help plant operators and maintenance teams anticipate and address problems, such as fouling, corrosion, or mechanical degradation, before they lead to unplanned downtime or reduced efficiency.

Furthermore, ML-based control strategies can dynamically adapt the operation of air-cooled heat exchangers to changing environmental conditions and system requirements. By continuously monitoring parameters like airflow, inlet temperatures, and heat transfer rates, these intelligent control systems can adjust key variables, such as fan speed and air damper positions, to maintain optimal performance and energy efficiency.

In the context of industrial facilities, integrating ML-powered predictive maintenance and adaptive control into the management of air-cooled heat exchangers can result in significant cost savings, reduced maintenance expenses, and improved system reliability. By minimizing unplanned downtime and ensuring consistent thermal performance, these ML-driven strategies contribute to the overall sustainability and competitiveness of industrial operations.

Advancing Air-Cooled Heat Exchanger Applications through Machine Learning

Beyond design optimization and performance management, ML is also transforming the way we approach air-cooled heat exchanger applications across diverse industries. By integrating ML-based techniques, engineers and operators can unlock new levels of efficiency, flexibility, and adaptability in thermal management systems.

In the power generation sector, for instance, ML-powered control strategies have been employed to optimize the performance of air-cooled condensers used in thermal power plants. By continuously monitoring and adjusting parameters like airflow, fan speed, and heat transfer rates, these intelligent control systems can enhance energy efficiency, reduce operational costs, and ensure reliable operation during peak demand periods.

Similarly, in the HVAC industry, ML-based algorithms are being leveraged to enhance the performance and energy efficiency of air-cooled heat exchangers used in commercial and residential cooling systems. By analyzing real-time data on temperature, humidity, and occupancy patterns, these ML-driven control systems can dynamically adjust the operation of air-cooled heat exchangers, leading to substantial energy savings and improved indoor comfort.

In the petrochemical and industrial manufacturing domains, air-cooled heat exchangers play a crucial role in process cooling and waste heat recovery. Here, ML-based models and control algorithms are being employed to optimize heat exchanger performance, minimize energy consumption, and enhance the overall efficiency of these critical thermal management systems.

For example, researchers have developed ML-based strategies for the optimal control of air-cooled heat exchangers in industrial waste heat recovery applications. These approaches leverage real-time data and predictive models to dynamically adjust the operation of the heat exchangers, ensuring that the maximum amount of waste heat is recovered and utilized, leading to significant energy savings and reduced environmental impact.

As the application landscape for air-cooled heat exchangers continues to expand, the integration of ML-based technologies will be instrumental in unlocking new levels of performance, efficiency, and flexibility. From power generation and HVAC to industrial processing and beyond, the synergistic integration of air-cooled heat exchangers and ML-driven optimization and control strategies will be a driving force in shaping the future of thermal management systems.

Conclusion: Embracing the Future of Air-Cooled Heat Exchangers with Machine Learning

The marriage of air-cooled heat exchangers and machine learning has ushered in a new era of thermal management, where advanced data analytics and intelligent control strategies are redefining the boundaries of what’s possible. By seamlessly integrating ML-based techniques into the design, maintenance, and application of air-cooled heat exchangers, we can unlock unprecedented levels of performance, efficiency, and reliability.

From optimizing heat exchanger configurations to enhancing predictive maintenance and adaptive control, the integration of ML has revolutionized the way we approach thermal management challenges. As the demand for energy-efficient and sustainable solutions continues to grow, the synergistic collaboration between air-cooled heat exchangers and ML-powered technologies will be instrumental in shaping the future of thermal management systems.

By embracing the transformative power of machine learning, air-cooled heat exchanger professionals can now design, maintain, and apply these ubiquitous systems with unparalleled precision and responsiveness. As the industry continues to evolve, the experts at Air Cooled Heat Exchangers remain at the forefront, leveraging the latest advancements in ML to push the boundaries of what’s achievable in the realm of thermal management.